Positioning device for welding automobile parts

A technology for auto parts and positioning devices, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of complex fixture design, poor solder joint accessibility, etc., to achieve good solder joint accessibility, guarantee accuracy, Lap Stable Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

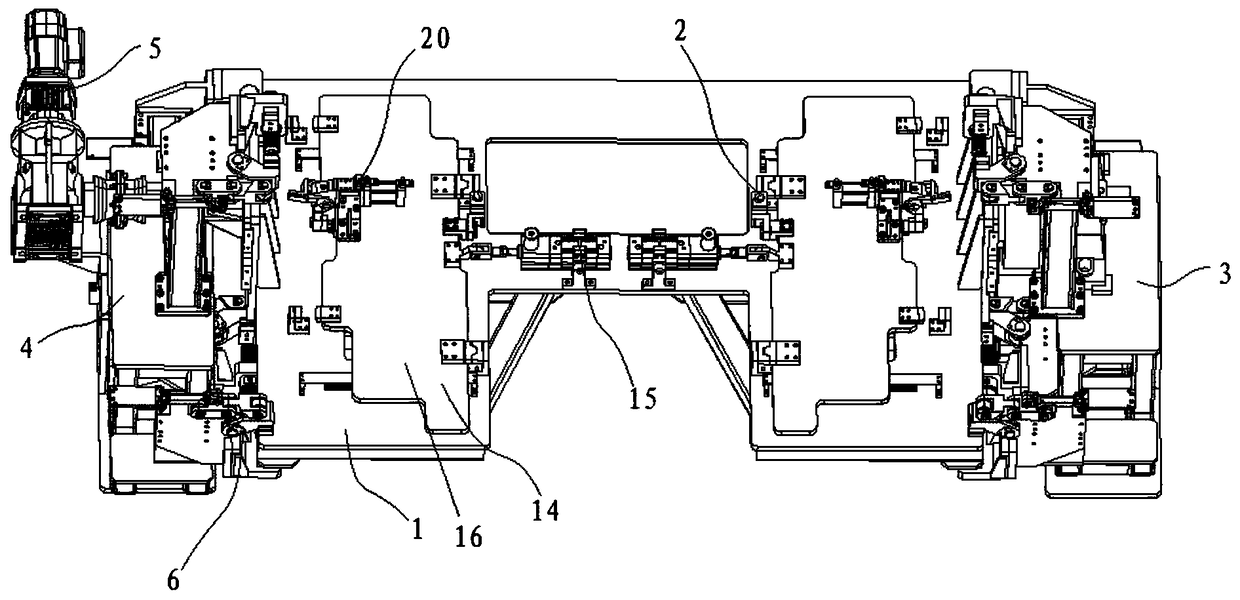

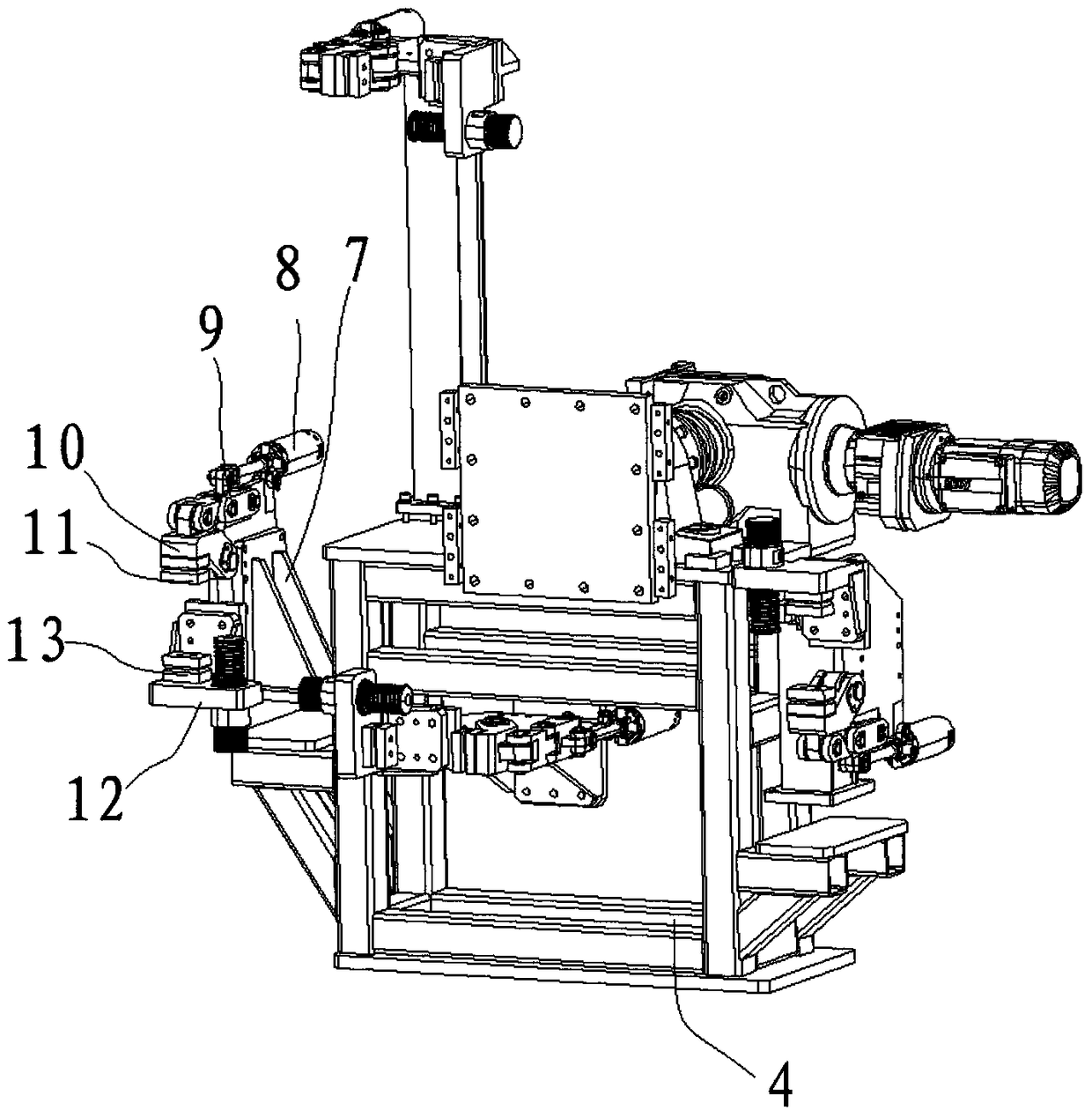

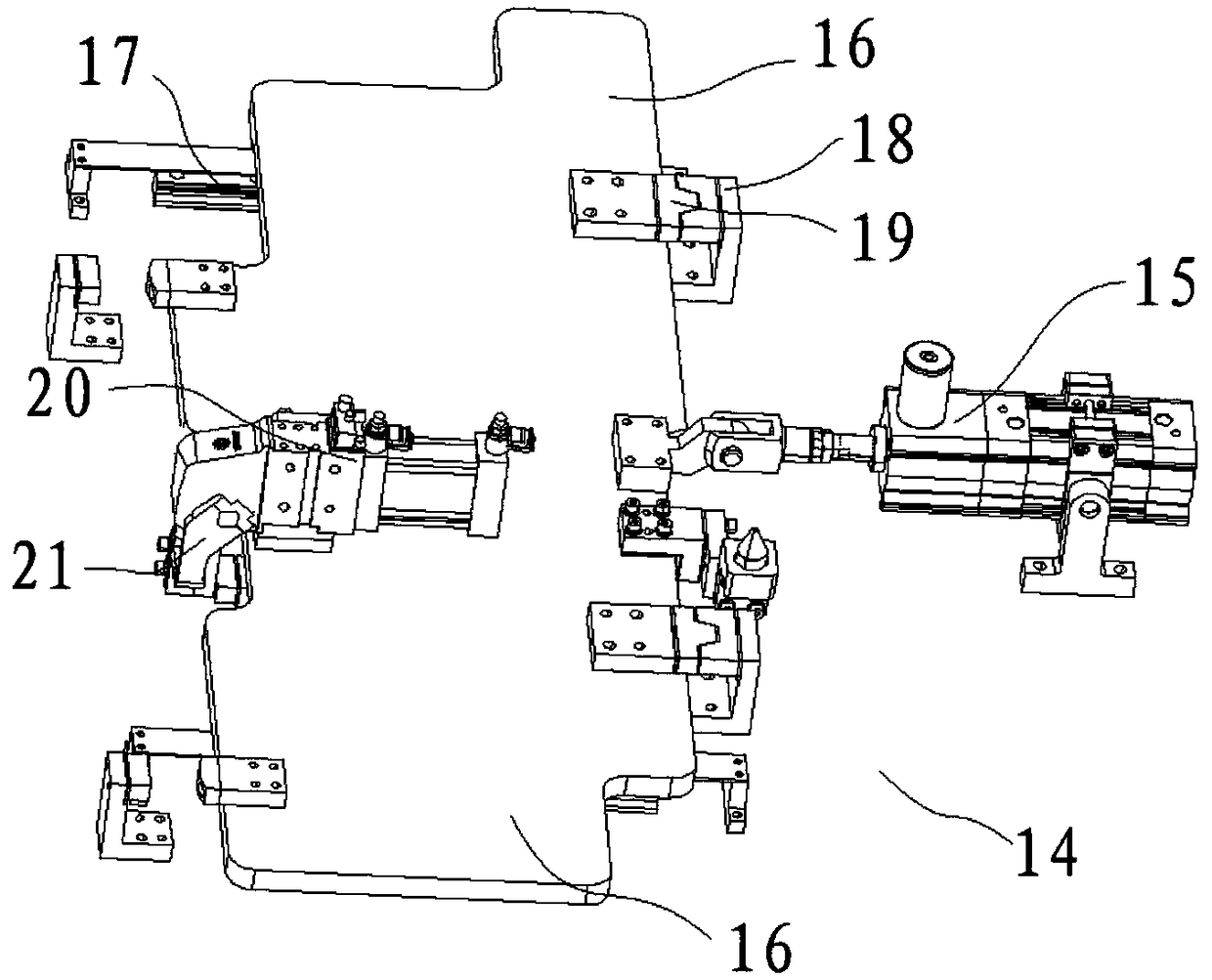

[0022] like Figure 1 to Figure 3 As shown, embodiments of the present invention provide a positioning device for welding of auto parts, including:

[0023] The base plate 1 provides a bearing surface for bearing and fixing parts to be welded.

[0024] The tool positioning mechanism is arranged on the base plate 1, and the tool positioning mechanism is provided with a positioning pin 2, and the positioning pin 2 is used for positioning to improve the stability of the overlapping structure of parts and ensure the accuracy.

[0025] The rotary positioning mechanism is connected with the substrate 1 and drives the substrate 1 to rotate to multiple working states. The inclination angle of the substrate 1 in each working state is different, thereby adjusting the welding angle of the workpiece to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com