A kind of polyurethane foaming improvement process

A polyurethane and process technology, which is applied in the field of polyurethane foam improvement process, can solve the problems of low polyurethane foaming efficiency and poor foaming effect, and achieve the effect of accelerating the foaming rate, strengthening the stirring effect, and fully uniform foaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

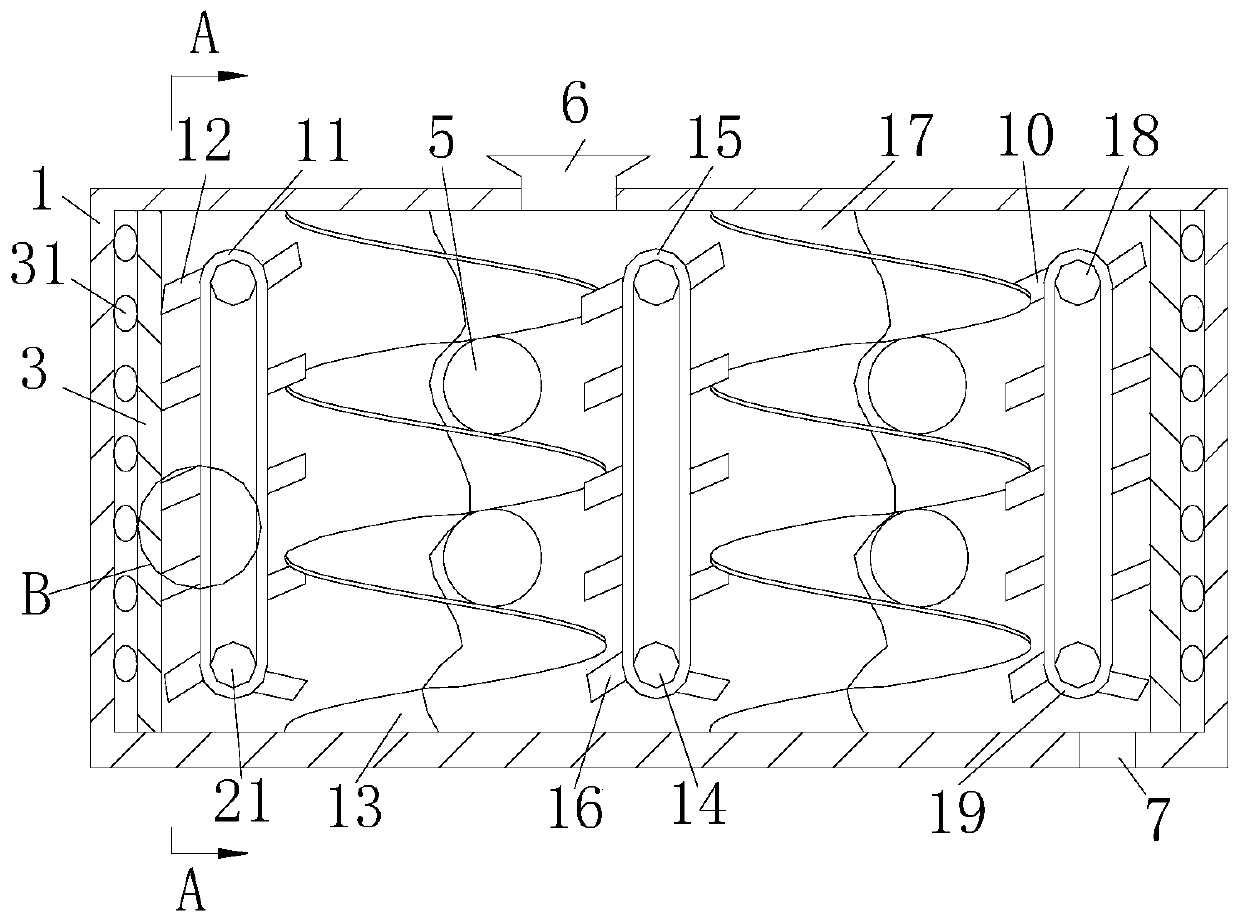

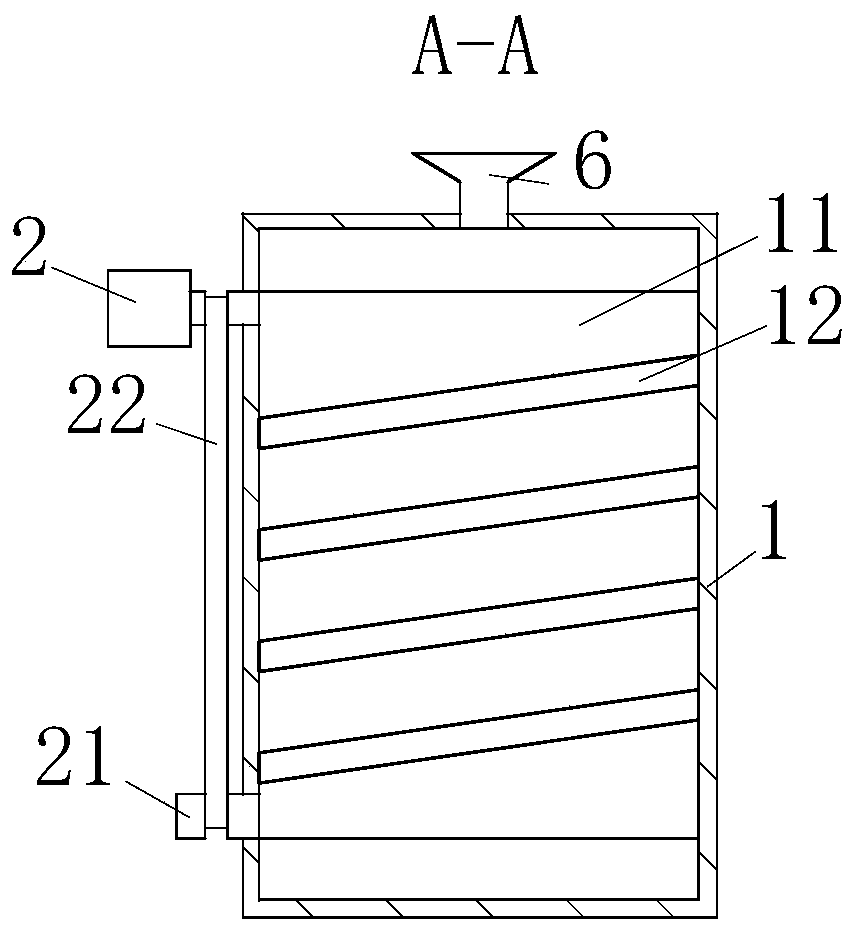

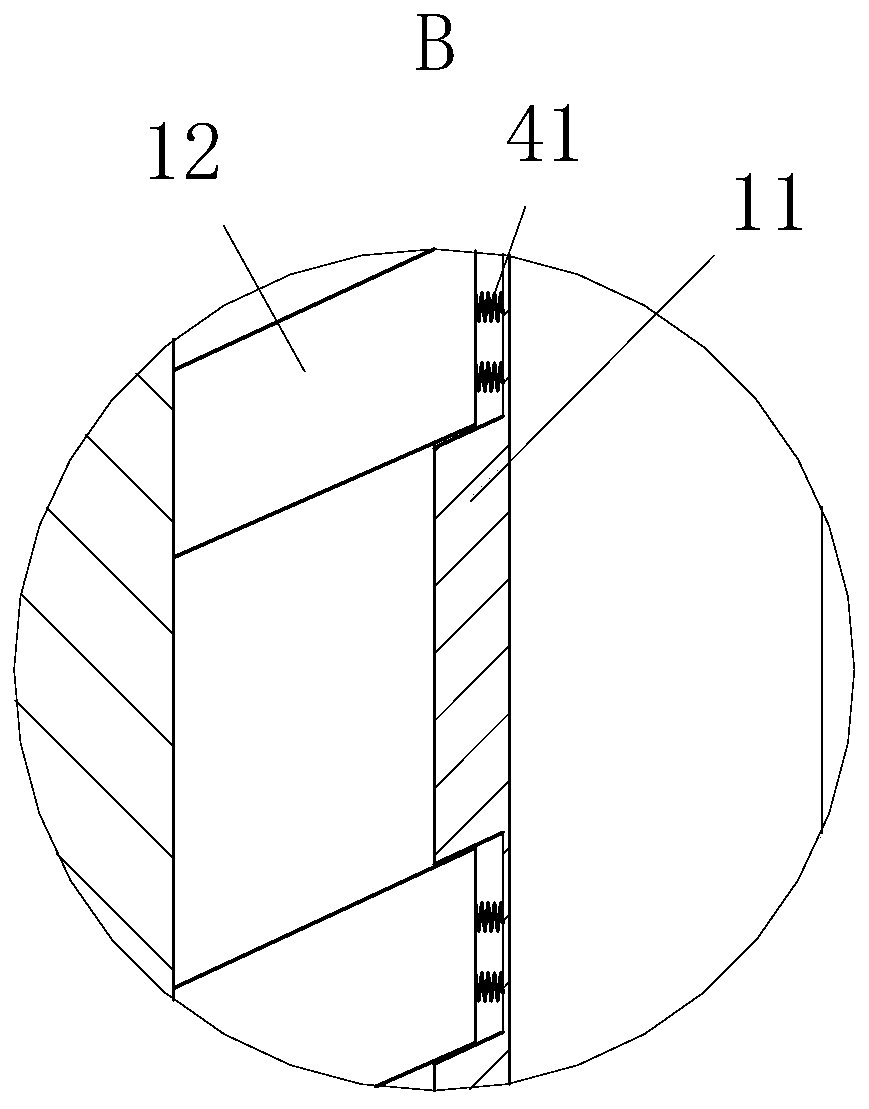

[0030] As an embodiment of the present invention, the first bump 12, the second bump 16 and the third bump 10 are all inclined; the surfaces of the second belt 11, the third belt 15 and the fourth belt 19 are provided with Groove 4, the first bump 12, the second bump 16 and the third bump 10 are located in the groove 4 respectively, and are connected with the bottom of the groove 4 by the spring 41; , The second bump 16 and the third bump 10 make the stirring more complete, and the foaming rate of the polyurethane is faster, through the setting of the spring 41, and the first bump 12 and the third bump 10 squeeze the extruding plate 3 during rotation , so that the extrusion plate 3 shakes, so that the polyurethane in the frame body 1 flows, the stirring effect is enhanced, and the foaming of the polyurethane is accelerated.

[0031] As an embodiment of the present invention, the first airbag 31 is provided with air holes that communicate with the outside world and the frame bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com