pneumatic tire

A technology of pneumatic tires and tires, which is applied in the field of pneumatic tires and can solve problems such as wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

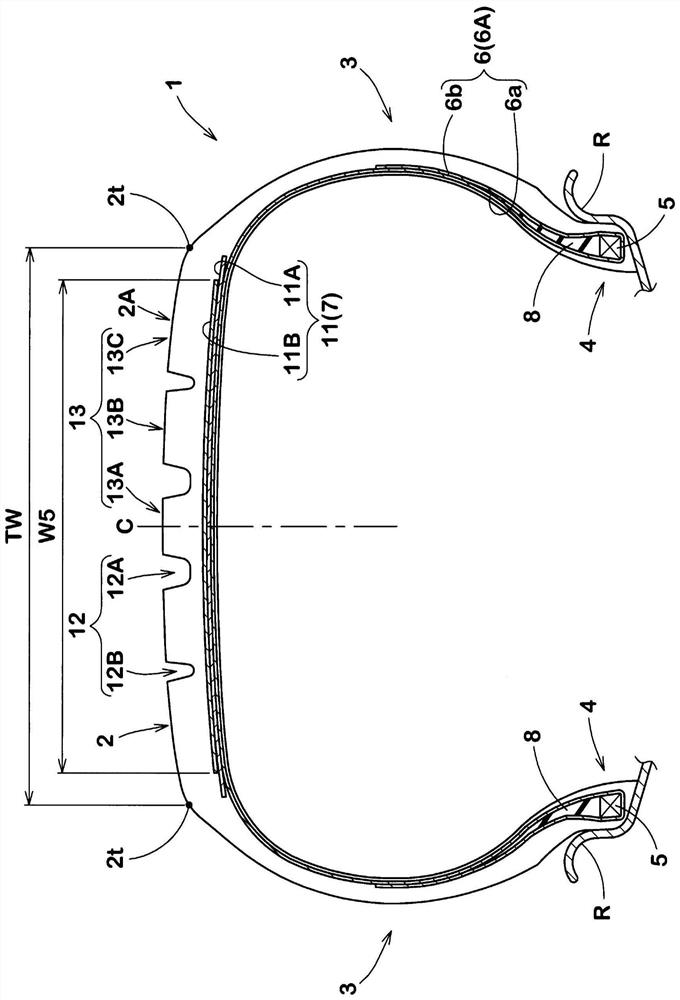

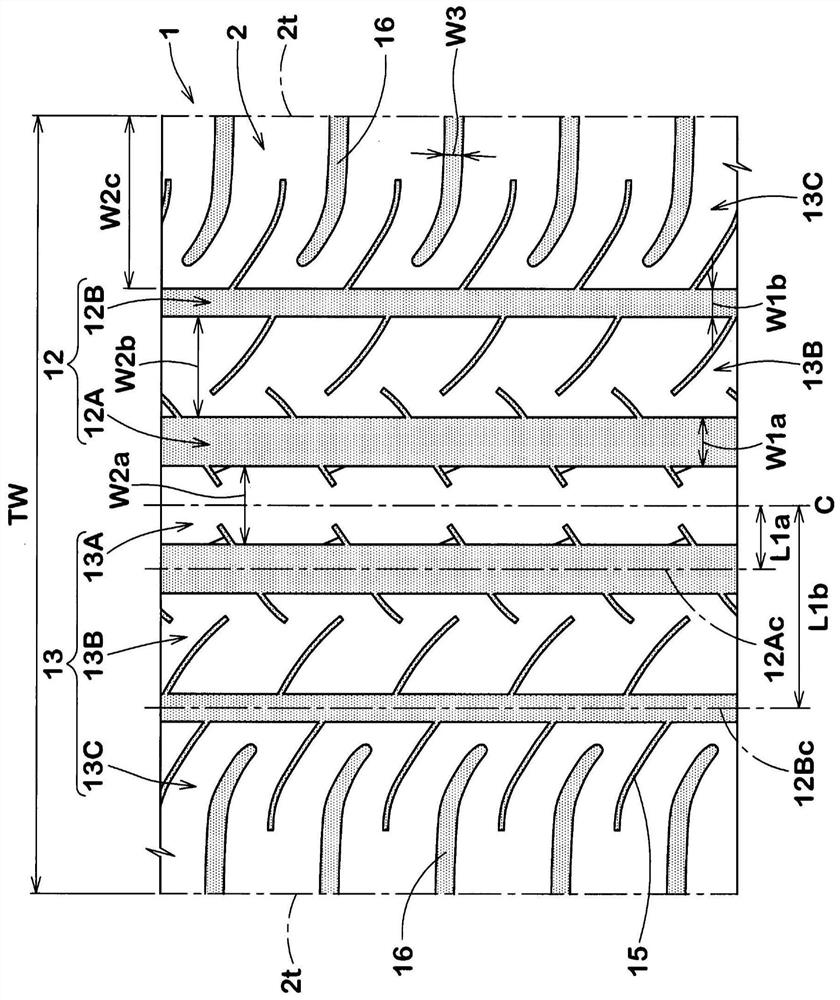

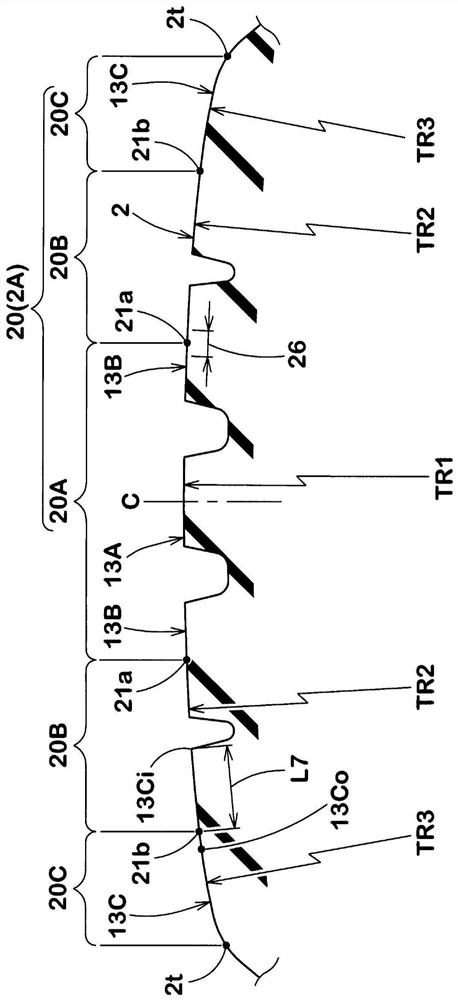

[0065] produced with figure 1 The basic structure shown in Table 1 shows the position of the maximum ground contact length portion, the outer belt ply and the profile of the tread portion (the first radius of curvature TR1, the second radius of curvature TR2, the Three tires with different curvature radii TR3) were used to evaluate their performance (Examples 1-8, Comparative Examples 1 and 2). The position of the part of the maximum ground length is in the grounded state with a camber angle of 3°, such as Figure 5 As shown, it is represented by the ratio L6 / Wm of the distance L6 from the central position of the contact patch to the side in the first direction in the tire axial direction to the maximum width Wm of the contact patch. The specifications common to each Example and Comparative Example are as follows.

[0066] Tire size: 195 / 65R15

[0067] Rim size: 15×6.0J

[0068] Internal pressure: 230kPa

[0069] Load: 4.22kN

[0070] Vehicle: Displacement 2000cm 3 Japa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com