Single row to double row bottle pushing transfer mechanism

A round bottle and push rod technology, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems that single rows cannot be converted into double rows, etc., to increase the function of bottle separation, stable operation, and smooth operation speed accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

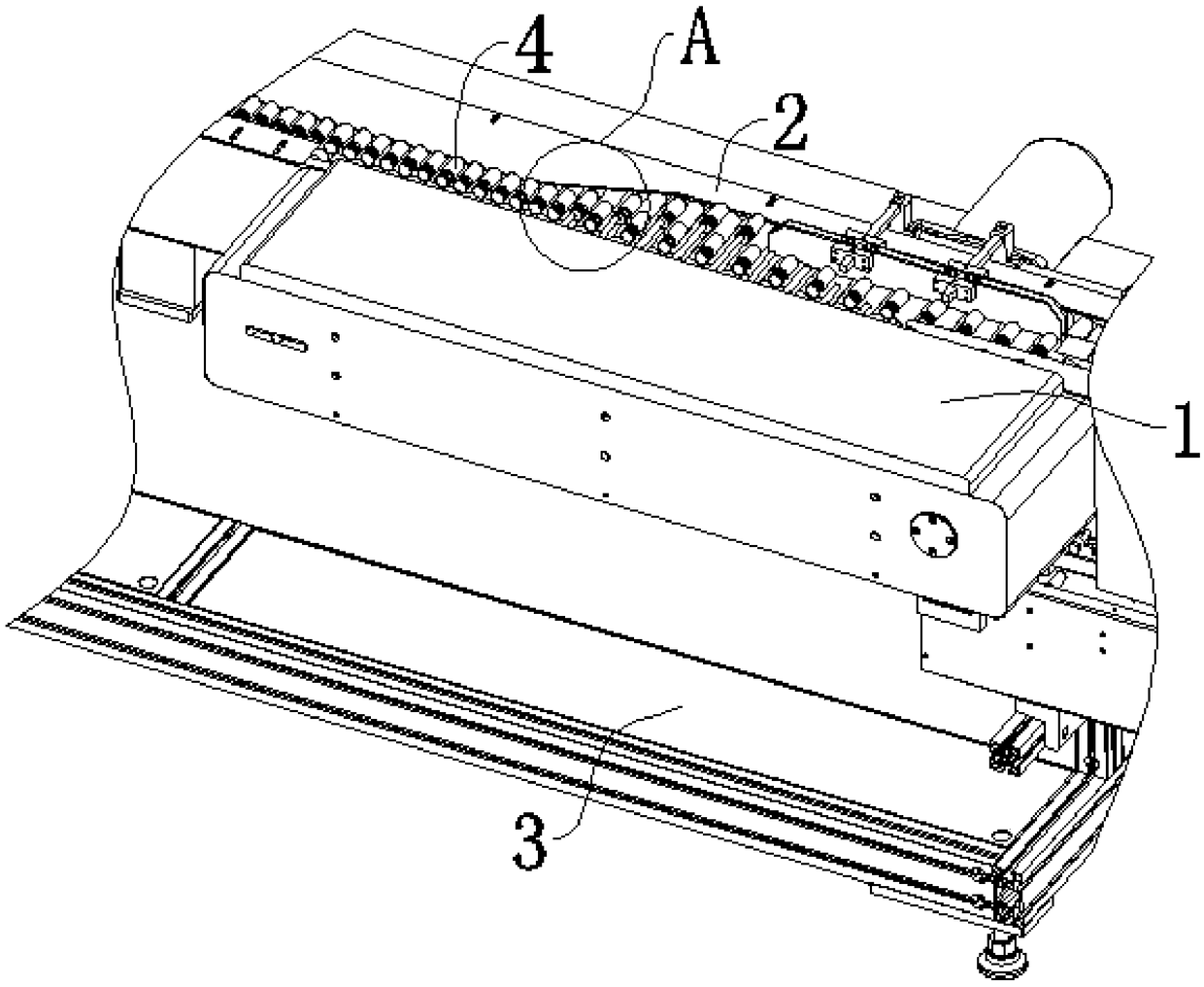

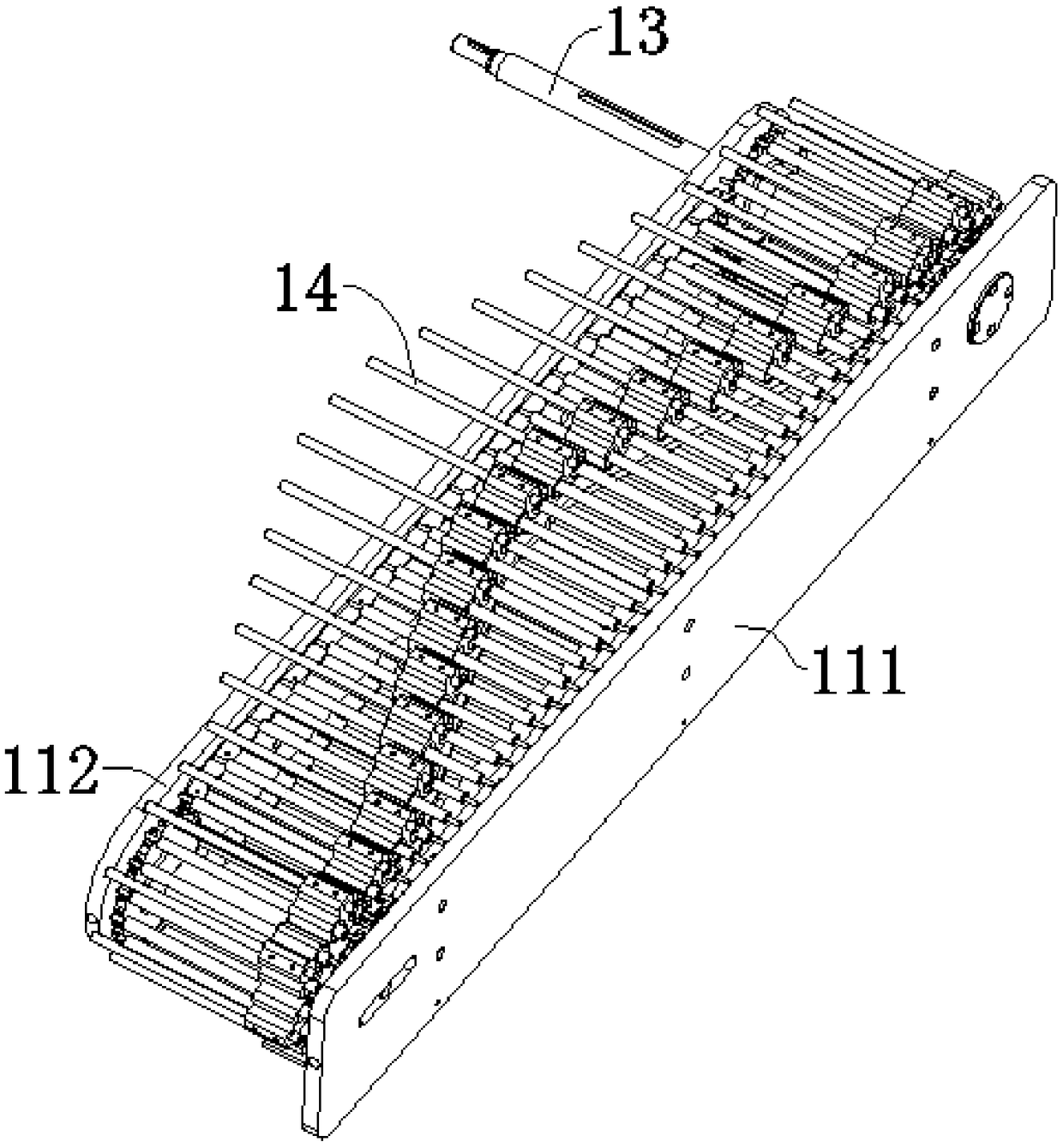

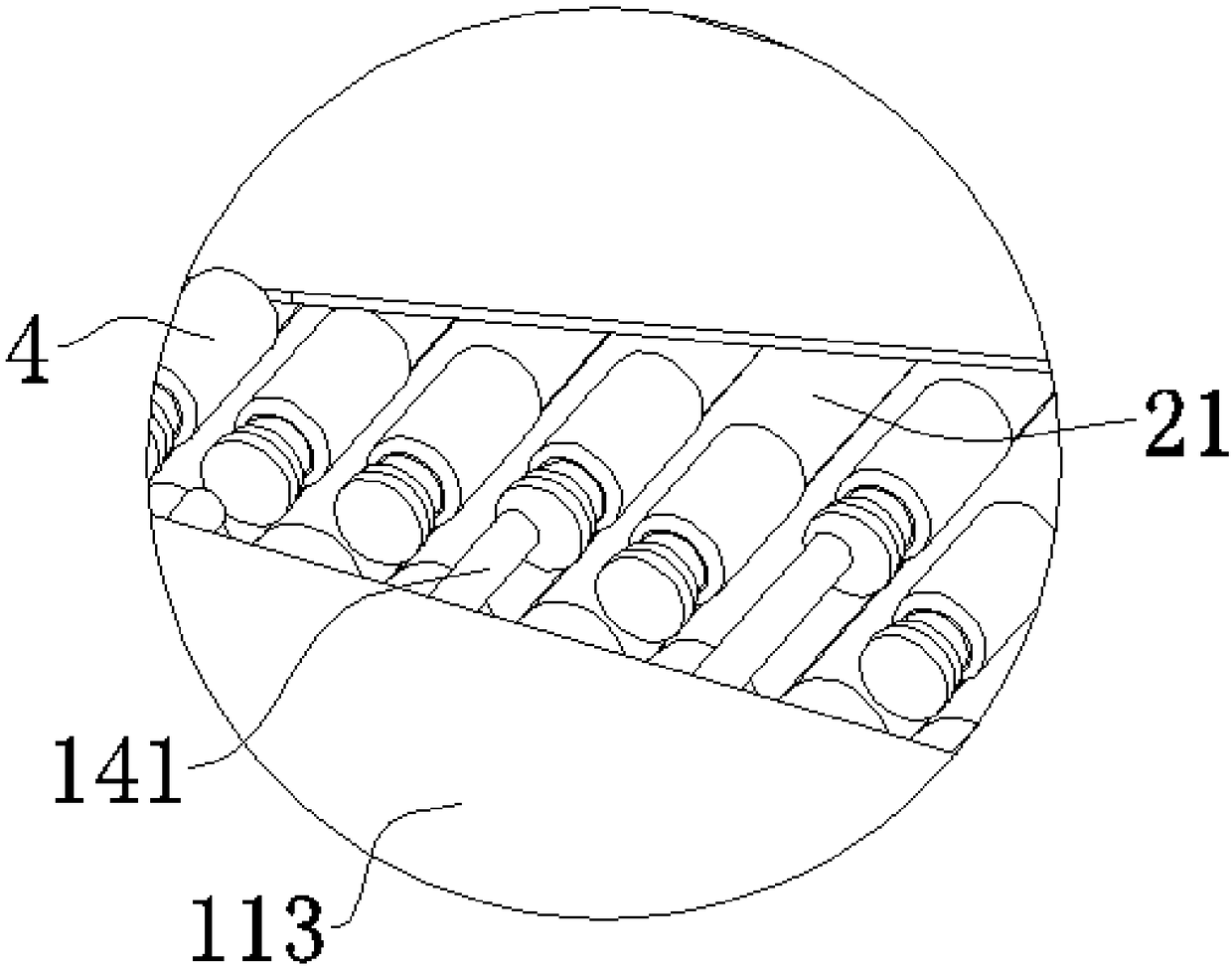

[0035] Embodiment: a kind of single-row to double-row push bottle transfer mechanism, such as figure 1 , 2 , 3, 4, 5, and 6, including bottle pushing mechanism 1, which is installed on the labeling and supporting machine and used to separate the single row of round bottles 4 into double rows, and the labeling and supporting machine is equipped with a conveyor Device 2, conveying device 2 adopts roller conveying mode and is used for horizontally conveying round bottles 4 to realize labeling, bottle pushing and traying. The conveying device 2 includes a motor and several conveying rollers 21. The two ends of the conveying rollers 21 are provided with conveying sprockets, and the conveying sprockets are covered with conveying chains engaged with them. The transmission chain is driven by a motor, and the motor is installed on the labeling and supporting integrated machine. The round bottle 4 is horizontally placed on the upper surface of the transmission roller 21 and is located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com