A stirring method for improving the dissolved oxygen of fermented liquid in a liquid fermenter

A liquid fermentation and stirring method technology, applied in the field of fermentation tanks, can solve the problems of small gas specific gravity, low dissolved oxygen efficiency, low efficiency, etc., and achieve the effects of reducing shear damage and enhancing dissolved oxygen efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

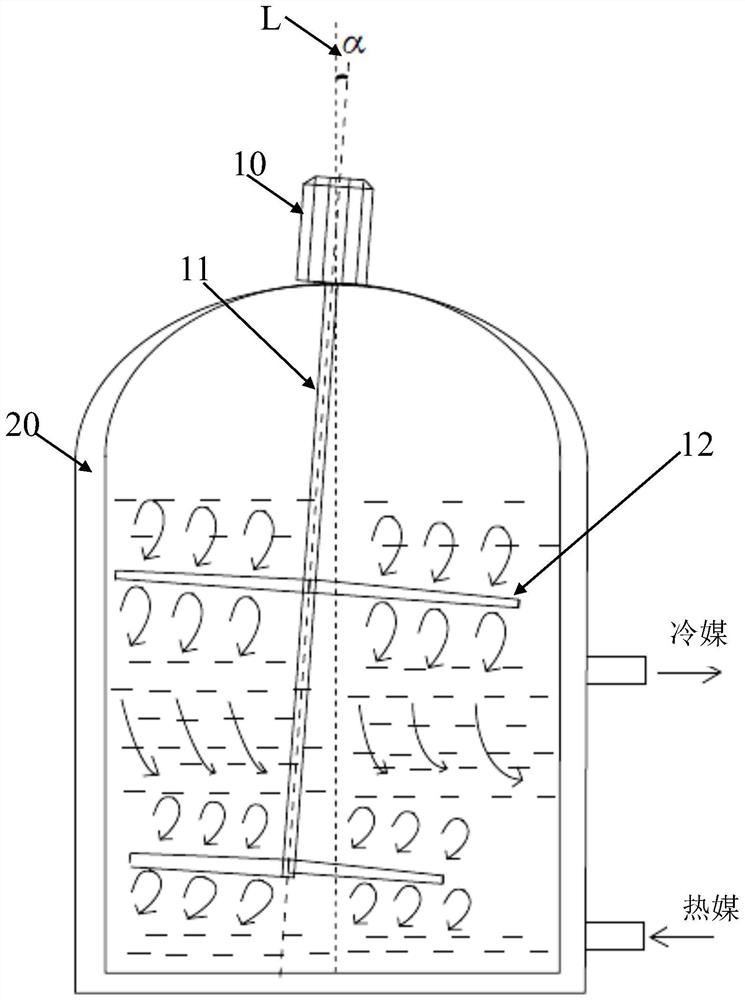

[0031] see figure 2 As shown, it is a fermenter high-efficiency dissolved oxygen stirrer 10 of a preferred embodiment of the present invention, which is installed in the fermenter 20 and includes a stirring shaft 11, and the stirring shaft 11 is installed at an inclination angle α relative to the central axis L of the fermenter In the fermenter 20, the inclination angle α is 1~2° or 2~4° or 4~5°, such as figure 2 2° shown.

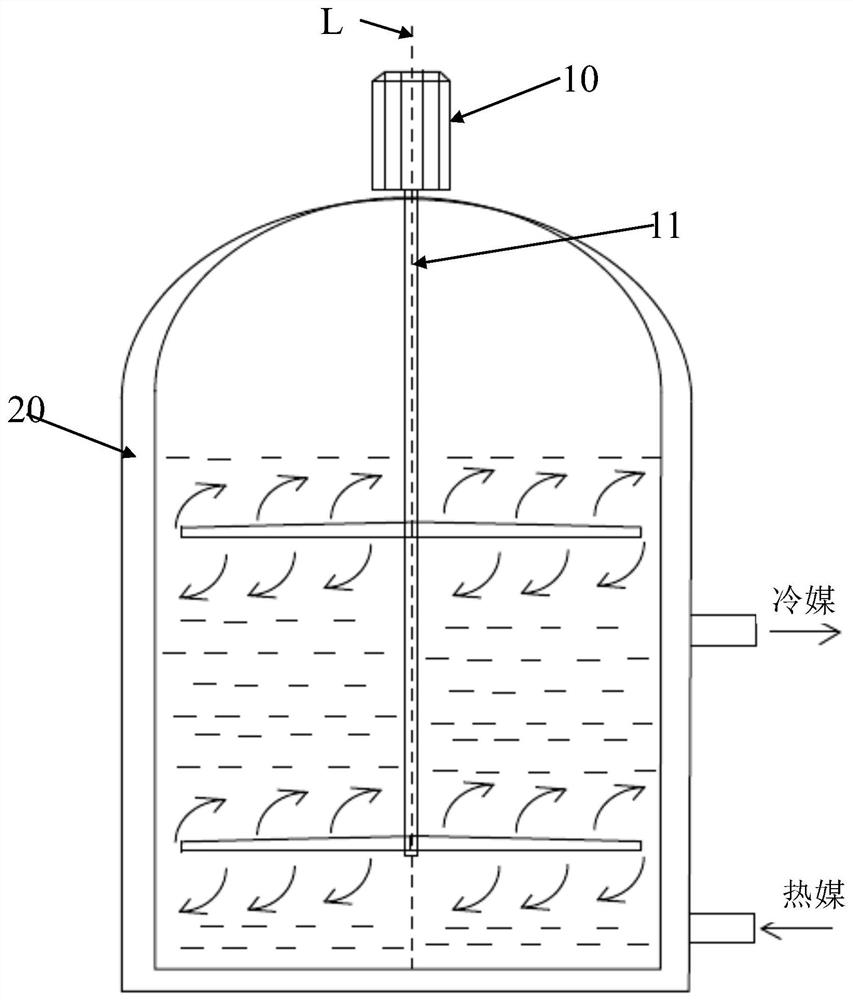

[0032] combine figure 1 , Figure 4 , Figure 5 As shown, the agitator 10 also includes a multi-layer blade 12, and the blade 12 is a multi-layer propeller blade. The multi-layer propeller blade 12 is that the blades 121 of each layer are arranged into one layer along the helical line, but each layer is a separate shape (such as Figure 4 ); or each blade 121 is arranged in a form connected end to end from top to bottom along a helical line (such as Figure 5 ), the paddle 12 can be provided with 1 to 10 layers, preferably 2 to 5 layers. Preferabl...

Embodiment 2

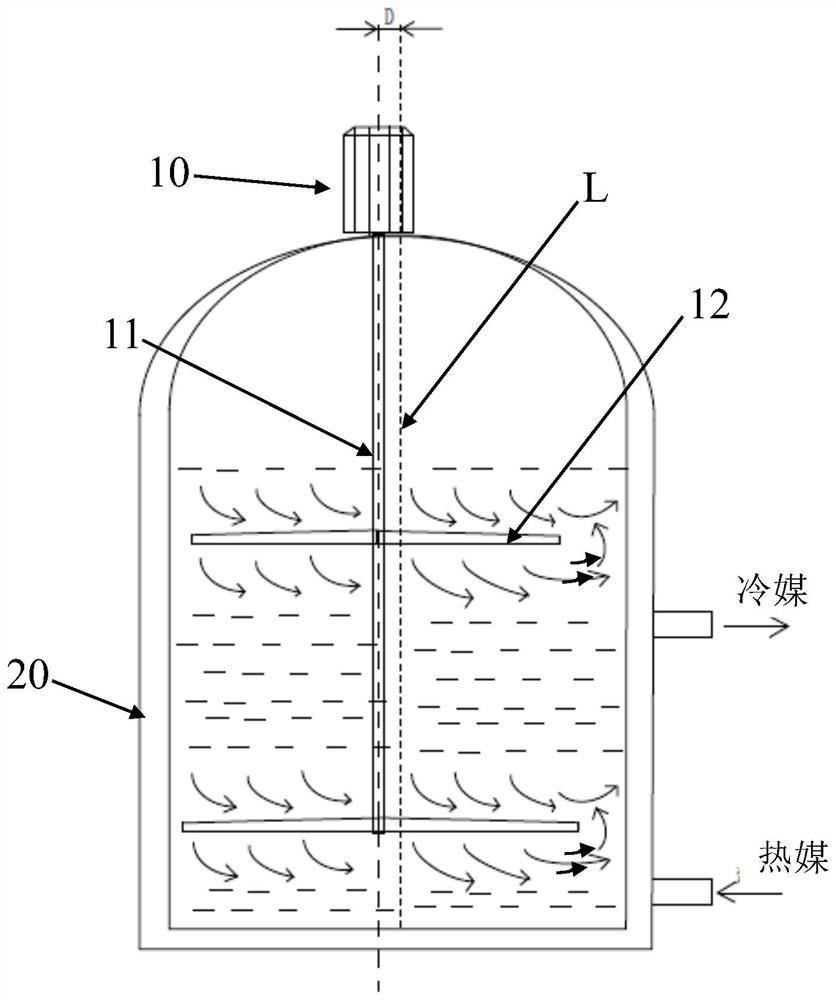

[0036] see image 3 As shown, it is a high-efficiency dissolved oxygen stirrer 10 for a fermenter in a preferred embodiment of the present invention, which is installed in a fermenter 20 and includes a stirring shaft 11. The stirring shaft 11 is relatively deviated from the central axis L of the fermenter and installed in the fermenter. In 40, the deviation D is about 2%-3% or 3-4% of the diameter of the fermenter, more preferably 1 / 40.

[0037] combinefigure 1 , Figure 4 , Figure 5 As shown, the agitator 10 of this embodiment includes multi-layer paddles 12, and the paddles 12 are multi-layer propeller blades. The multi-layer propeller blade 12 is that the blades 121 of each layer are arranged into one layer along the helical line, but each layer is a separate shape (such as Figure 4 ); or each blade 121 is arranged in a form connected end to end from top to bottom along a helical line (such as Figure 5 ), the paddle 12 can be provided with 1 to 10 layers, preferably ...

Embodiment 3

[0042] For the structural design, size and rotational speed of the blade 12 and blade 121 in this embodiment, refer to Embodiment 1-2. In this embodiment, on the basis of the above-mentioned embodiments, the stirring shaft 11 is deviated from the central axis L of the fermenter by a certain distance and installed at an inclination angle α relative to the central axis L at the same time, and the inclination angle is 1-2° or 2-4° Or 4-5°, the deviation distance D is about 2%-3% or 3-4% of the diameter of the fermenter. Since these two technical features can be combined without conflicting, conflicting or counteracting effects, the technical effects and working principles of this embodiment can be superimposed with reference to the relevant descriptions of Embodiment 1-2, which will not be tolerated here. Let me repeat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com