Light-emitting diode (LED) lamp butt-joint plug

A technology of LED lamps and plugs, which is applied in the direction of lighting devices, light sources, parts of lighting devices, etc., can solve the problems of hindered promotion and application of market products, difficult standardization, and long time-consuming, so as to achieve safe and reliable electrical connection, improve Use reliability, fast installation and maintenance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

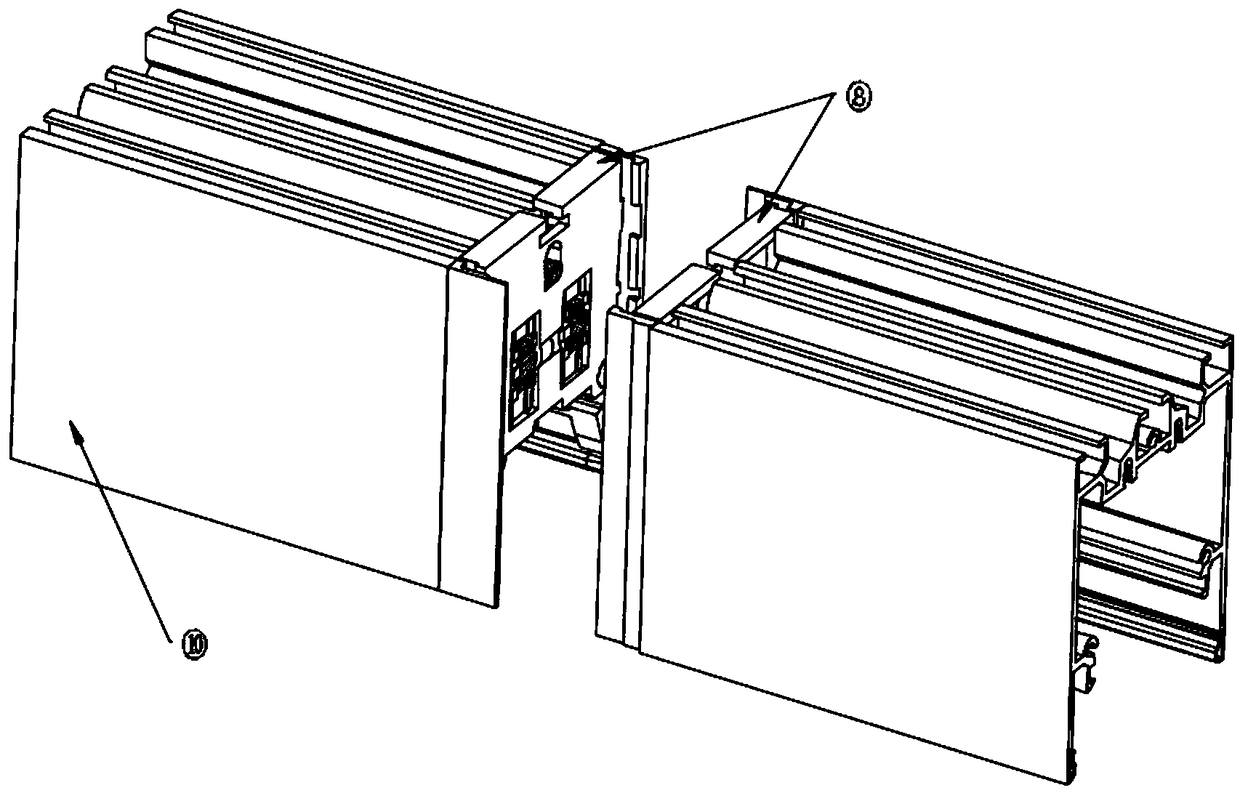

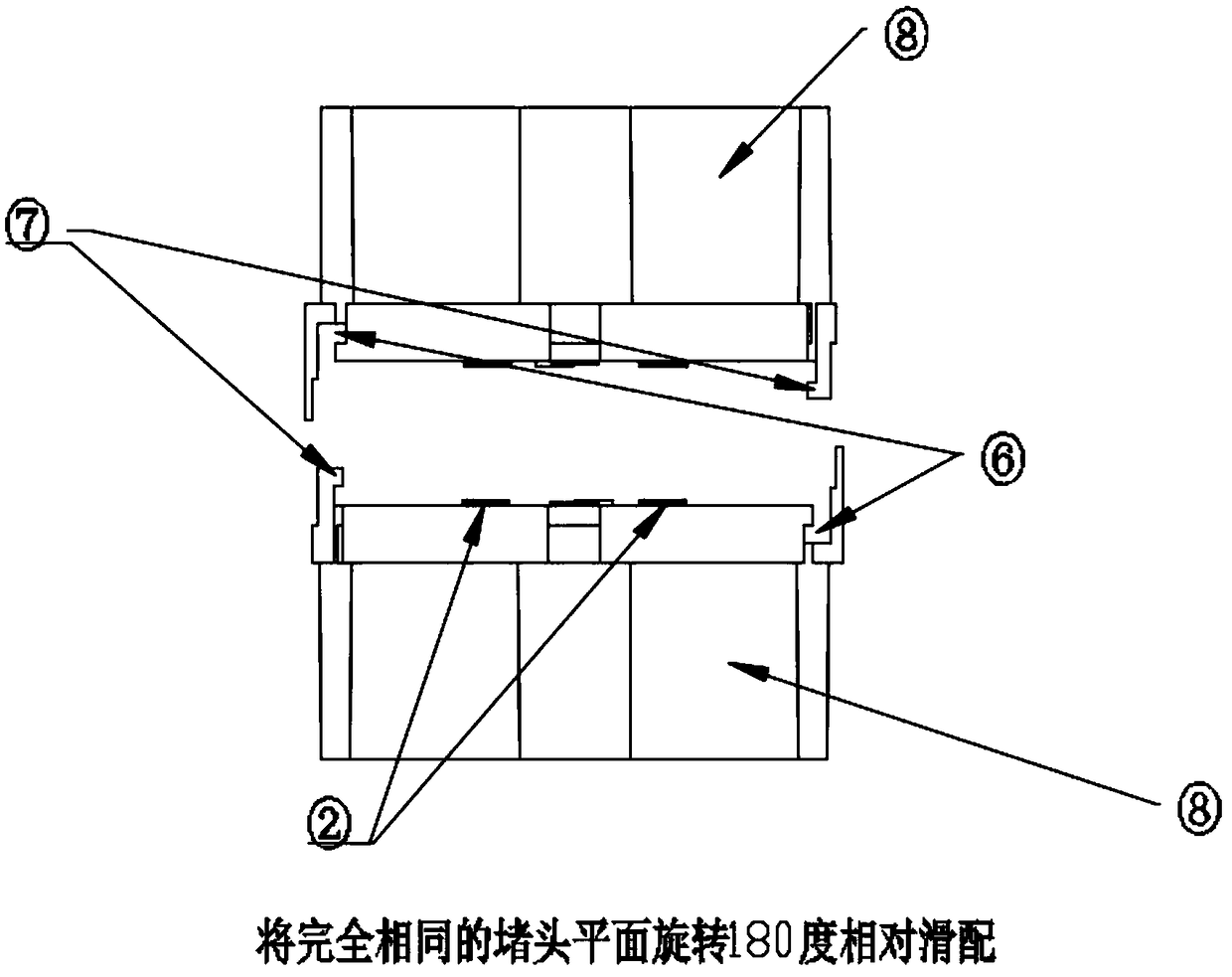

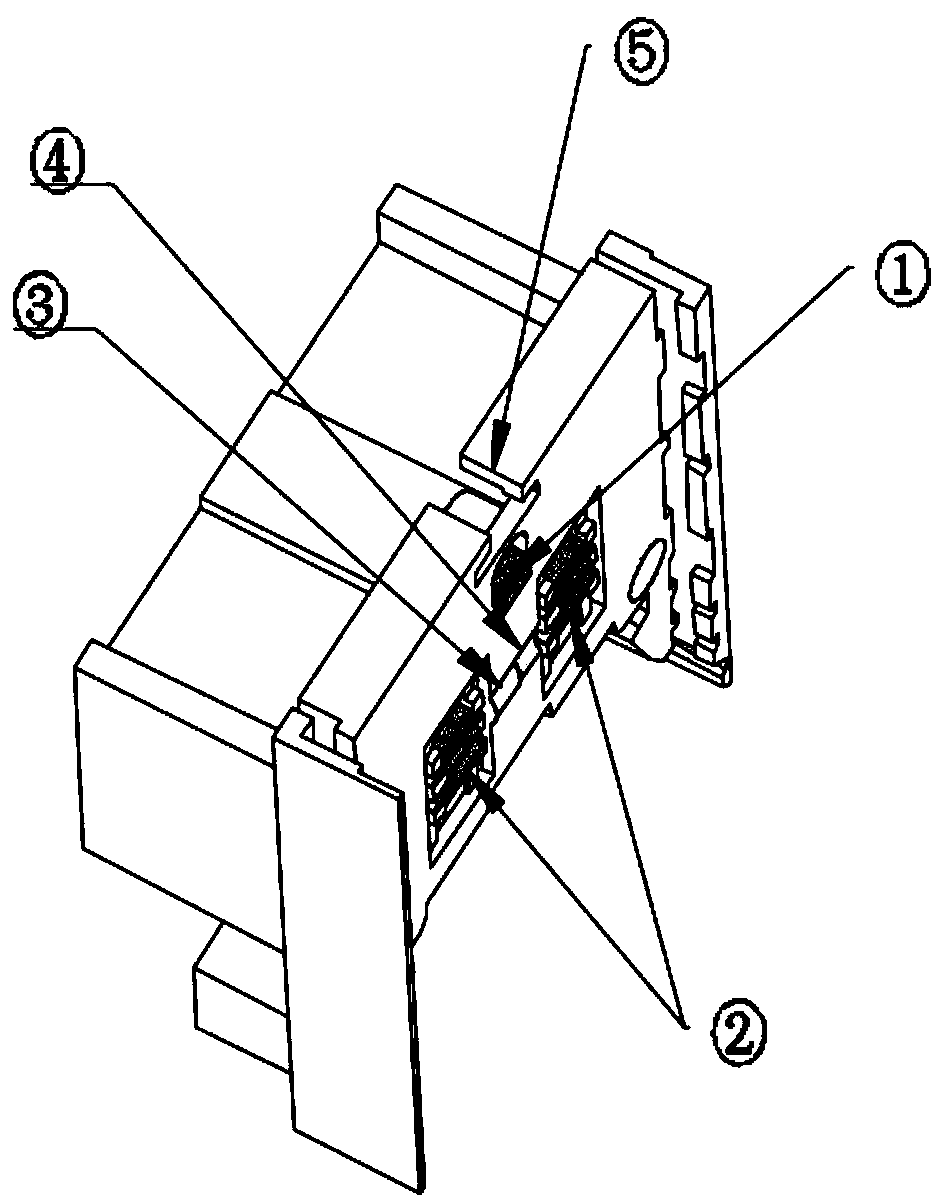

[0019] Such as figure 1 As shown, the LED lamp butt joint plug of the present invention includes two sets of lamp main bodies 10, the ends of the two sets of lamp main bodies 10 are provided with butt joint plugs 8, and at least one One set of sliding fitting grooves 6 and at least one set of sliding fitting ribs 7, the sliding fitting groove group 1 and the sliding fitting rib group 2 on the same butt joint plug 8 are complementary sliding mating settings, the butt joint surfaces of two sets of butt joint plugs 8 There are positioning concave points 4 and positioning convex points 3 on the top, and the corresponding parts of two identical butt plugs face to face form com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com