Integrated inspection tool for single stamping part and welding assembly

An assembly and inspection tool technology, which is applied in the direction of measuring devices, instruments, and mechanical devices, etc., can solve the problem of different storage locations for stamping single-piece inspection tools and welding assembly inspection tools, inconvenient troubleshooting, and difficulty in quickly troubleshooting the cause of problems and other problems to achieve the effect of saving the debugging cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

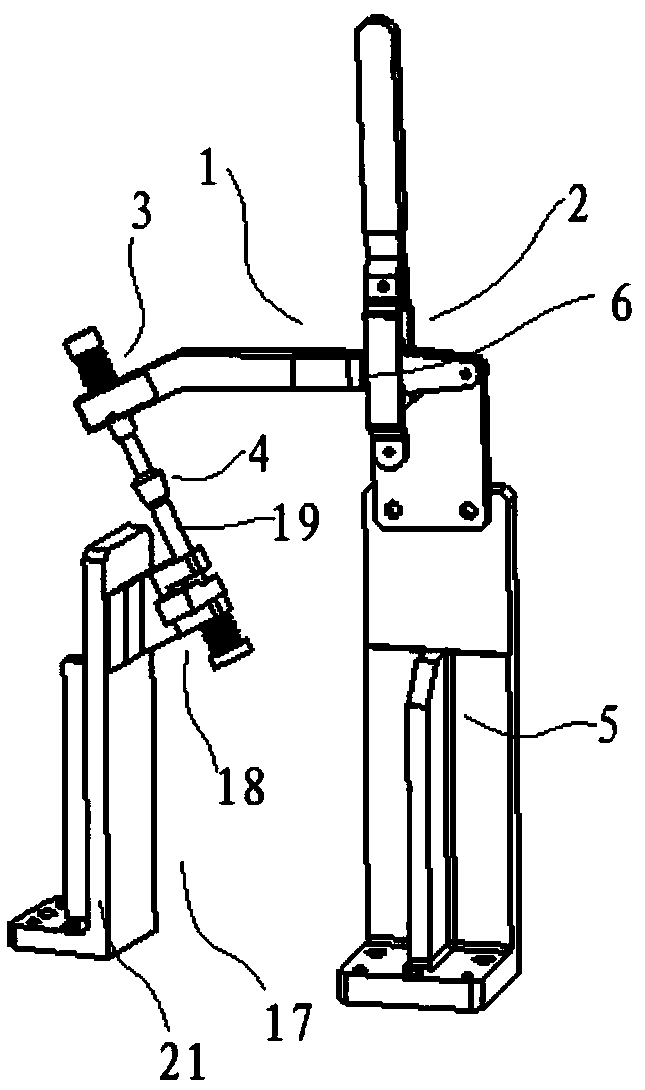

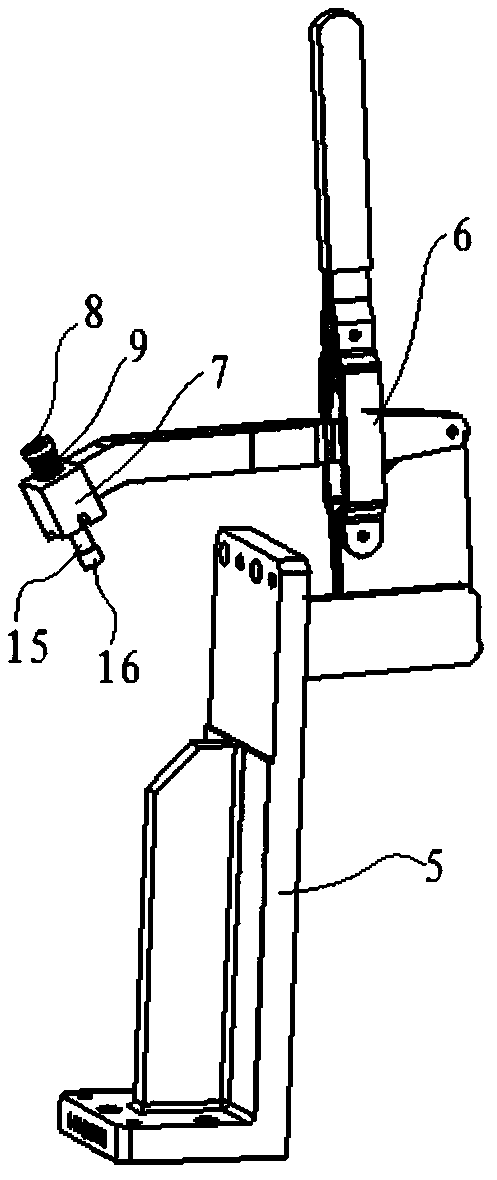

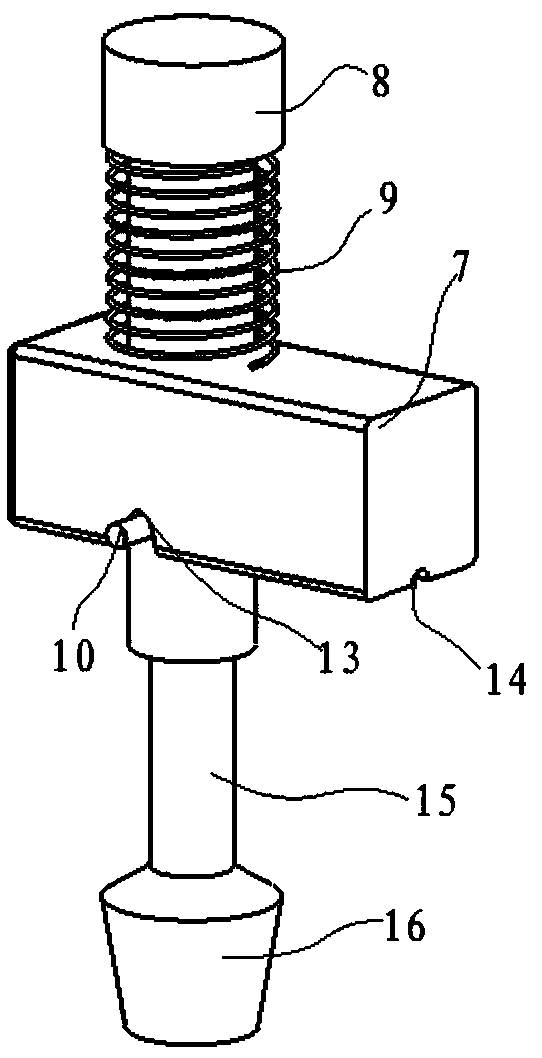

[0034] Such as figure 1 As shown, the embodiment of the present invention provides a stamping single-piece and welding assembly integrated inspection tool, including a clamping unit 1 and a support unit 17 arranged opposite to the clamping unit 1, wherein:

[0035] The clamping unit 1 includes a driving part 2, a first switching part 3 and a clamping part 4, the first switching part 3 is connected with the clamping part 4, and is used to switch the clamping part 4 between multiple To switch between clamping positions, the driving member 2 is connected to the first switching member 3 to drive the clamping member 4 to clamp the part to be measured on the support unit 17 .

[0036] The supporting unit 17 includes a supporting member 18 and a second switching member 19, the supporting member 18 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com