A cable bridge for easy maintenance

A technology of cable trays and operating slots, applied in the direction of electrical components, etc., can solve the problems of limited number of cables, cumbersome and inconvenient cable operations, and achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

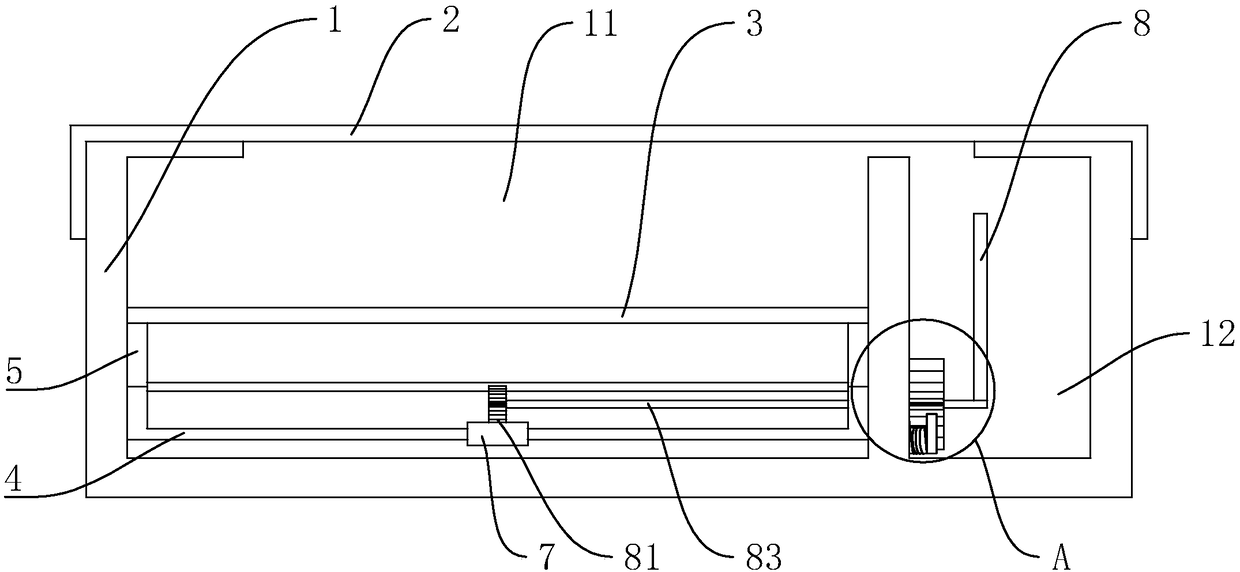

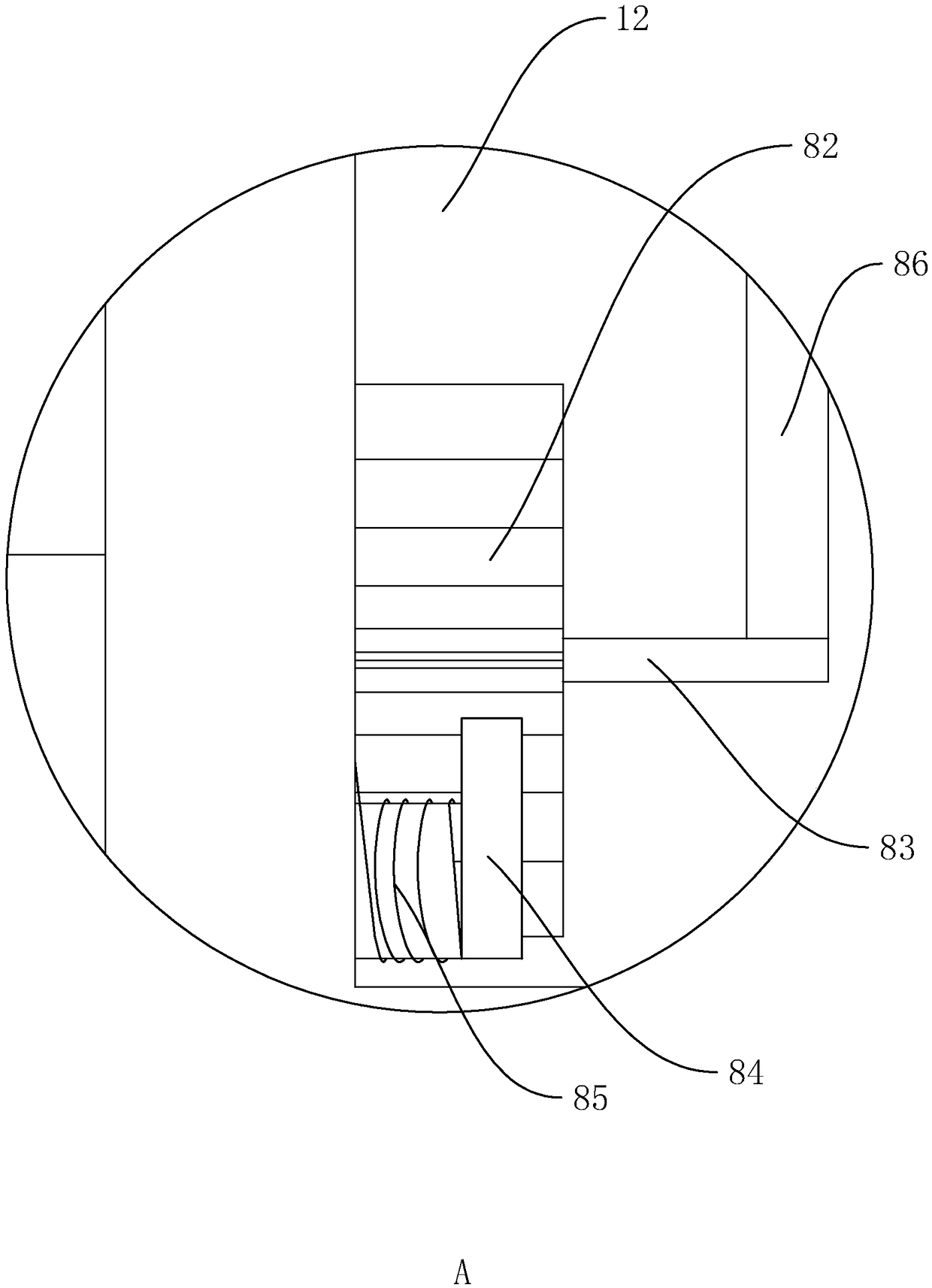

[0022] This embodiment provides an easy-to-maintain cable tray, the structure of which is as follows figure 1 , including a tank body 1 and a cover plate 2 covering the tank body 1 , the tank body 1 is divided into a wire slot 11 and an operation slot 12 along its width direction, and the width of the wire slot 11 is set to be greater than the width of the operation slot 12 .

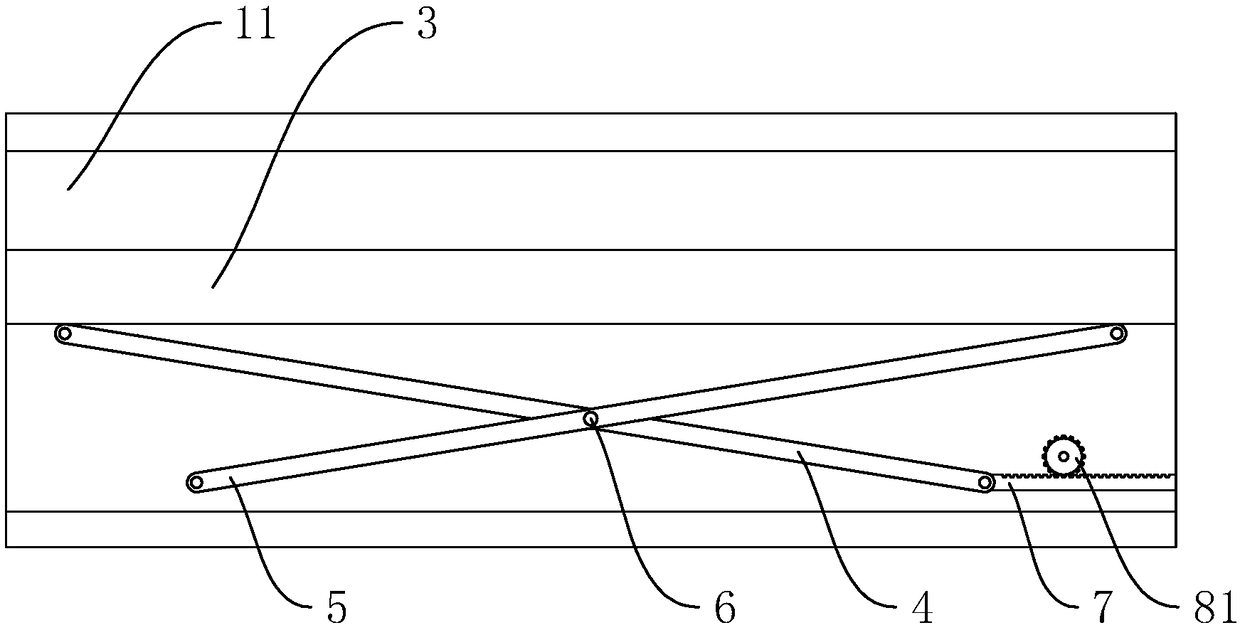

[0023] structured as Figure 2 to Figure 4 As shown, the bottom of the wiring trough 11 is provided with a supporting plate 3 for placing cables. The supporting plate 3 and the cover plate 2 are arranged horizontally, and the length of the supporting plate 3 is set to be equal to the length of the wiring trough 11. The length of the supporting plate 3 The lower side is provided with a first bracket 4 and a second bracket 5 that intersect each other. The first bracket 4 and the second bracket 5 are respectively hinged below the sides of the two ends of the length direction of the supporting plate 3. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com