Rotor of an inner rotor motor

An inner rotor motor and rotor technology, which is applied to the rotor field of inner rotor motors, can solve the problems of loss of adhesion effect, deterioration and aging of adhesives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

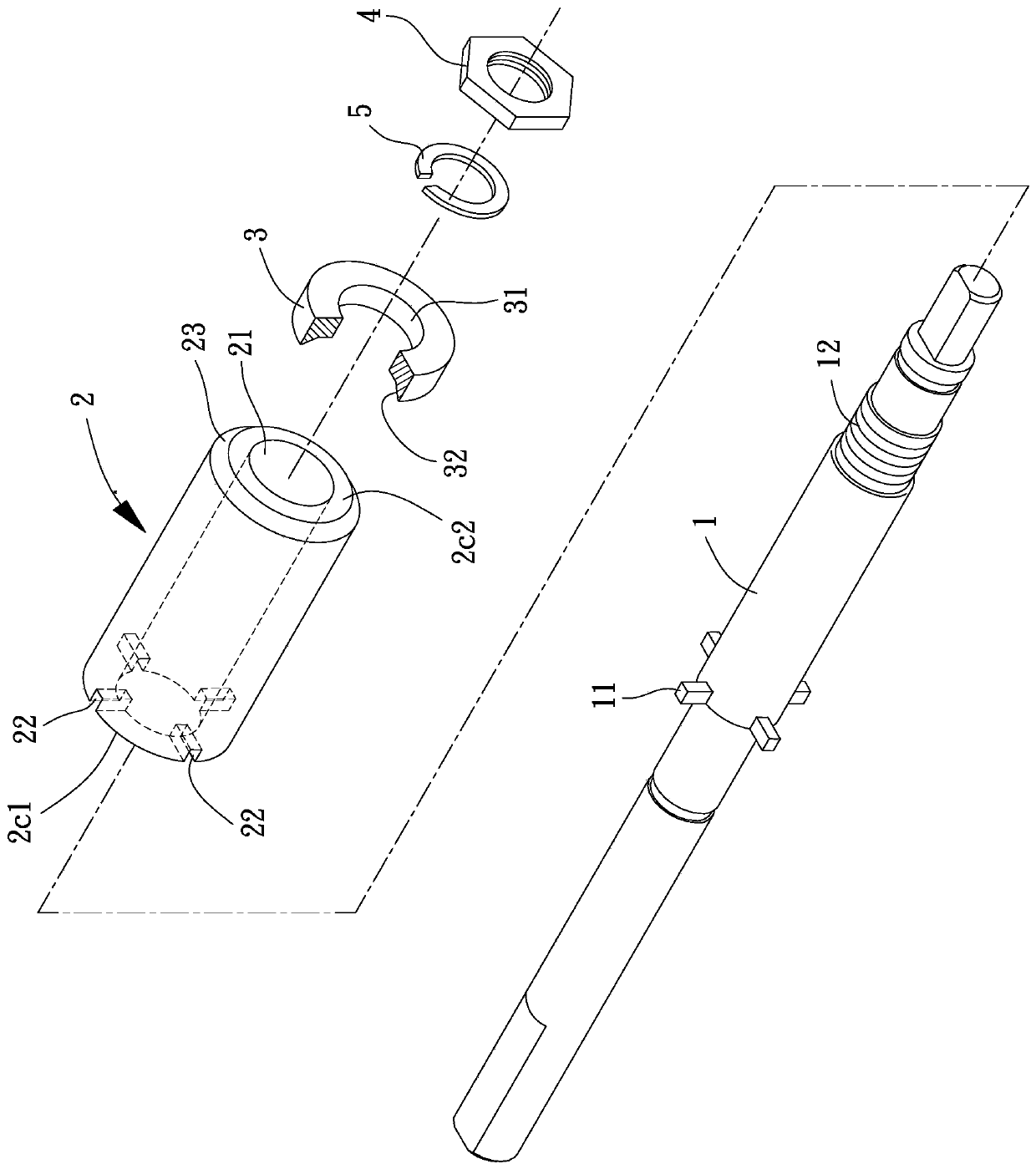

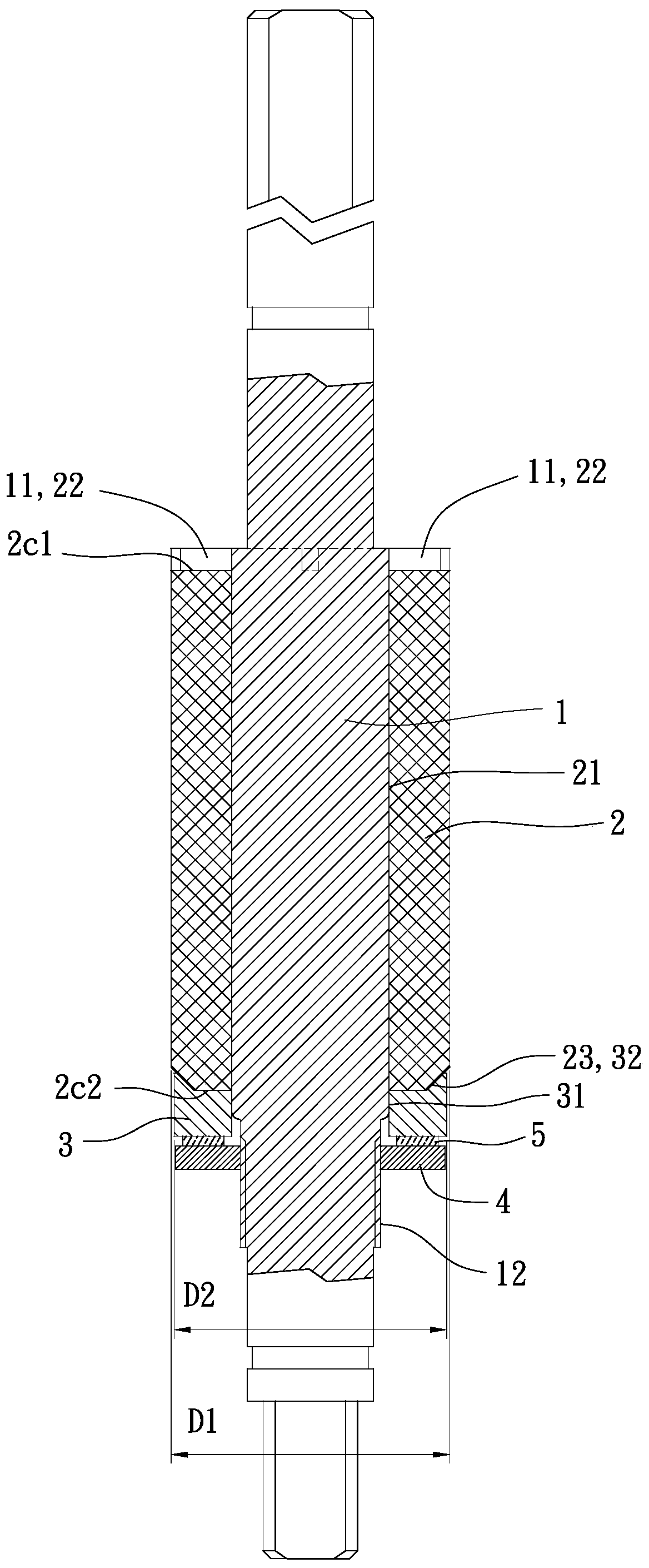

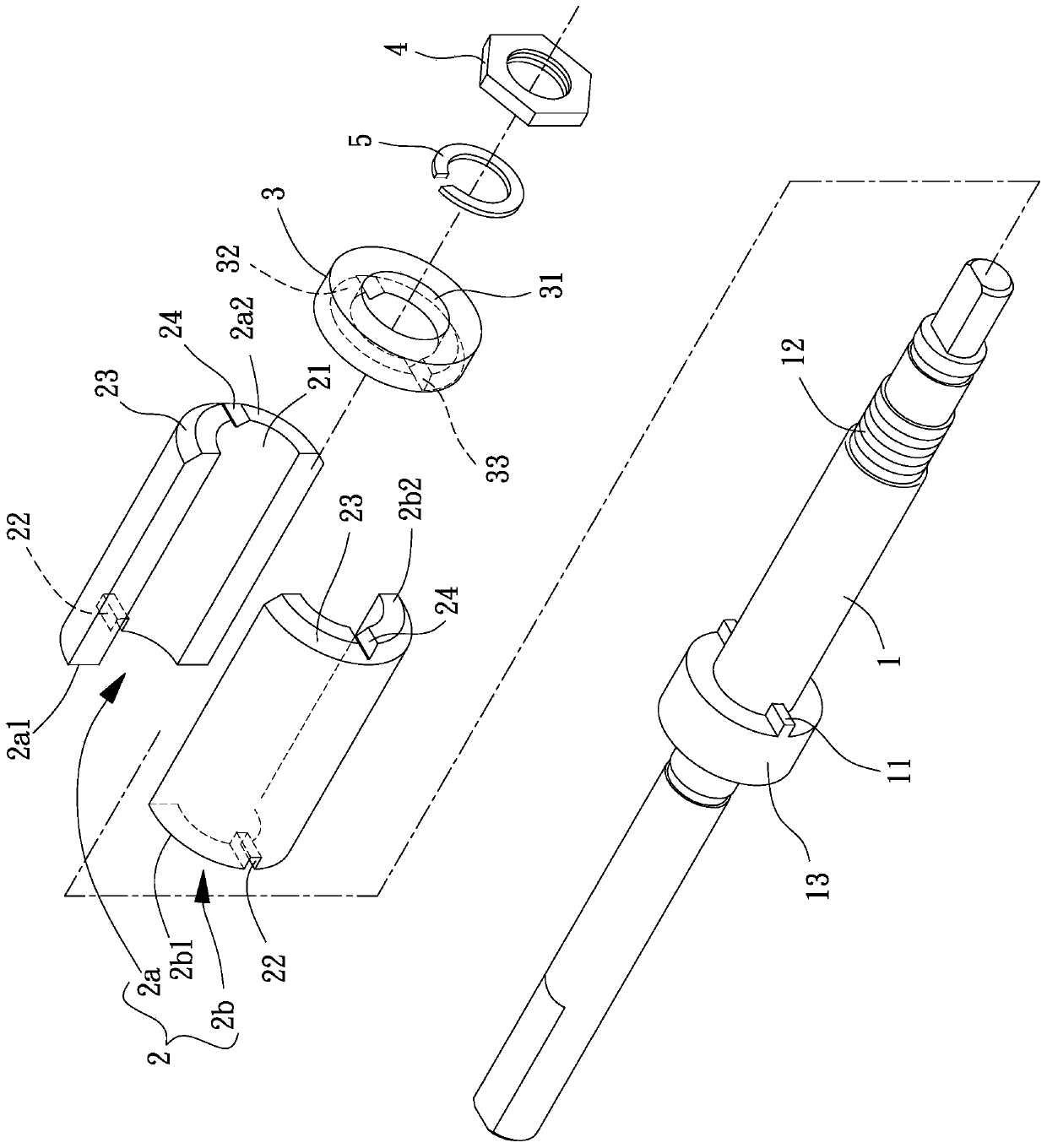

[0056] Please refer to figure 1 , which is the first embodiment of the rotor of the inner rotor motor of the present invention, the rotor of the inner rotor motor includes a rotating shaft 1, a permanent magnet 2 and a set of connectors 3, the permanent magnet 2 is arranged on the outer periphery of the rotating shaft 1 On the other hand, the assembly part 3 is sheathed on the rotating shaft 1 and combined with one end of the permanent magnet 2 .

[0057] Please refer to figure 1 , 2, the rotating shaft 1 has at least one first positioning portion 11 and one second positioning portion 12, the at least one first positioning portion 11 is on the outer peripheral surface of the rotating shaft 1, the rotating shaft 1 is combined with the permanent magnet 2 The position has a section in the radial direction, and the section is preferably circular. The at least one first positioning portion 11 can be designed to protrude from the outer peripheral surface of the rotating shaft 1. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com