Fuel hose

A fuel and hose technology, which is applied in the direction of hoses, pipes, pipes/pipe joints/fittings, etc., can solve the problems of increasing the thickness of the fluororesin layer, low permeability, expensive hoses, etc., and achieve improved chemical resistance , the effect of improving softness and improving affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Preparation of resin composition

[0069] PA6 (component A) and PA9T (component B) were blended in the ratio shown in Table 1 below, and kneaded at 300°C for 1 to 2 minutes using a twin-screw kneader (manufactured by JSW). Next, mix the elastomer (i) (component C) in the ratio shown in the table, and mix at 300°C for 2 to 3 minutes using a twin-screw kneader (manufactured by JSW Co., Ltd., TEX-α) to prepare a resin composition. things.

[0070] Production of hose

[0071] The above-mentioned resin composition was extrusion-molded into a tube shape, and a single-layer hose (inner diameter 12 mm) composed of only a tube-shaped resin layer (thickness 1.0 mm) was produced.

Embodiment 2~8, comparative example 1~3

[0073] Except having changed the compounding ratio of each component into the ratio shown in following Table 1, it carried out similarly to Example 1, and produced the resin composition. And except having used this resin composition, it carried out similarly to Example 1, and produced the hose.

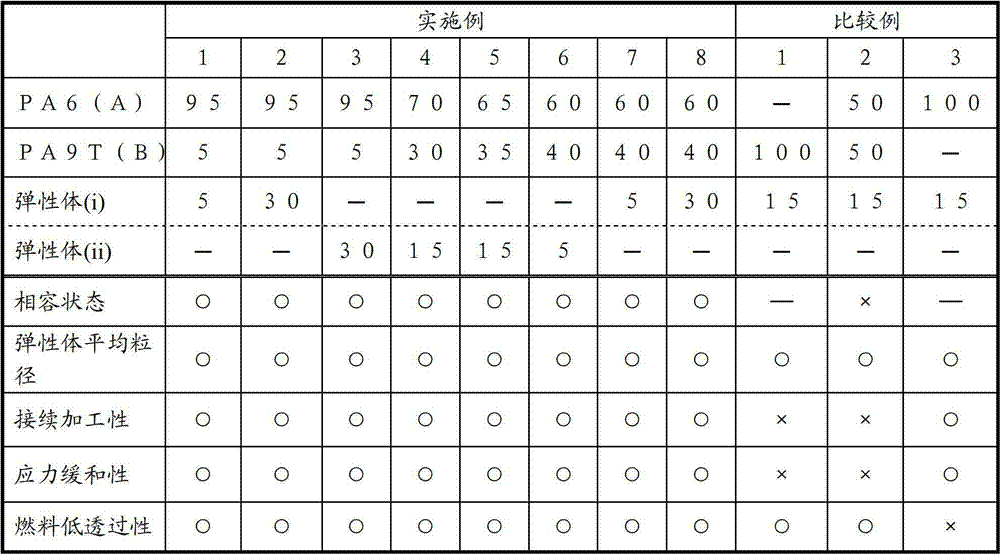

[0074] [Table 1] (parts by weight)

[0075]

[0076] The hoses of Examples and Comparative Examples obtained in this way were evaluated for each property based on the following criteria. The results are shown together in Table 1 above.

[0077] compatible state

[0078] Regarding the resin composition of each hose, the compatibility state of the aliphatic polyamide (component A) and the semiaromatic polyamide (component B) was confirmed. That is, the resin composition was thermally analyzed using DSC (manufactured by Shimadzu Corporation, DSC-60). The case where the endothermic peak attributable to the melting point was a single peak was evaluated as ◯ (compatible), and the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com