Electric scraper device for sintering cylinder mixer

A cylinder mixing and scraper device technology, which is applied in the field of metallurgical equipment and scraping equipment, can solve the problems of increasing the operating load of the cylinder mixer, threatening the personal safety of workers, reducing the production output of the cylinder mixer, and improving the operation of the equipment. Reliability, simplification of transmission system structure, and high promotion and use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following examples are only used to explain the present invention, so as to understand the implementation process of the present invention, and do not constitute a limitation to the protection scope of the present invention.

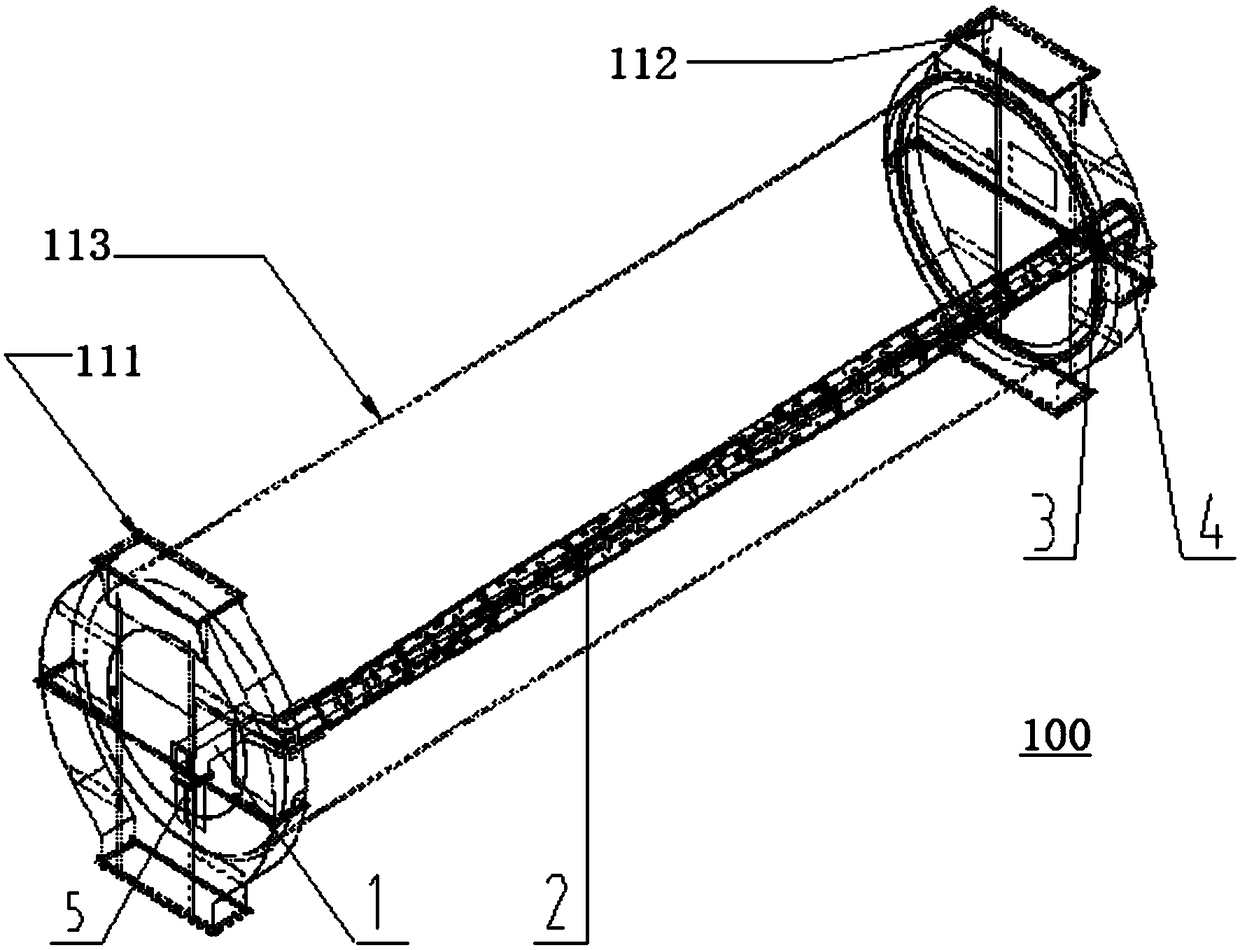

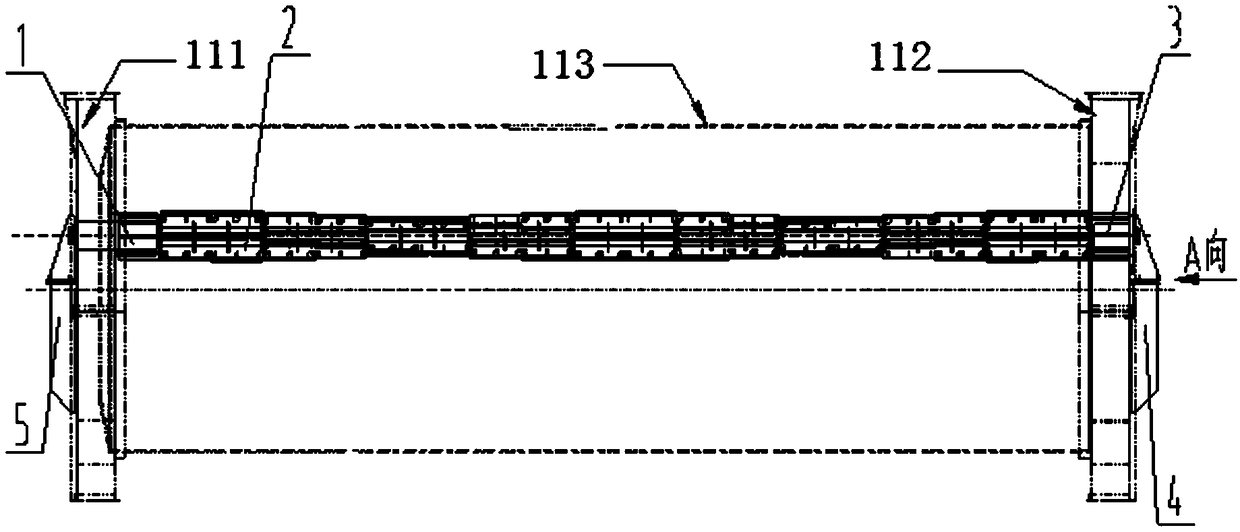

[0033] as attached figure 1 , attached figure 2 As shown, the electric scraper device 100 for the sintering cylinder mixer of the present invention includes a front transmission assembly 1, a cage scraper assembly 2 and a rear transmission assembly 3, wherein the electric cage scraper assembly 2 passes through the front transmission assembly 1 and the rear transmission assembly 3 The connecting flange is fixedly installed with the front support 5 and the rear support 4 of the drum mixer.

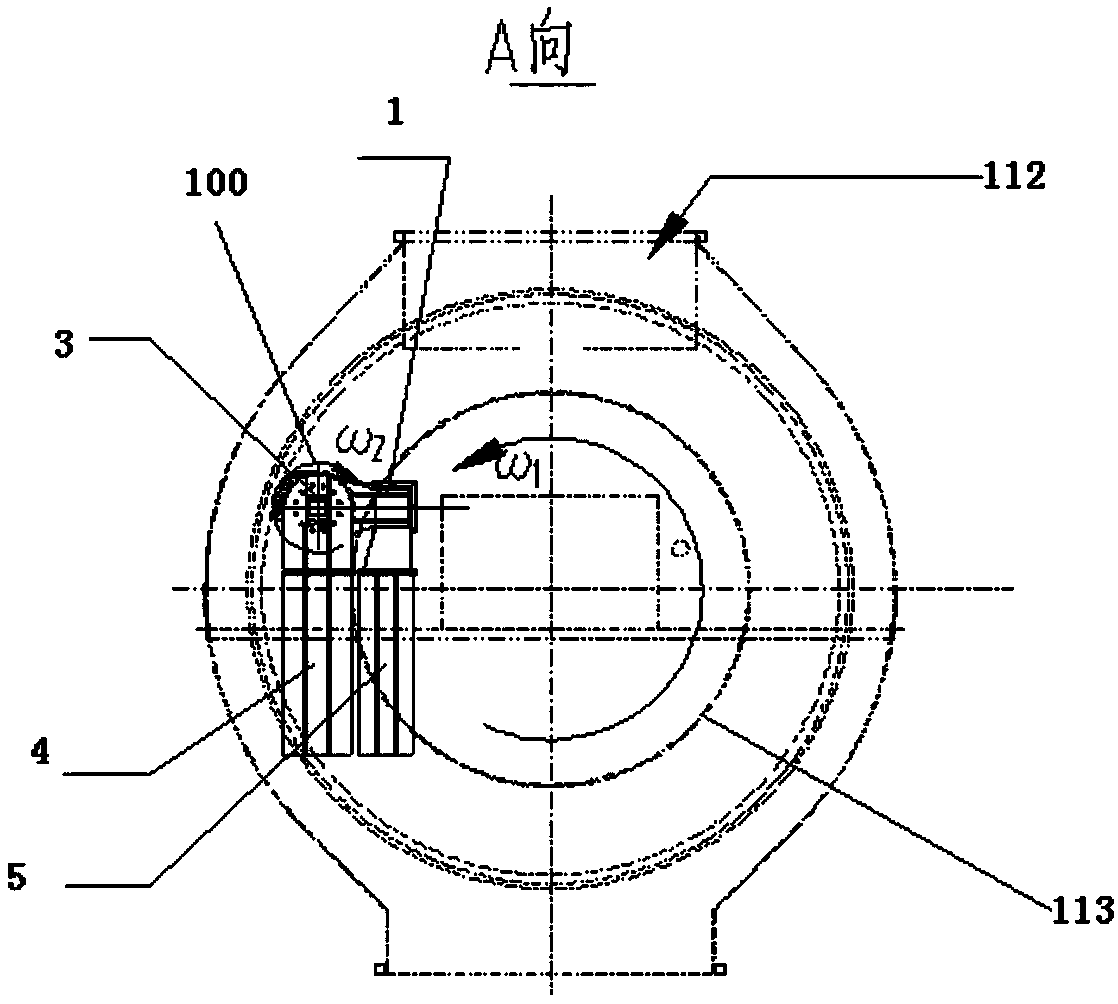

[0034] as attached image 3 As shown, the electric scraper device 100 for the sintering cylinder mixer of the present invention is installed on the opposite side of the material lifting of the cylinder mixer and is located near the horizontal center line ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com