Seed screening device convenient for replacing screen mesh

A screening device and seed technology, applied in seed and rhizome treatment, screening, solid separation, etc., can solve the problems of increasing labor intensity and reducing seed screening efficiency, and achieve the effects of reducing labor intensity, facilitating replacement, and improving screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

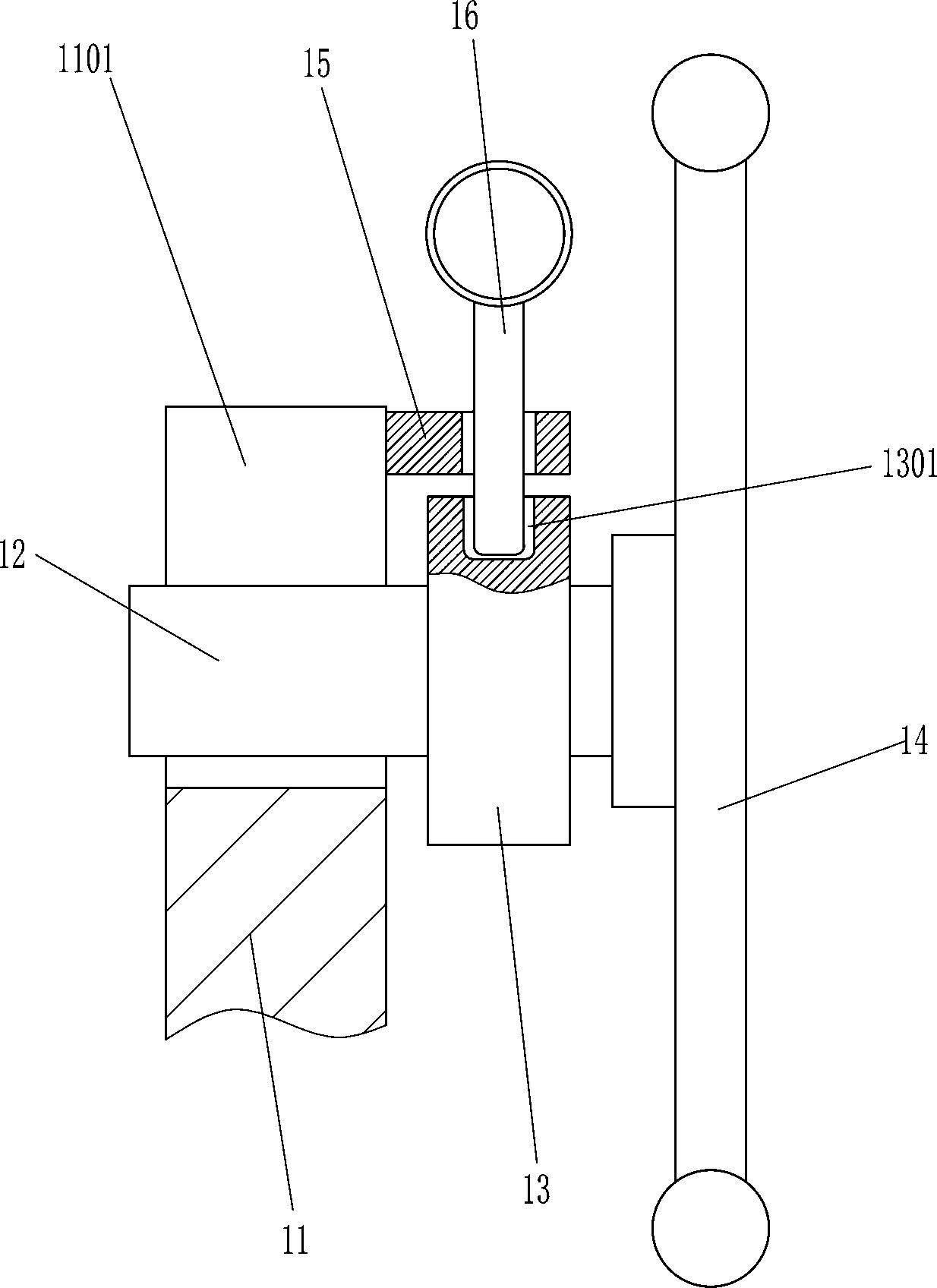

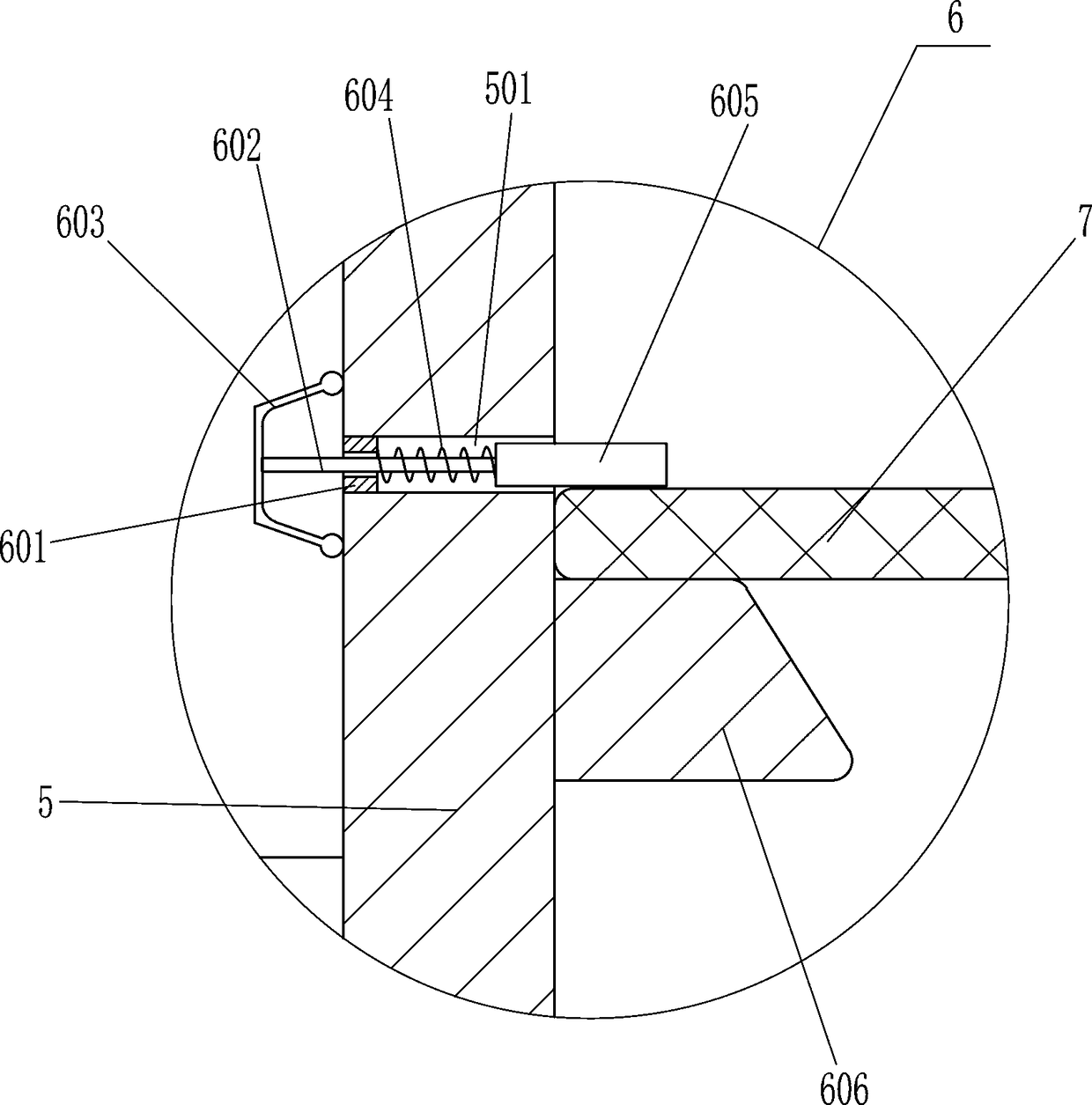

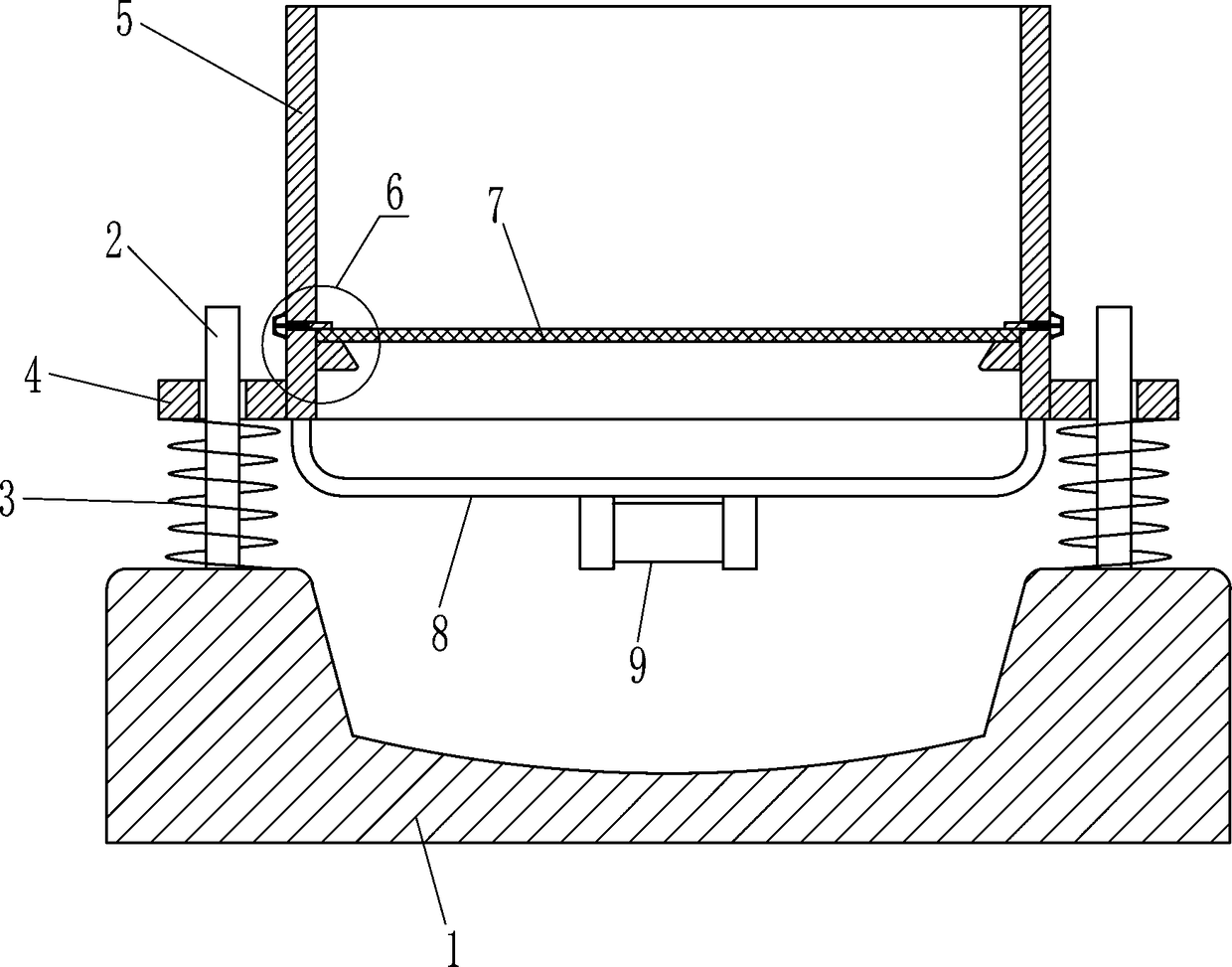

[0024] A seed screening device for easy replacement of the screen, such as Figure 1-4 As shown, it includes a first base 1, a first guide rod 2, a first spring 3, a guide sleeve 4, a screening frame 5, a clamping device 6, a screen 7, a U-shaped bracket 8 and a vibration motor 9, and the first guide There are two rods 2, which are respectively fixedly installed on the left and right sides of the top of the first base 1. The first guide rod 2 is provided with a sliding guide sleeve 4, and the first guide rod 2 is covered with a first spring for buffering. 3. The bottom end of the first spring 3 is connected to the top of the first base 1, the top of the first spring 3 is connected to the bottom of the guide sleeve 4, and a screening frame 5 is fixedly connected between the left and right guide sleeves 4, and the screening frame 5 The lower parts of the left and right sides are all provided with through holes 501, and a clamping device 6 is installed in the through holes 501. A...

Embodiment 2

[0026] A seed screening device for easy replacement of the screen, such as Figure 1-4As shown, it includes a first base 1, a first guide rod 2, a first spring 3, a guide sleeve 4, a screening frame 5, a clamping device 6, a screen 7, a U-shaped bracket 8 and a vibration motor 9, and the first guide There are two rods 2, which are respectively fixedly installed on the left and right sides of the top of the first base 1. The first guide rod 2 is provided with a sliding guide sleeve 4, and the first guide rod 2 is covered with a first spring for buffering. 3. The bottom end of the first spring 3 is connected to the top of the first base 1, the top of the first spring 3 is connected to the bottom of the guide sleeve 4, and a screening frame 5 is fixedly connected between the left and right guide sleeves 4, and the screening frame 5 The lower parts of the left and right sides are all provided with through holes 501, and a clamping device 6 is installed in the through holes 501. A ...

Embodiment 3

[0029] A seed screening device for easy replacement of the screen, such as Figure 1-4 As shown, it includes a first base 1, a first guide rod 2, a first spring 3, a guide sleeve 4, a screening frame 5, a clamping device 6, a screen 7, a U-shaped bracket 8 and a vibration motor 9, and the first guide There are two rods 2, which are respectively fixedly installed on the left and right sides of the top of the first base 1. The first guide rod 2 is provided with a sliding guide sleeve 4, and the first guide rod 2 is covered with a first spring for buffering. 3. The bottom end of the first spring 3 is connected to the top of the first base 1, the top of the first spring 3 is connected to the bottom of the guide sleeve 4, and a screening frame 5 is fixedly connected between the left and right guide sleeves 4, and the screening frame 5 The lower parts of the left and right sides are all provided with through holes 501, and a clamping device 6 is installed in the through holes 501. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com