Bidirectional deviation correction push rod with double input shafts

A technology with dual input shafts and push rods, applied in the directions of conveyors, transportation and packaging, can solve the problems of large application limitations, complex structure and high cost, and achieve the effect of reducing the frequency of failures and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

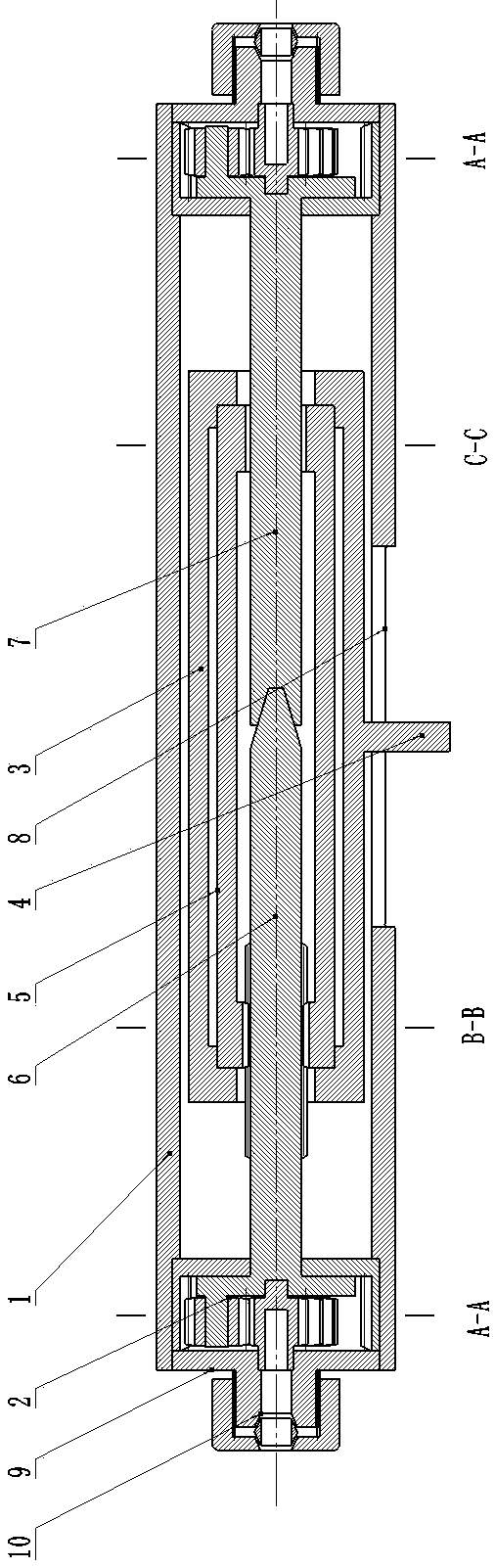

[0015] The dual-input-shaft bi-directional deflection correction push rod of the present invention will be described in detail below in conjunction with the accompanying drawings.

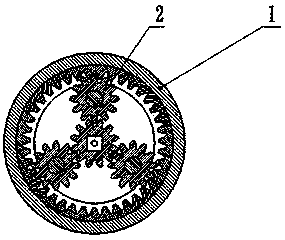

[0016] As shown in the figure, the present invention is a kind of flexible shaft transmission, through the alternate rotation and guidance of the screw shaft 6 and the screw sleeve 5, the double-input shaft bi-directional deviation correction push rod is realized, and its feature is: it consists of a shell 1 and a wheel inside the shell. Side reducer 2, push rod cover 3, screw cover 5, screw shaft 6 and hexagonal shaft 7 are composed of six major parts.

[0017] The housing 1 is a tubular housing, the middle part of the housing 1 is provided with a sliding groove 8 of the push rod arm, and the two ends are provided with end caps 9, and the outer ends of the end caps are provided with communication channels connected with the flexible shaft and the flexible shaft tube. Hole joint 10;

[0018] The w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com