Multi-path hydraulic system of hydraulic excavator

A technology of hydraulic excavators and hydraulic systems, which is applied in the direction of earthmoving machines/shovels, construction, etc., can solve the problems of inability to control independently, increase in control instability factors, and inability to realize energy-saving control, and avoid energy consumption. Wasteful, flexible control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

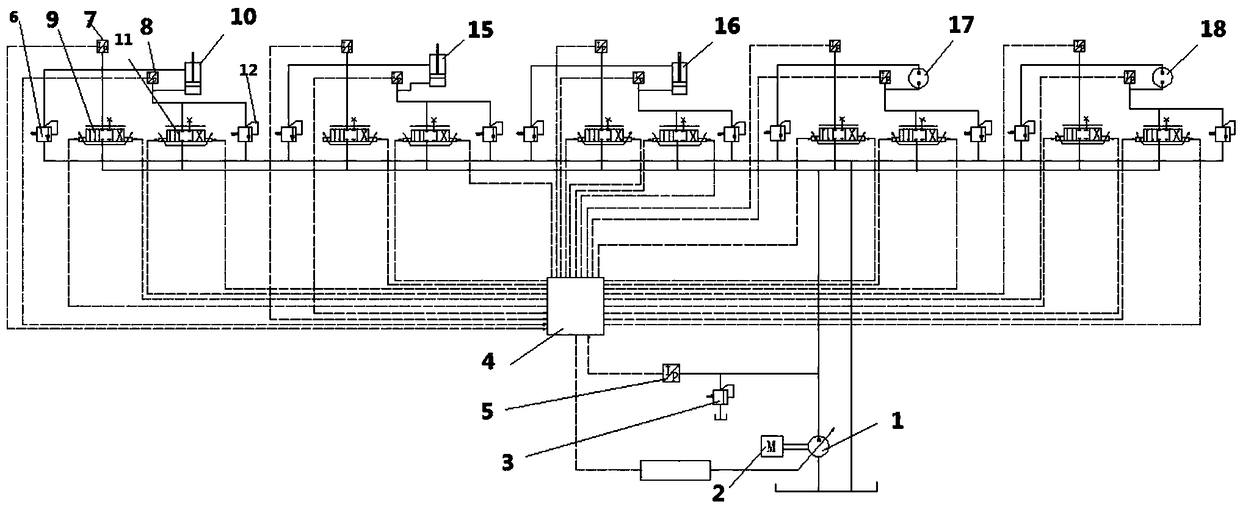

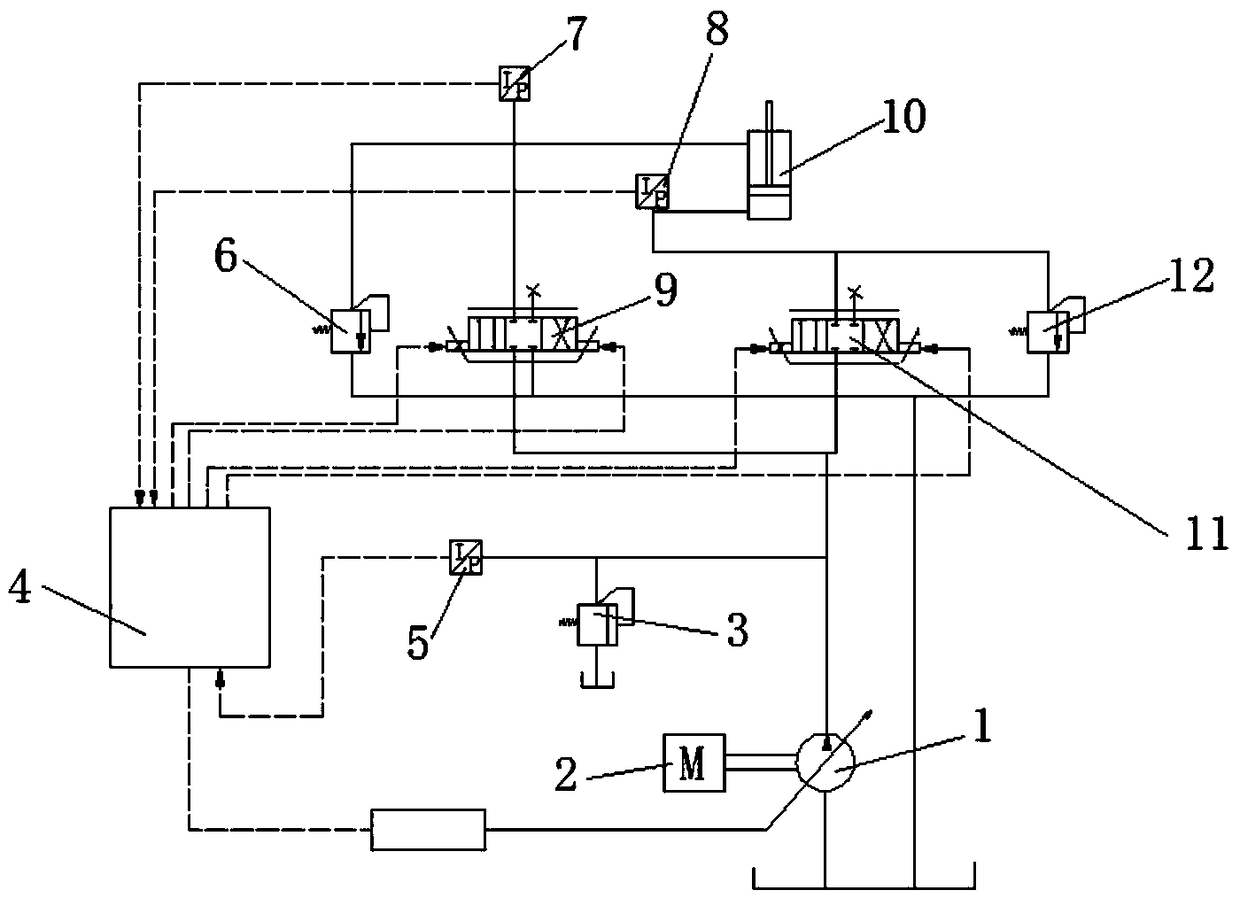

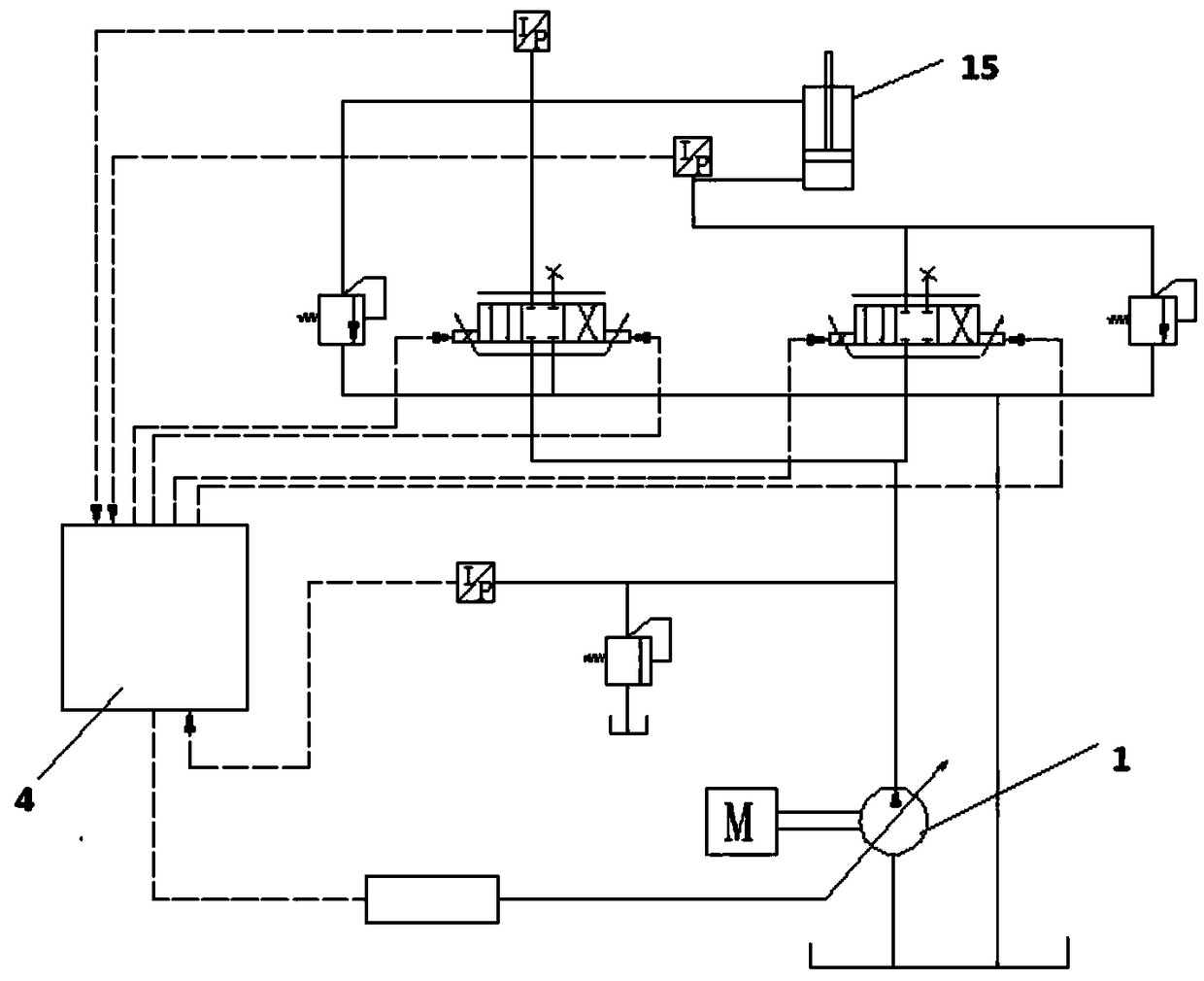

[0028] The present invention is further described below in conjunction with accompanying drawing:

[0029] see Figure 1 to Figure 6 , a hydraulic excavator multi-channel hydraulic system, including a controller 4, an oil inlet pipe, an oil return pipe, a variable pump 1, a boom cylinder hydraulic system, an arm cylinder hydraulic system, a bucket cylinder hydraulic system, a swing motor hydraulic system and a walking Motor hydraulic system; the outlet of the variable pump 1 is connected to the oil inlet pipe through the pipeline, and the inlet of the variable pump 1 is connected to the oil return pipe through the pipeline; the hydraulic system of the boom cylinder, the hydraulic system of the arm cylinder, the hydraulic system of the bucket cylinder, and the hydraulic system of the swing motor The hydraulic system of the travel motor and the travel motor are both arranged between the oil inlet pipe and the oil return pipe;

[0030] The hydraulic system of the boom cylinder i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com