Wall type viscous damper

A viscous damper and box technology, applied to walls, protective buildings/shelters, building components, etc., can solve the problems of large size, small output, and bubble generation, and achieve simple structure, stable output, and prevent The effect of deformation damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiments of the present invention will be further described below in conjunction with the drawings.

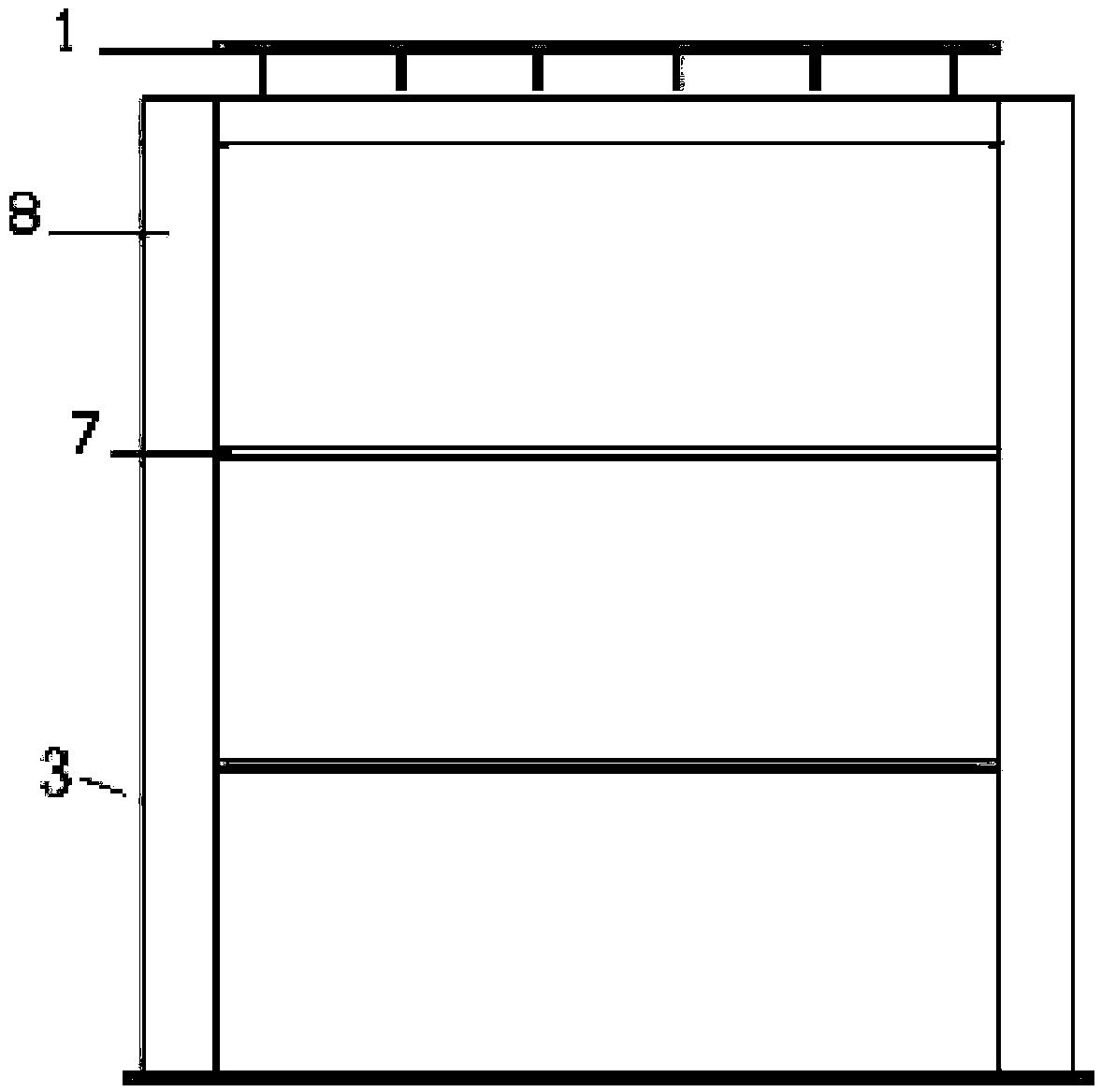

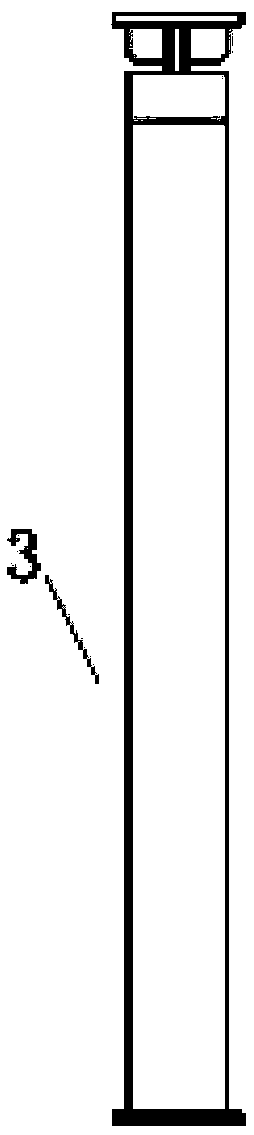

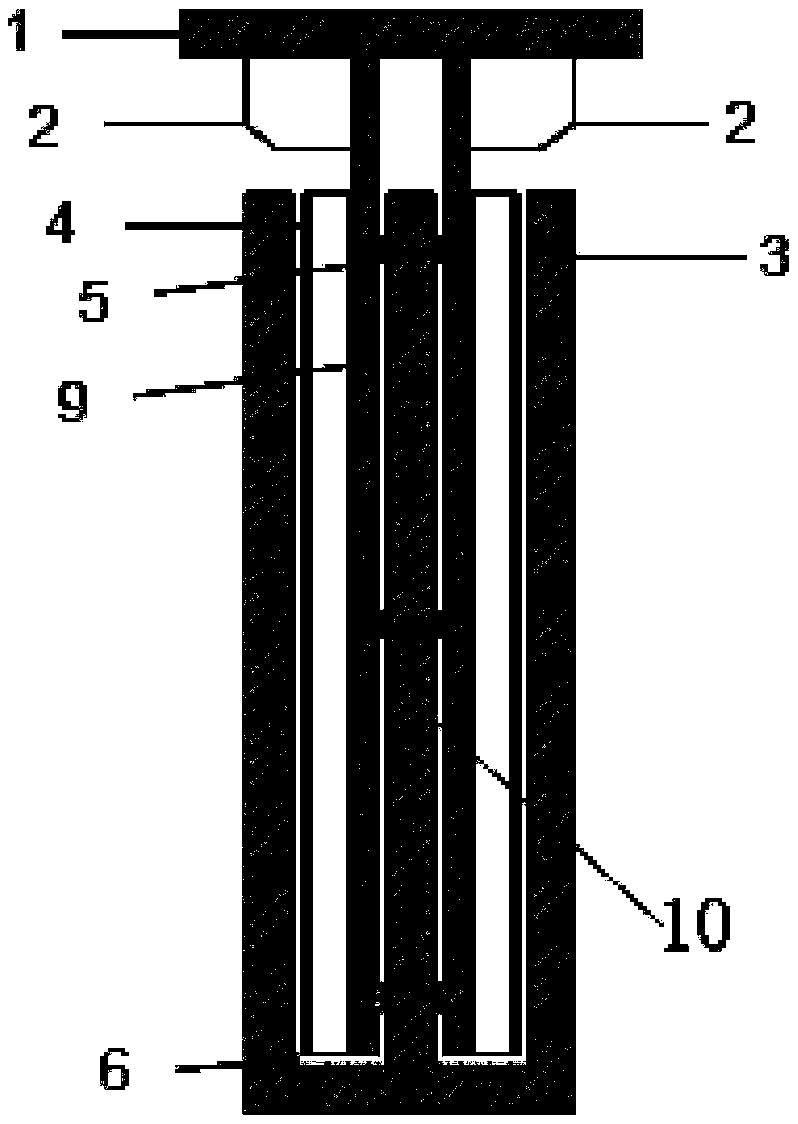

[0015] Figure 1~4 It includes upper connecting plate 1, first stiffener 2, box body 3, baffle 4, stop block 5, damping viscous liquid 6, second stiffener 7, liquid storage 8, shear steel plate 9, and partition 10 and so on.

[0016] Such as Figure 1~4 As shown, the present invention is a wall-type viscous damper, including a box body 3, the two ends of the box body 3 in the width direction are respectively provided with liquid storage 8, the liquid storage 8 is connected with the inner cavity of the box body 3, the box body 3 A damping viscous liquid 6 is set in the box body 3, and the partition 10 inside the box body 3 divides the box body into two communicating chambers; the bottom surface of the upper connecting plate 1 is fixedly provided with two shear steel plates 9 arranged parallel to each other. The shear steel plate 9 extends into the box body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com