Area outburst-prevention method through blasting, water-injection and fracturing integration gas displacement

A displacement and regional technology, applied in the direction of gas discharge, mining fluid, earth drilling, etc., can solve the problems of difficult to guarantee the effect of gas drainage and the small degree of development of coal seam fissures, and achieve wide practicability, improve drainage effect, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

[0024] A regional outburst prevention method for blasting, water injection and fracturing integrated gas displacement of the present invention, the specific steps are as follows:

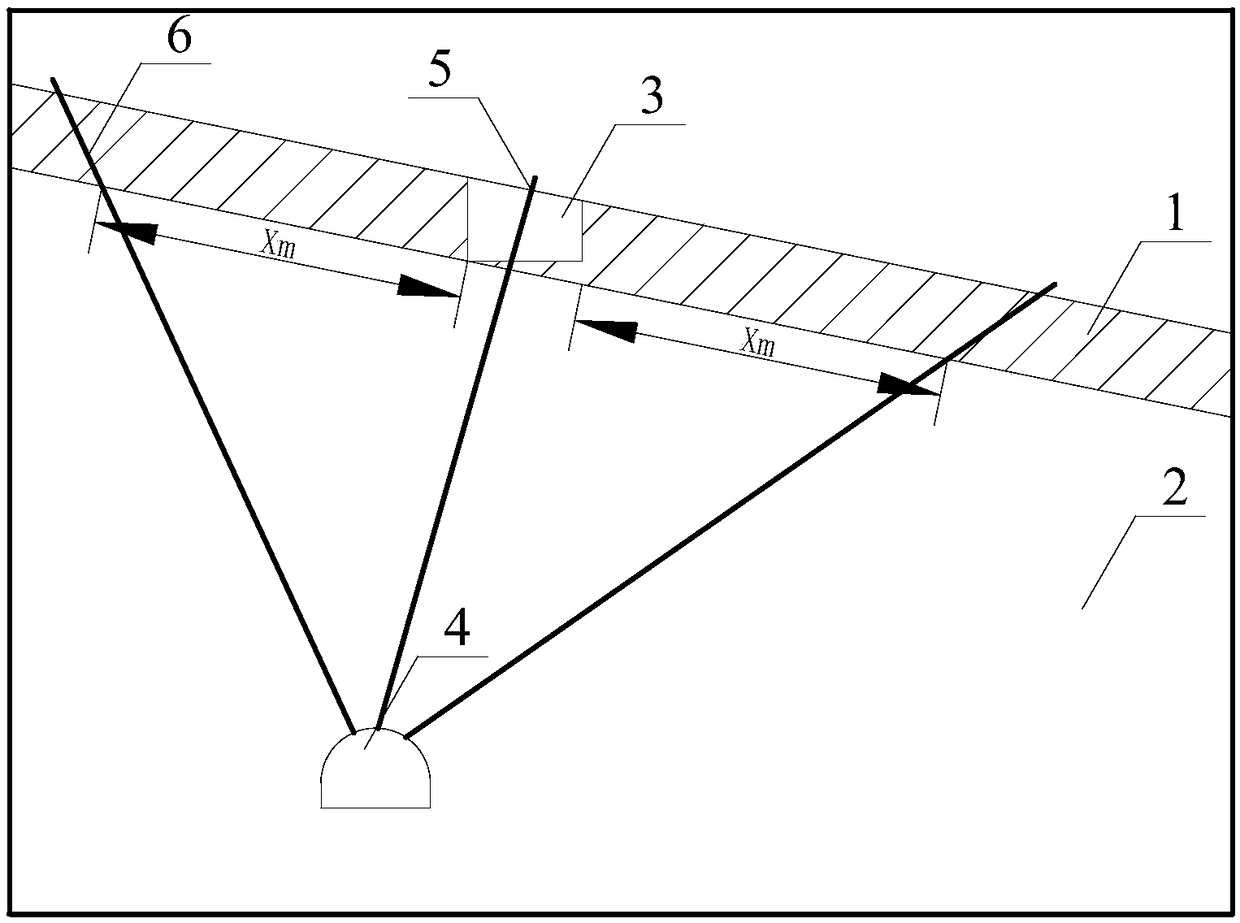

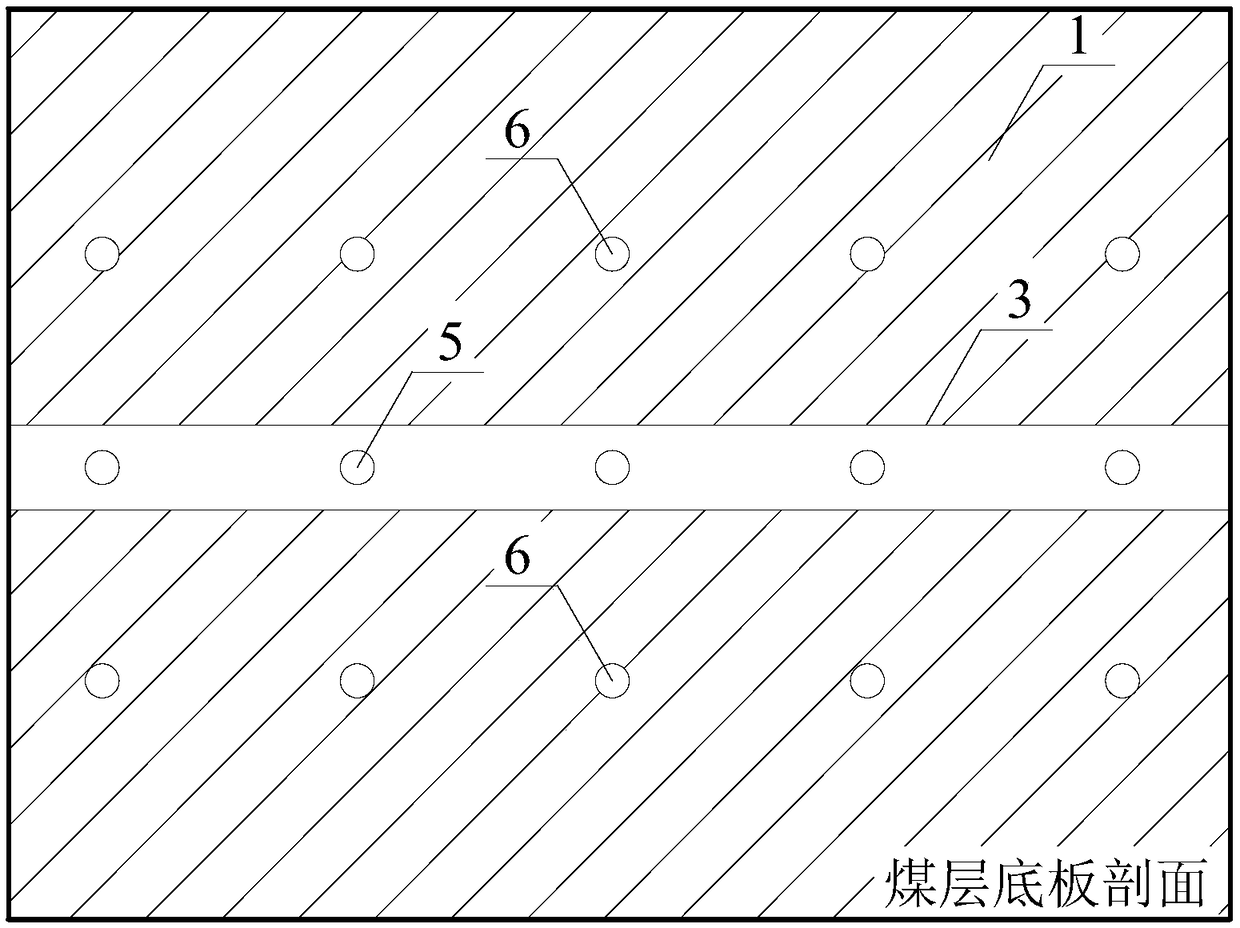

[0025] a. First determine the position of the pre-excavation roadway 3 in the coal seam 1, and then construct the auxiliary roadway 4 below or above the pre-excavation roadway 3;

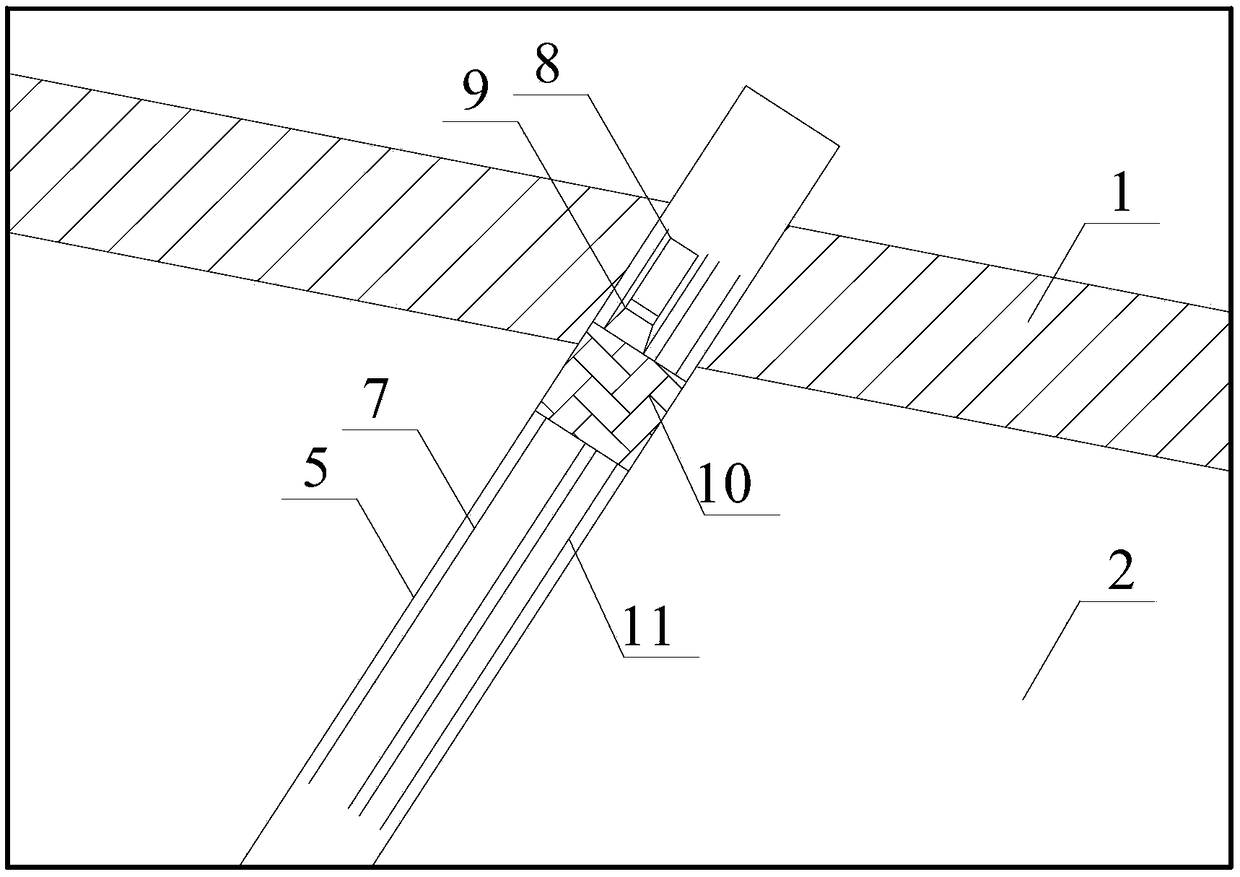

[0026] b. Construct a row of detonation holes 5 from the auxiliary roadway 4 into the pre-excavation roadway 3; then construct two rows of partition holes 6 from the auxiliary roadway 4 to the left and right sides of the pre-excavation roadway 3, and the detonation holes 5 are layer-penetrating Drilling, passing through the rock formation 2 and passing through the coal seam 1 is not less than 0.5m; the auxiliary roadway 4 is a roadway high pumping roadway or a bottom pumping roadway; the interval...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com