Gas-liquid two-phase alternating phase drive fracturing coal body enhanced gas drainage method in underground coal mine

A technology of gas drainage and fracturing, which is applied in the field of gas control in the underground area of coal mines. It can solve the difficulties of high-energy gas preparation, transportation and fracturing control, weaken the hydraulic fracturing and increase the permeability of coal bodies, and block the channels for gas gushing, etc. , to achieve the effect of improving the gas drainage effect, wide applicability, and promoting the development of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

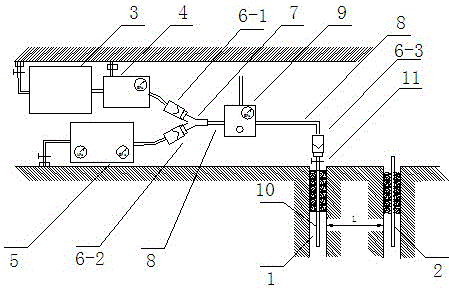

[0018] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0019] The gas-liquid two-phase alternating phase drive fracturing coal body enhanced gas drainage method in underground coal mines of the present invention:

[0020] a. First, construct a borehole in the coal seam or through the seam as the fracturing borehole 1, and construct a borehole with the same parameters on the side away from the fracturing borehole 1 as the water guide hole 2, and the water guide hole 2 and the fracturing borehole The distance L of 1 is 2-4m, and the fracturing pipe 10 is installed according to the conventional technology, and the two boreholes are sealed with high pressure;

[0021] b. Connect fracturing equipment at the opening of fracturing borehole 1, and check the performance of hydraulic fracturing equipment and gas fracturing equipment. The supercharger 5, the water outlet pipe of the water supply device and the air outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com