Automatic lamp-tube light-source-strip attaching device and method

A technology for light source strips and light tubes, which is applied to light sources, lighting devices, semiconductor devices of light-emitting elements, etc., can solve the problems of low production efficiency, inability to mass production, low efficiency of manual sticking, etc., and achieves solutions to low efficiency and production efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

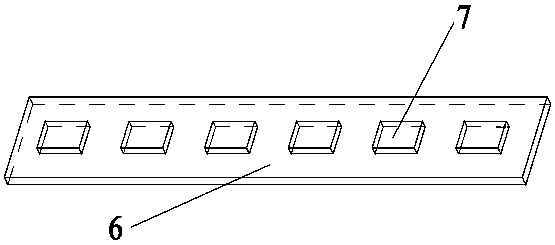

[0030] Such as figure 1 As shown, the light source bar includes an LED lamp bead 7 and an LED carrier 6. The LED carrier 6 can be a common circuit board, or a circuit board with a radiator installed, or an LED lamp directly mounted on a mirror surface metal. Bead 7 vector pattern. The LED lamp bead 7 communicates with the external power supply through the circuit on the carrier and the electrical connector.

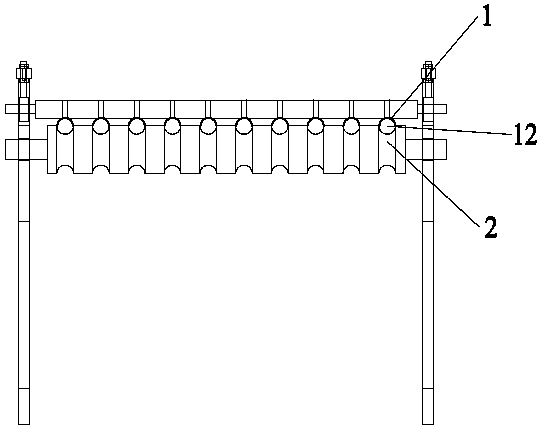

[0031] Such as figure 2 As shown, the curling mechanism includes several guide cylinders 1 and rollers 2, each of which is semi-cylindrical, and the rollers 2 are provided with several circles corresponding to each guide cylinder 1. Arc-shaped grooves, each of the guide cylinders 1 and the arc-shaped grooves on the corresponding rollers 2 form an arc-shaped cavity 12, the rollers 2 are connected with a driving device, and the elastic film passes through the arc-shaped grooves. When the arc-shaped cavity 12 is described, it forms a curl shape.

[0032] The first step ...

Embodiment 2

[0043] A method for automatically pasting strips of light source strips for lamp tubes, comprising using a device for automatically pasting strips for light source strips of light tubes as described in the above-mentioned embodiment 1 and a method for pasting strips, and the method of use includes the following steps:

[0044] Step 1. Set the lamp tube on the first limiting groove 53 in the fixed ferrule 51, and the movable ferrule 52 is driven by the power source to cooperate with the fixed ferrule 51 to form a The first circular limiting groove fixes the lamp tube, and at the same time forms the second circular limiting groove adapted to the shape of the elastic film and the light source bar component;

[0045] Step 2. Manually curl the flattened elastic film into a shape suitable for the arc-shaped cavity 12, and the roller 2 rolls under the action of the driving device to drive the subsequent flattened elastic film to continue to advance. The shaft 2 and the guide cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com