Six-dimensional force sensor

A six-dimensional force sensor and torque technology, applied in the field of sensors, can solve the problems of inability to concentrate strain gauges, low sensor sensitivity, and large coupling between dimensions, and achieve the effects of simple structure, avoiding mutual interference and improving dynamic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

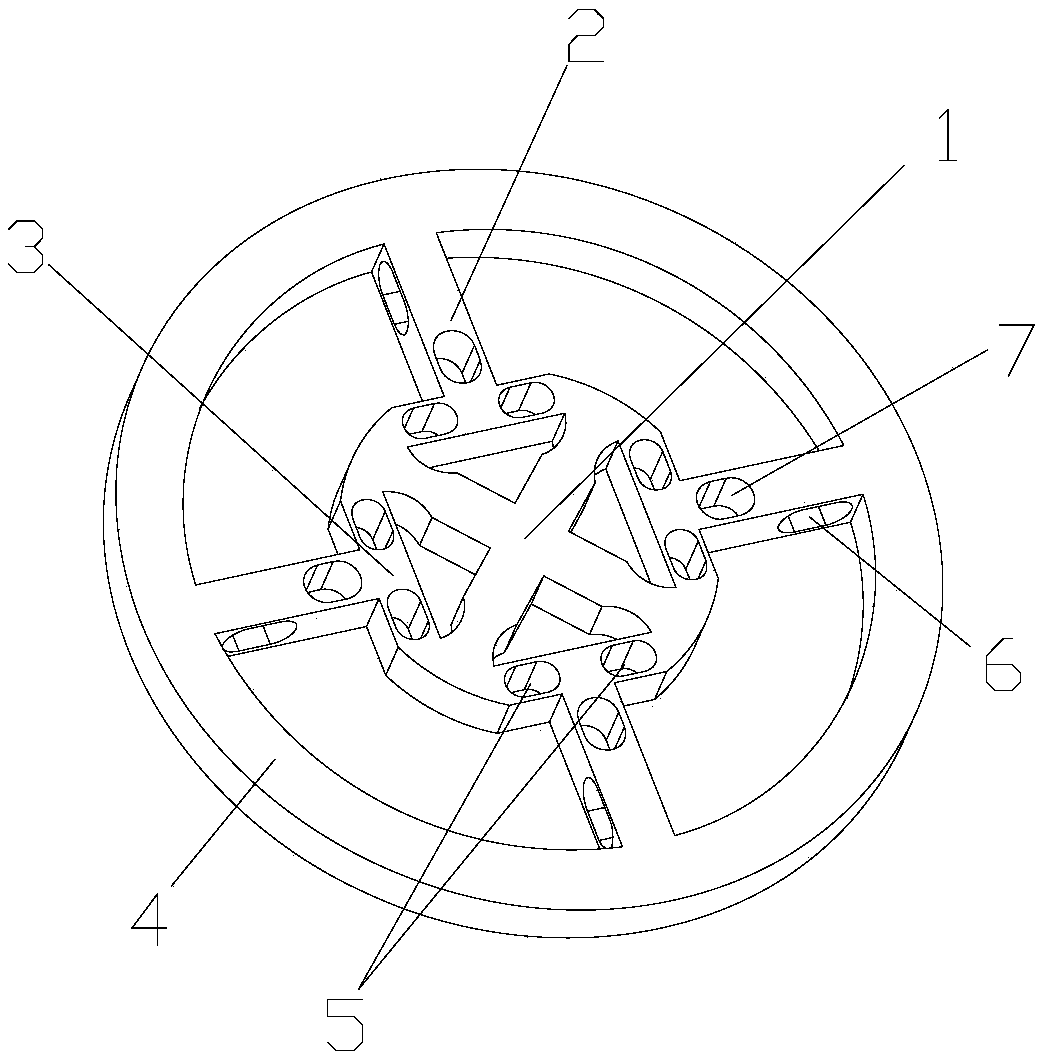

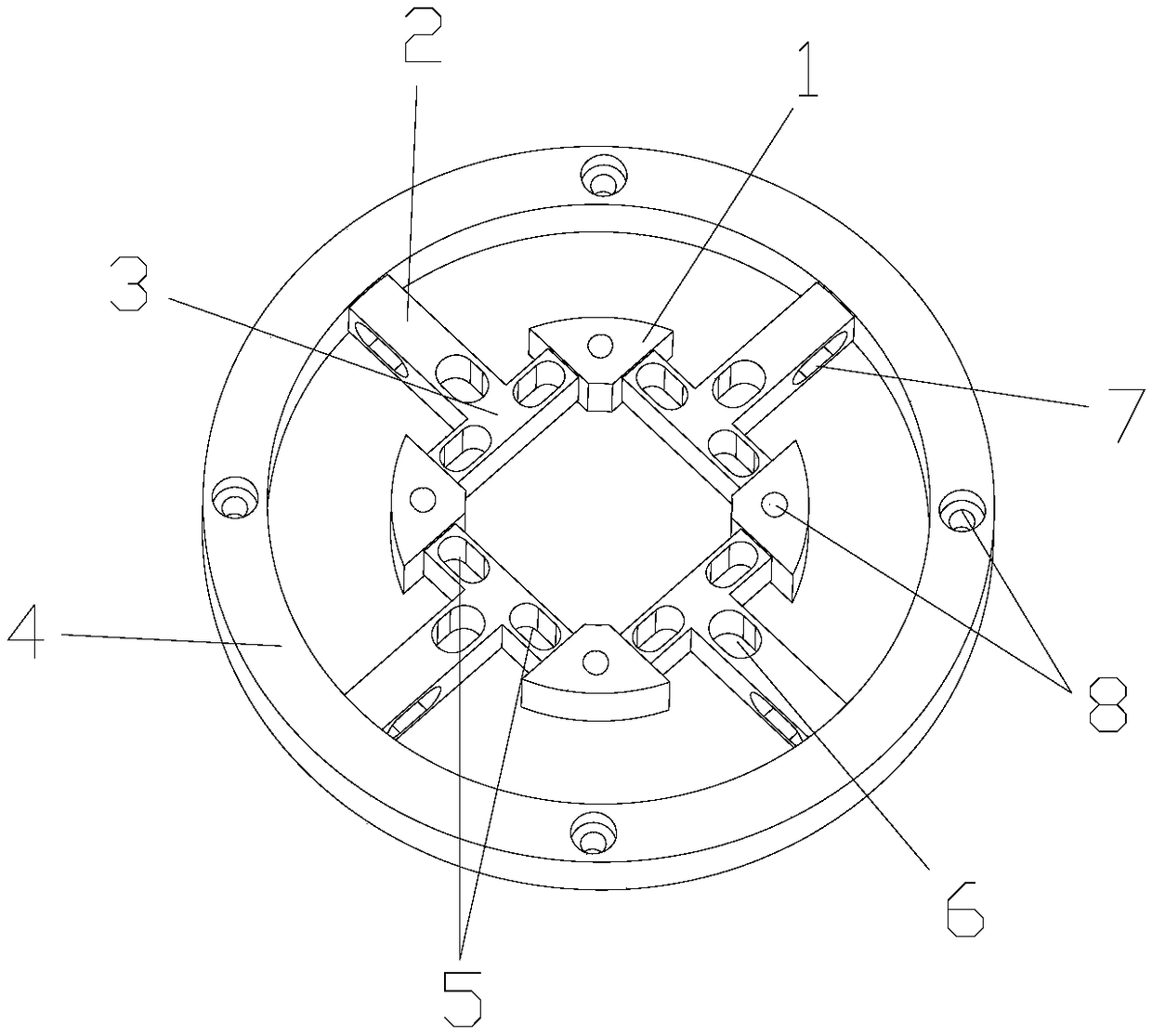

[0032] see figure 1 , Figure 1a and Figure 4 , the six-dimensional force sensor in this embodiment is: the center platform 1 is used as the inner ring, and the circumferential support 4 is used as the outer ring to form an inner and outer ring support structure; the inner end of the radial beam 2 is connected to the middle of the floating beam 3 to form a "T" beam structure; the radial beams 2 in the four sets of "T" beams are distributed in the shape of a "ten" on the periphery of the center platform 1, and the outer ends of each radial beam 2 are connected to the circumferential support 4. Two adjacent sections of floating beams 3 are connected by connecting blocks to form a ring-shaped central platform 1; for positioning and installation, positioning holes 8 are respectively provided on the circumferential support and each connecting block.

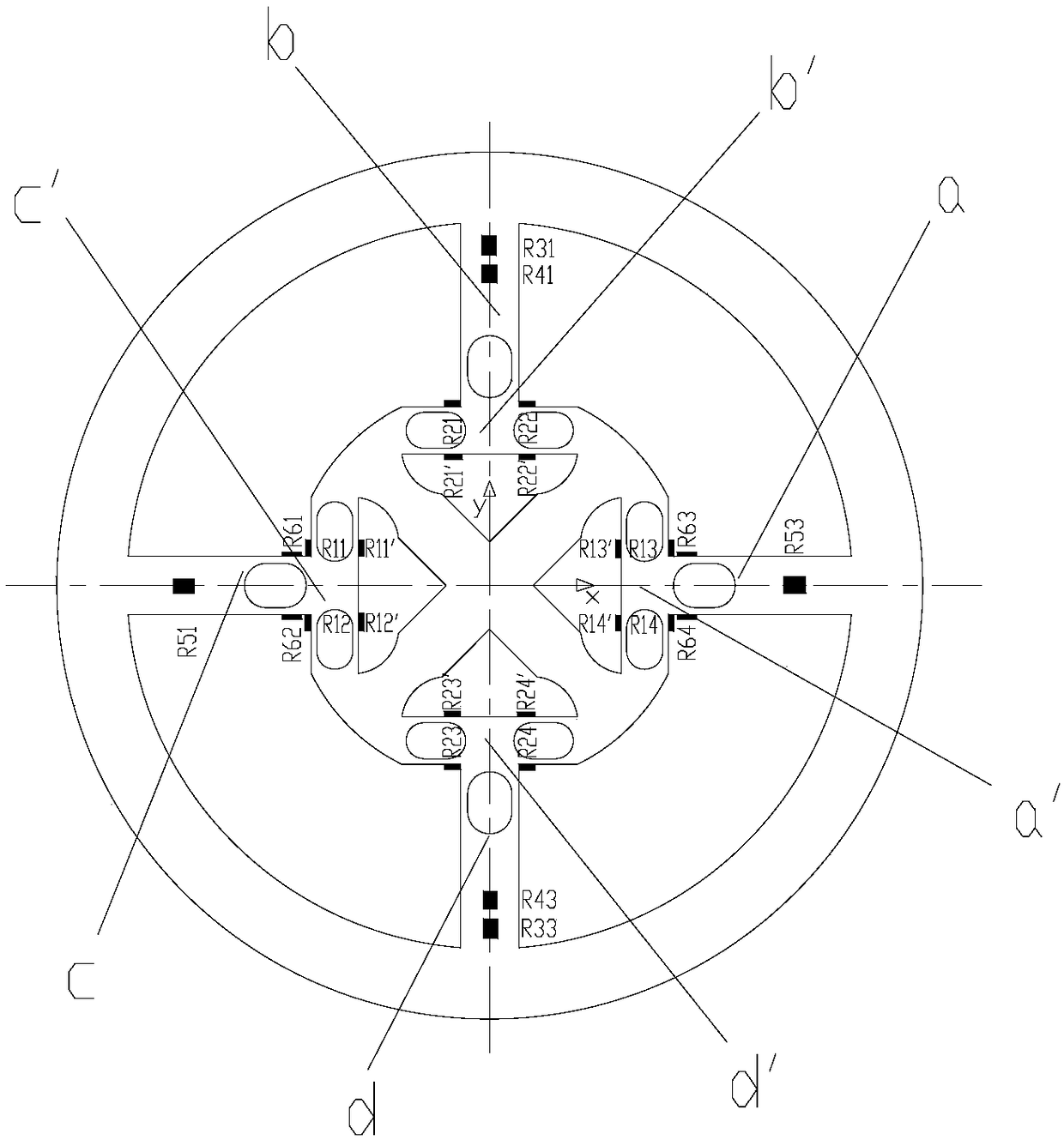

[0033] In this embodiment, the through holes and strain gauges are set on the radial beam 2 and the floating beam 3 in the follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com