A fatigue bearing design method of butt weld joint

A technique for welding joints, design methods, used in computing, special data processing applications, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

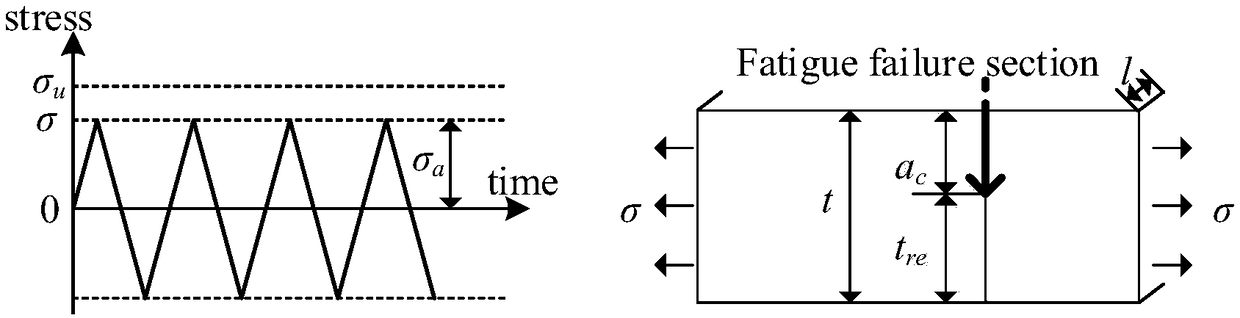

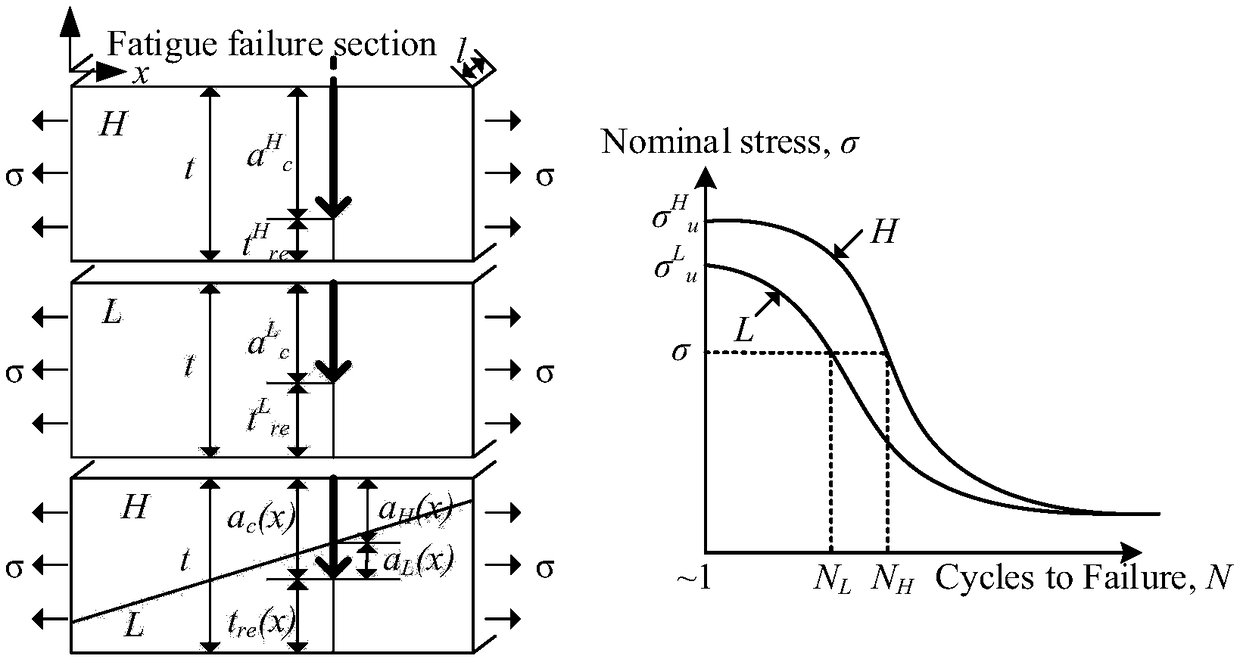

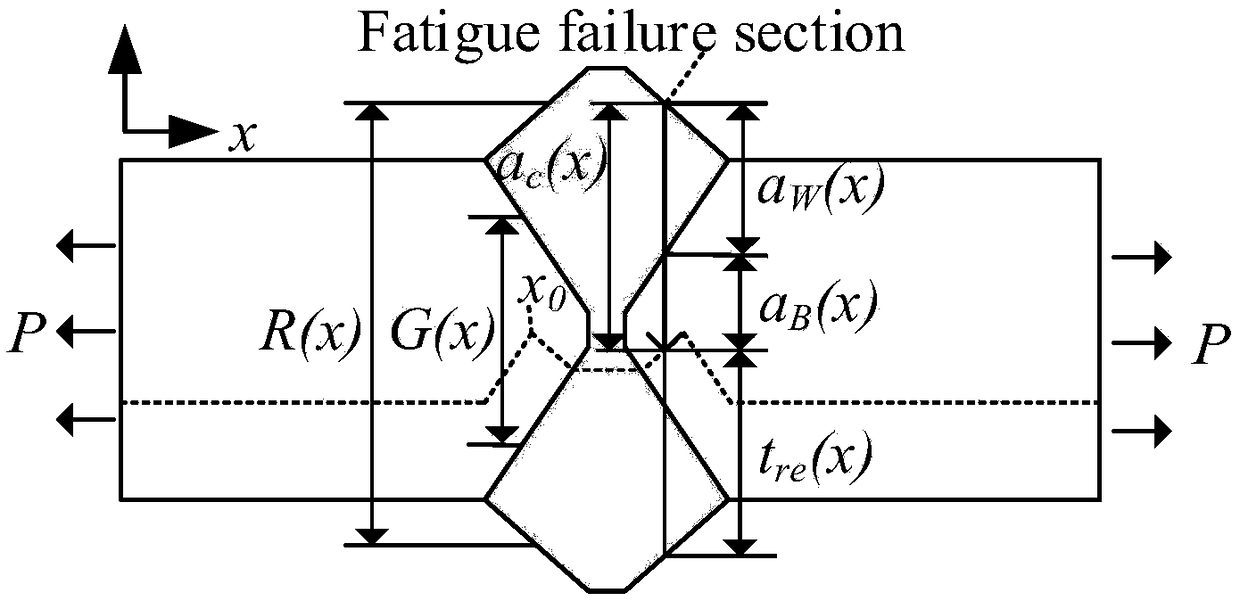

[0065] combine Figure 1-10 Describe in detail the implementation process of a fatigue load bearing design method for butt welded joints:

[0066] 1. According to the factors affecting the fatigue life of homogeneous materials and heterogeneous materials, it is possible to find a breakthrough where the welded joint and the base metal have a considerable fatigue bearing capacity. Since the fatigue life of homogeneous materials and heterogeneous materials is related to the stress distribution state, and the stress state of the material is determined by the geometric parameters, the stress state of the material can be affected by controlling the geometric parameters, thereby improving the fatigue bearing capacity of the material. In addition, different starting positions of fatigue cracks have no effect on the fatigue behavior of homogeneous materials, but affect the fatigue behavior of heterogeneous materials. Therefore, the proportion of each component material on different cra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com