Pixel circuit and driving method thereof, array substrate

A pixel circuit and drive unit technology, applied in the field of pixel circuits, can solve problems such as the maximum brightness limit of the display panel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

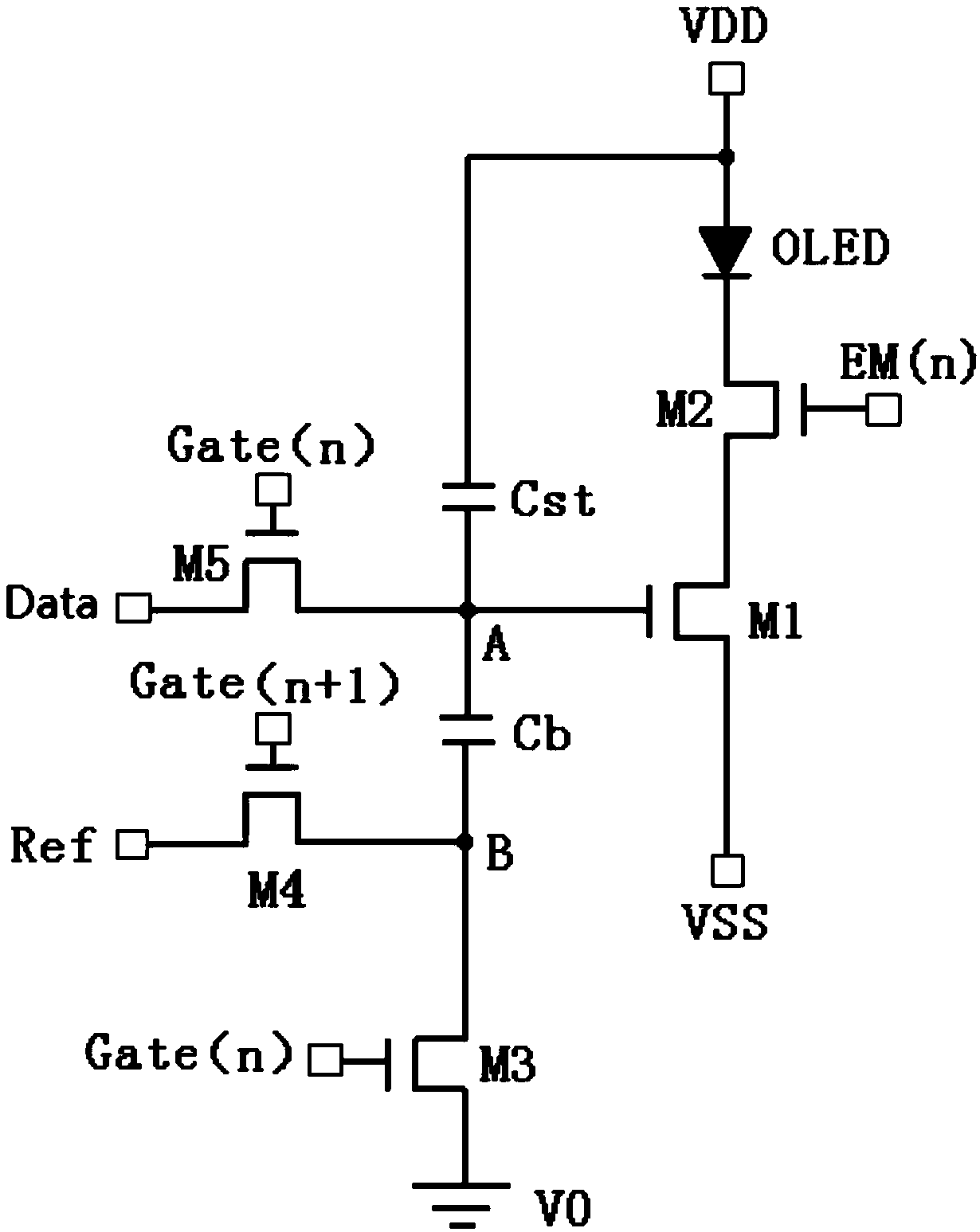

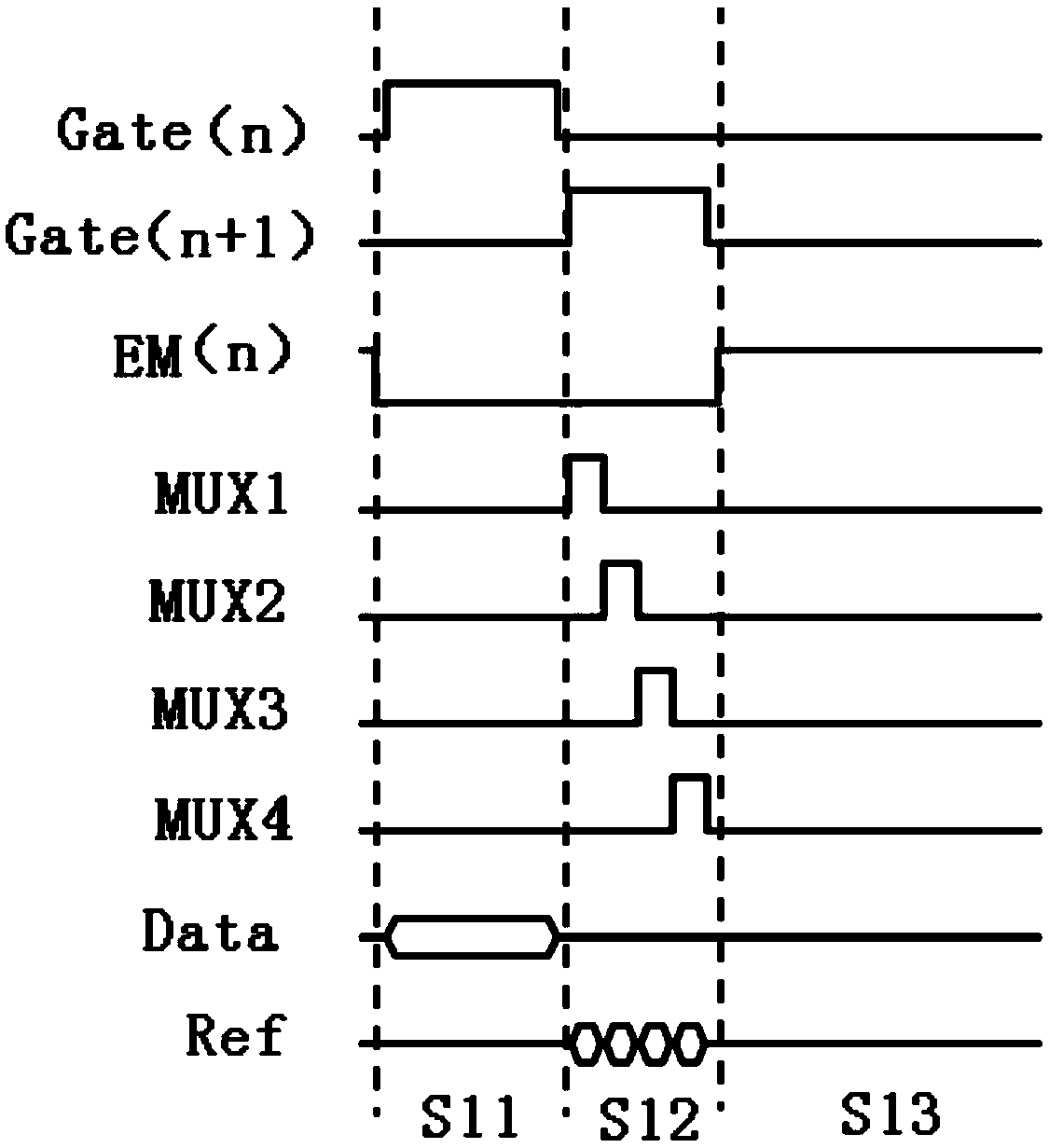

[0056] refer to Figure 1 to Figure 3 , this embodiment provides a pixel circuit.

[0057] The pixel circuit can emit light with different brightness, so it can be used in the pixels (also called sub-pixels) of the array substrate.

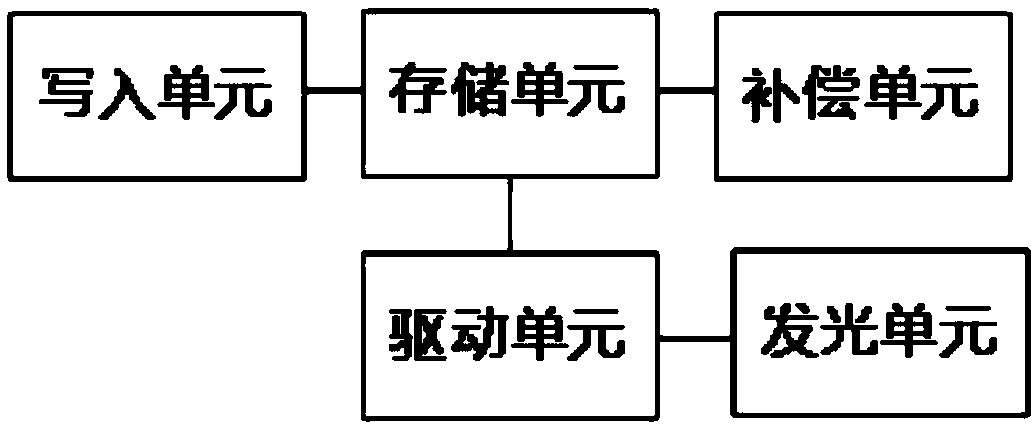

[0058] Specifically, refer to figure 1 , the pixel circuit includes:

[0059] a light emitting unit for emitting light;

[0060] The driving unit is used to drive the light emitting unit to emit light according to the driving voltage loaded on the driving unit;

[0061] a storage unit for storing the driving voltage applied to the driving unit;

[0062] a writing unit, for writing data voltage into the storage unit;

[0063] The compensation unit is used to write the compensation voltage into the storage unit, so as to obtain the driving voltage through the data voltage and the compensation voltage.

[0064]In the pixel circuit of the embodiment of the present invention, the writing unit can write the data voltage (for example, from the driv...

Embodiment 2

[0108] refer to Figure 4, this embodiment provides an array substrate, which particularly includes:

[0109] A plurality of pixel circuits 1 arranged in an array, where the pixel circuits 1 are any one of the above-mentioned pixel circuits 1 .

[0110] The array substrate includes a plurality of pixels (or sub-pixels) arranged in an array, and each pixel is provided with the above pixel circuit 1. Since the pixel circuit 1 may include an organic light emitting diode (OLED), the array substrate can be It is an organic light emitting diode array substrate.

[0111] Optionally, when the third transistor, the fourth transistor, and the fifth transistor in the pixel circuit 1 are all N-type transistors or all are P-type transistors, the array substrate further includes a plurality of data lines 4 and a plurality of gate lines 3; ,

[0112] The data voltage end of each column of pixel circuits 1 is connected to a data line 4;

[0113] The first gate voltage terminal of each row...

Embodiment 3

[0125] This embodiment provides a display panel, which includes any one of the above-mentioned display substrates.

[0126] That is to say, the above display substrate can be combined with the box substrate, driver chip, etc. to form a display panel with a display function. Wherein, when the display substrate is an OLED array substrate, the display panel is also an OLED display panel.

[0127] Specifically, the above display panel can be any product or component with a display function, such as electronic paper, mobile phone, tablet computer, television, monitor, notebook computer, digital photo frame, and navigator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com