A device and method for laser lift-off mass transfer of micro-device based on winding process

一种激光剥离、转移装置的技术,应用在半导体器件、半导体/固态器件制造、电气元件等方向,能够解决无法满足Micro-LED显示屏微器件巨量转移、效率低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention. In addition, the technical features involved in the various embodiments of the present invention described below may be combined with each other as long as they do not constitute a conflict with each other.

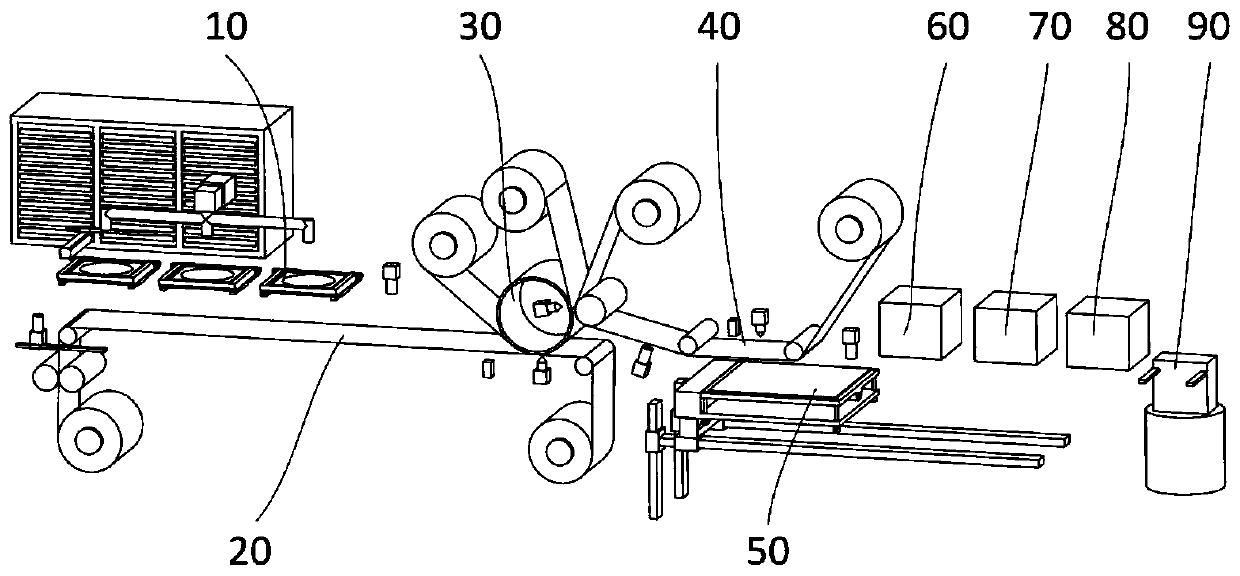

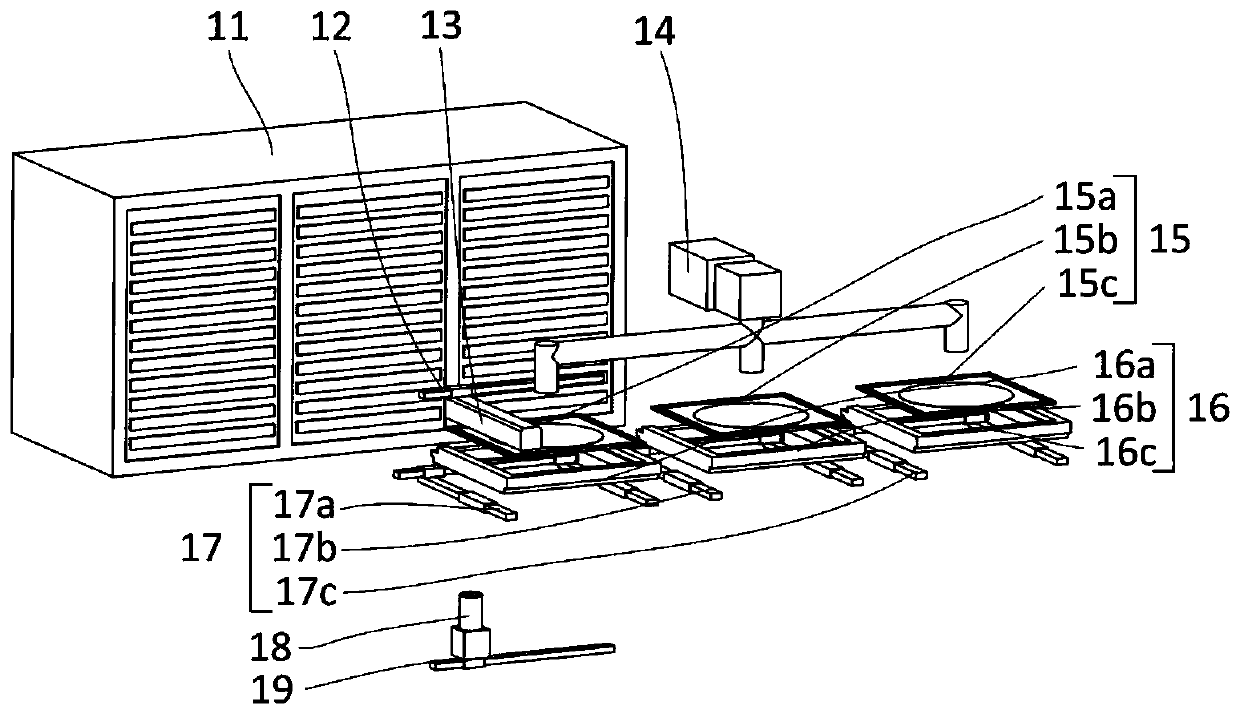

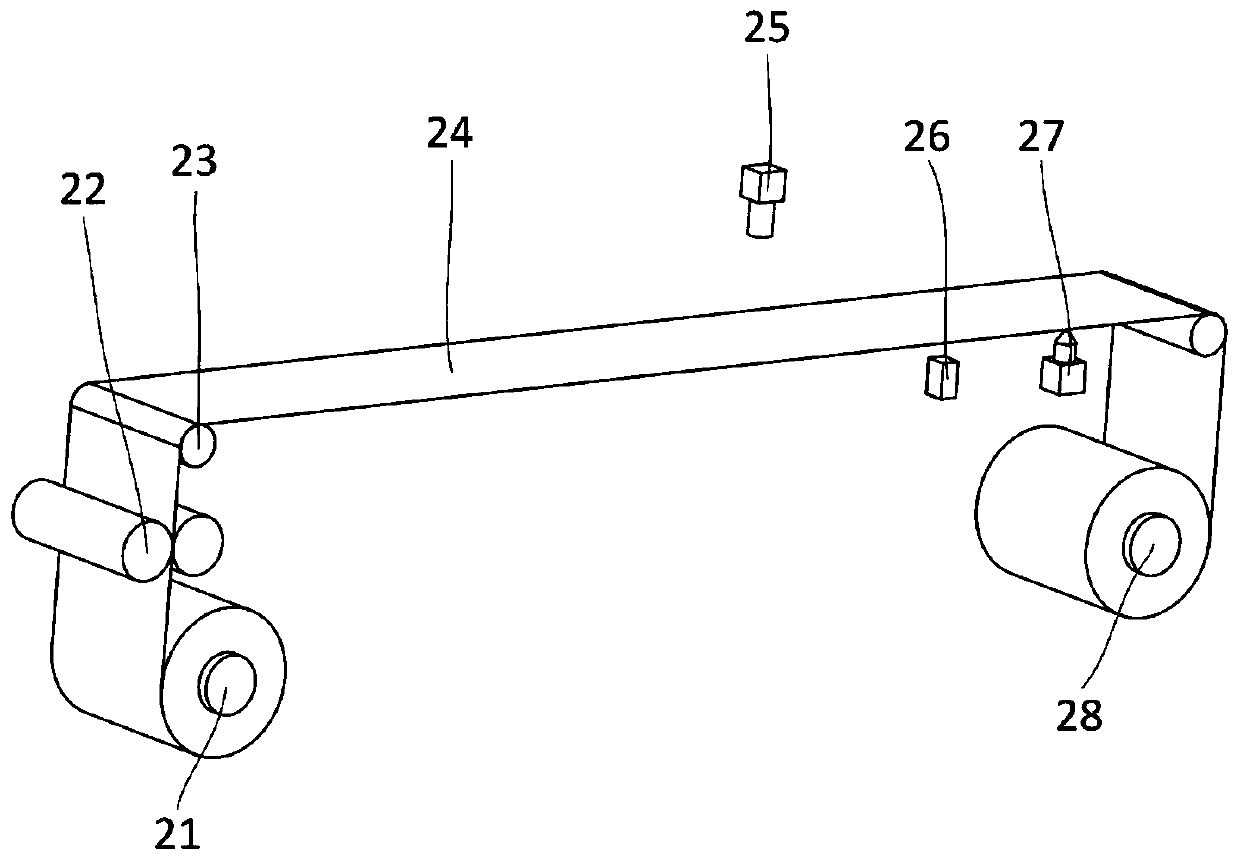

[0061] like figure 1 As shown, a micro-device laser lift-off mass transfer device based on a winding process provided by an embodiment of the present invention includes a micro-device lift-off transfer module 10, an auxiliary carrier tape module 20, a transition carrier tape module 30, a transfer carrier tape Module 40, substrate carrying module 50, micro-device filling module 60, curing module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com