Conductive ink, electronic label, its preparation method and radio frequency identification system

A conductive ink and electronic label technology, applied in the field of radio frequency identification, can solve the problem that rock corrosion cannot be monitored

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

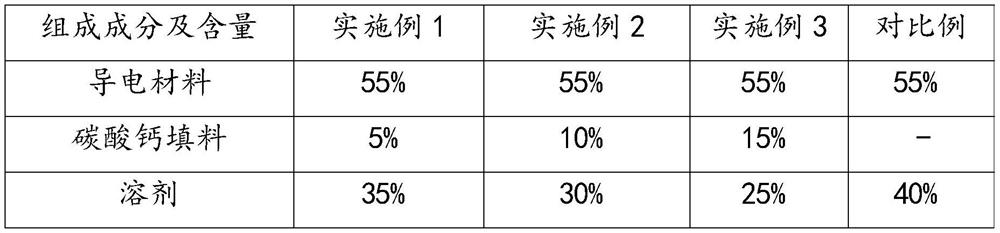

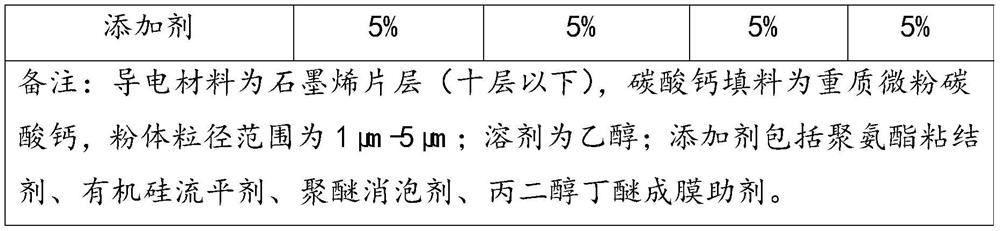

[0052] Conductive ink comprises conductive material, solvent, calcium carbonate filler and additive, and the content of each component of conductive ink is as table 1:

[0053] The content of each component of the conductive ink of table 1 (here all are mass percentages)

[0054]

[0055]

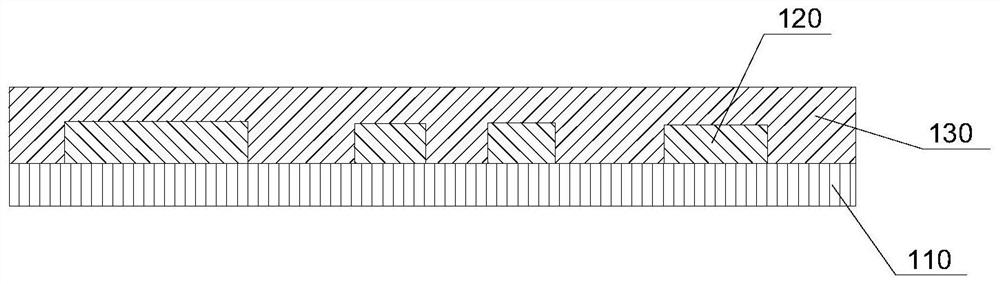

[0056] After the above-mentioned components are mixed according to the above-mentioned ratio, the conductive ink is uniformly dispersed to form a conductive ink, which is evenly coated on the top of the PET substrate by 100T screen printing method, and heated and cured at 120°C to obtain a conductive pattern with a thickness of 20 μm 120. Cover the surface of the conductive pattern 120 with a PE protective film 130, and heat emboss for 10s at a temperature of 45°C and a pressure of 0.5MPa to obtain figure 1 RFID tags shown.

[0057] The obtained RFID tags were subjected to environmental acidification and weathering simulation tests. The specific method was: the RFID tags prepared in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com