V belt wheel for skid resistance by centrifugal force

A technology of V-pulley and centrifugal force, which is applied to belts/chains/gears, components with teeth, portable lifting devices, etc., can solve problems such as slipping and friction reduction, reduce the probability of slipping, and improve Stability, friction-increasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

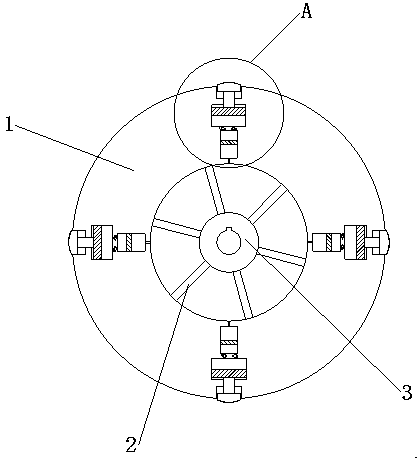

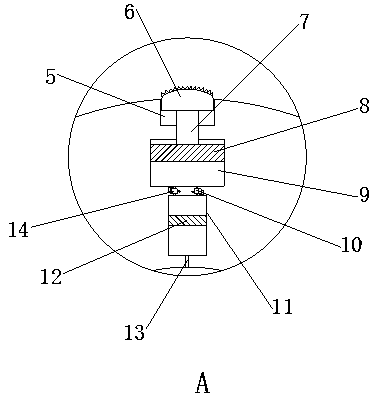

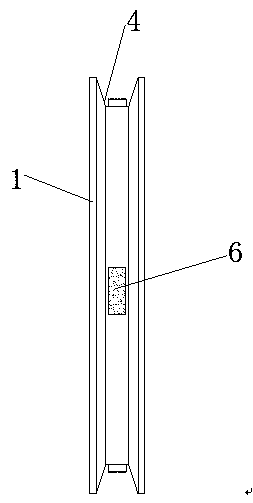

[0025] as attached figure 1 to attach Figure 4 Shown:

[0026] The present invention provides a V-belt pulley that utilizes centrifugal force to prevent slipping, including a rim 1, a spoke 2, a hub 3, a V-belt groove 4, an anti-slip chamber 5, an anti-slip block 6, a connecting rod 7, a connecting rod piston 8, and a movable chamber 9 , the first relief valve 10, the hydraulic cylinder 11, the hydraulic cylinder piston 12, the air hole 13, the second relief valve 14, the inner side of the wheel rim 1 is fixedly connected with the wheel spoke 2, and the other end of the wheel spoke 2 is fixedly connected with the wheel hub 3, the wheel The outer periphery of the rim 1 is provided with a V-belt groove 4, and the bottom of the V-belt groove 4 is provided with an anti-slip cavity 5, which is located inside the rim 1, and an anti-slip block 6 is arranged inside the anti-slip cavity 5, and the bottom of the anti-slip block 6 is fixed Connected with a connecting rod 7, the other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com