The invention relates to a transformer and a skeleton structure thereof, which can avoid virtual welding of the transformer

A transformer skeleton and transformer technology, applied in the field of transformers, can solve the problems of unstable electrical connection between the transformer and the PCB board, inability to paste the solder to melt, uneven heating of the welding feet, etc., so as to improve the stability of the electrical connection and avoid the The effect of virtual welding and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

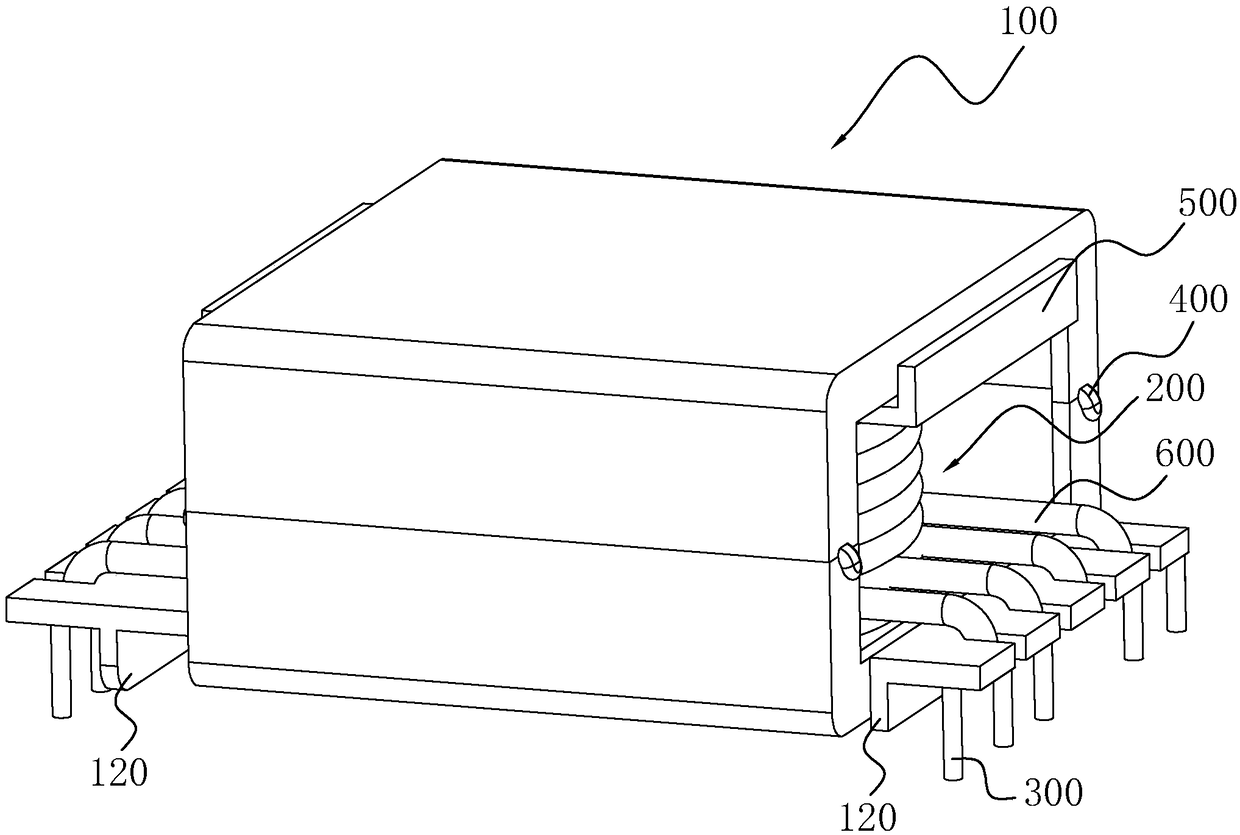

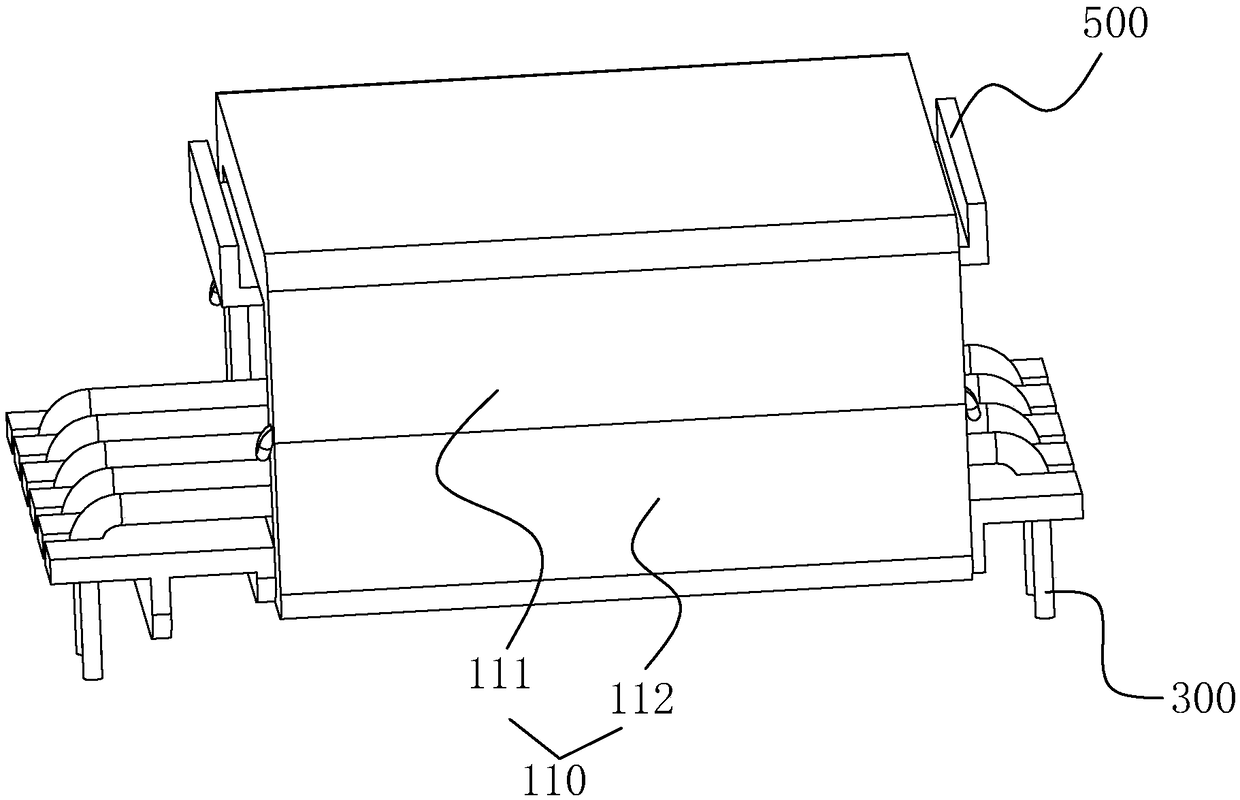

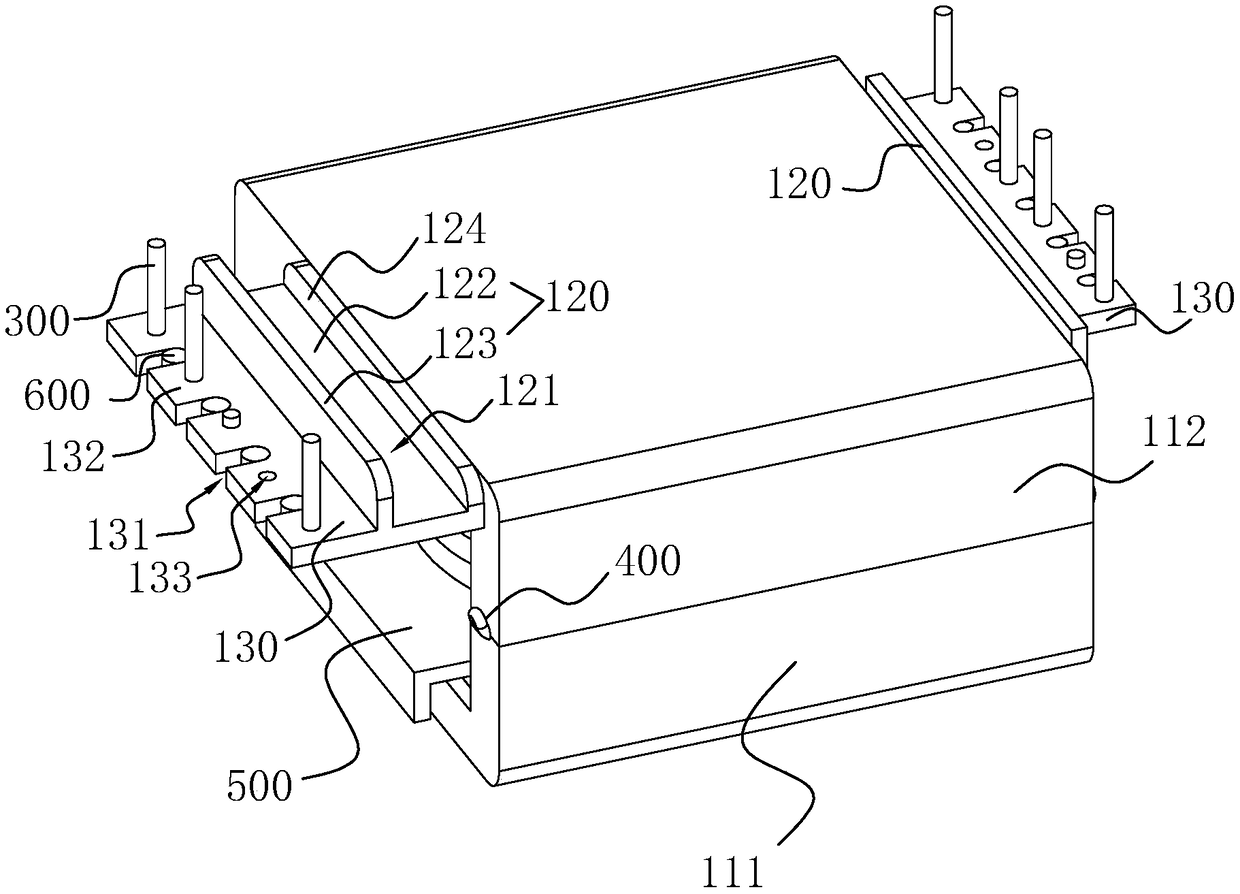

[0040] A kind of transformer that avoids the virtual welding of transformer, refer to figure 1 , including a skeleton structure 100 , a coil 200 disposed on the skeleton structure 100 , and a welding foot 300 connected to the coil 200 . In this example, combined with figure 1 with figure 2 , the skeleton structure 100 includes a casing 110 and support feet 120 disposed on both sides of the casing 110 . The housing 110 includes an upper housing 111 and a lower housing 112. The upper housing 111 and the lower housing 112 are combined to form a cavity for installing the coil 200. After the coil 200 is installed, the upper housing 111 and the lower housing 112 The connection is fixed by dispensing 400. In this embodiment, the dispensing glue 400 is located on both sides of the supporting legs 120, which can maintain the smoothness of the other two si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com