Battery pack equalization pressurization equipment, battery pack preparation method and battery module

A technology for pressurized equipment and battery packs, applied in battery pack components, secondary battery manufacturing, secondary batteries, etc., can solve problems such as low production efficiency, cumbersome steps, and differences in contact resistance, so as to improve production efficiency and improve production efficiency. Consistency of contact resistance, effects of high electrical connection stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

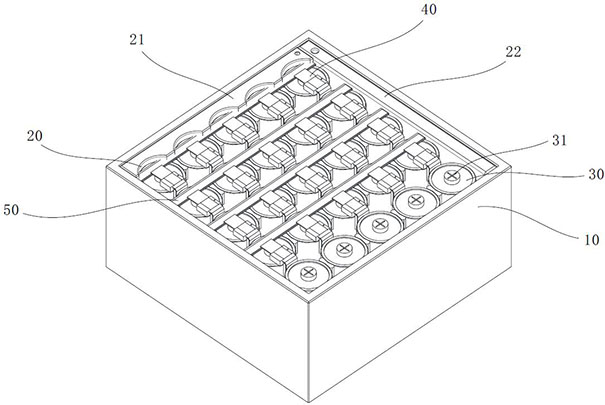

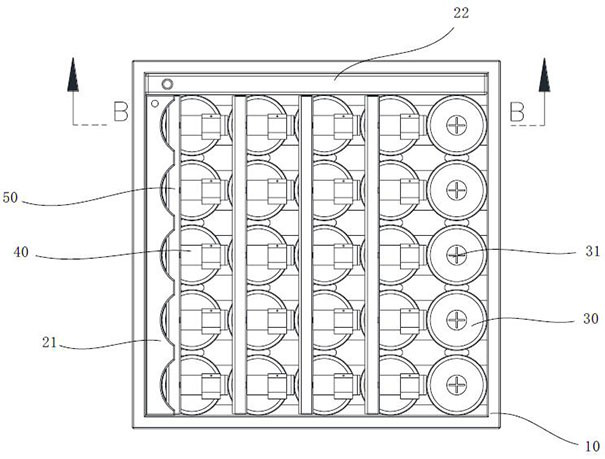

[0053] This example 1 provides a battery pack equalizing pressurization equipment, which is used to prepare the single cylindrical battery 30 into a CTP module that is connected in series within the row and connected in parallel between the rows, and is especially suitable for the preparation process of the power battery unit of a new energy vehicle. And it is also applicable to low-speed electric vehicles, electric bicycles and other energy storage products.

[0054] In this embodiment, the single cylindrical battery 30 is a power battery with high energy density, which can be selected from 18650 batteries, 21700 batteries, 46800 batteries, etc., but is not limited thereto.

[0055] like Figure 1-Figure 4 As shown, the battery pack equalizing pressurization device in this embodiment does not include the single cylindrical batteries 30 shown in the figure, but is provided solely as a structure for grouping the single cylindrical batteries 30 .

[0056] This embodiment provid...

Embodiment 2

[0069] refer to Figure 1-Figure 4 , this embodiment provides a method for manufacturing a battery pack using the battery pack equalization pressurization device described in Embodiment 1, including:

[0070] 1. Put a number of single cylindrical batteries 30 into the frame part 10 of the pressurizing device in sequence to form a rectangular battery array;

[0071] Provide several upright single cylindrical batteries 30, set structural glue 60 on the bottom plate of the frame part 10, start from a corner of the frame part 10, put the single cylindrical batteries 30 in sequence next to the baffle, and arrange them as batteries array;

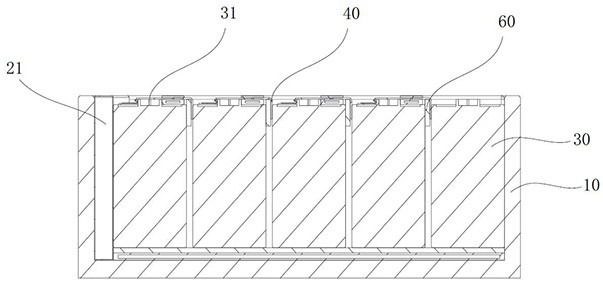

[0072] 2. Structural glue 60, and / or connecting bridge 40, and / or cold welding glue, and / or insulating connectors are arranged between the side shell poles of adjacent single cylindrical batteries in the battery array;

[0073] The series connection between the top pole 31 of the adjacent single cylindrical battery 30 and the shell pole is real...

Embodiment 3

[0092] This embodiment provides a battery pack manufactured by using the equipment described in Embodiment 1 or a battery module manufactured by using the method described in Embodiment 2.

[0093] As described in Embodiment 2 above, the battery module includes a combination of a frame part 10 and a battery array (and its internal electrical connectors and insulators); preferably, the battery module includes a combination of several frame parts 10 and a battery array .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com