Miniature workpiece sorting equipment

A workpiece and sorting technology, applied in sorting and other directions, can solve problems such as difficult to eliminate, fall off, time-consuming and laborious, etc., and achieve the effects of convenient and fast monitoring, standard drawing strength, and convenient sorting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

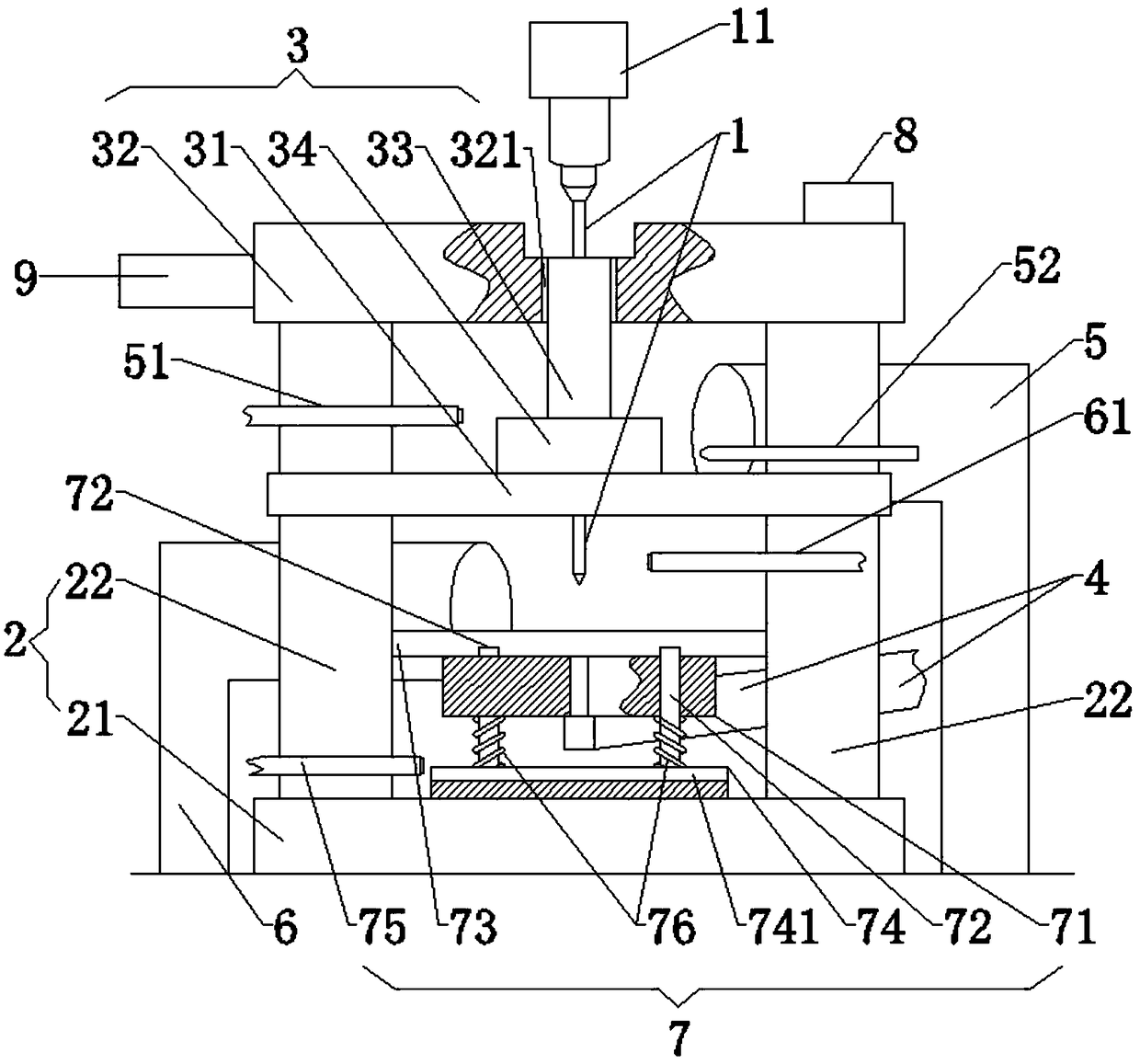

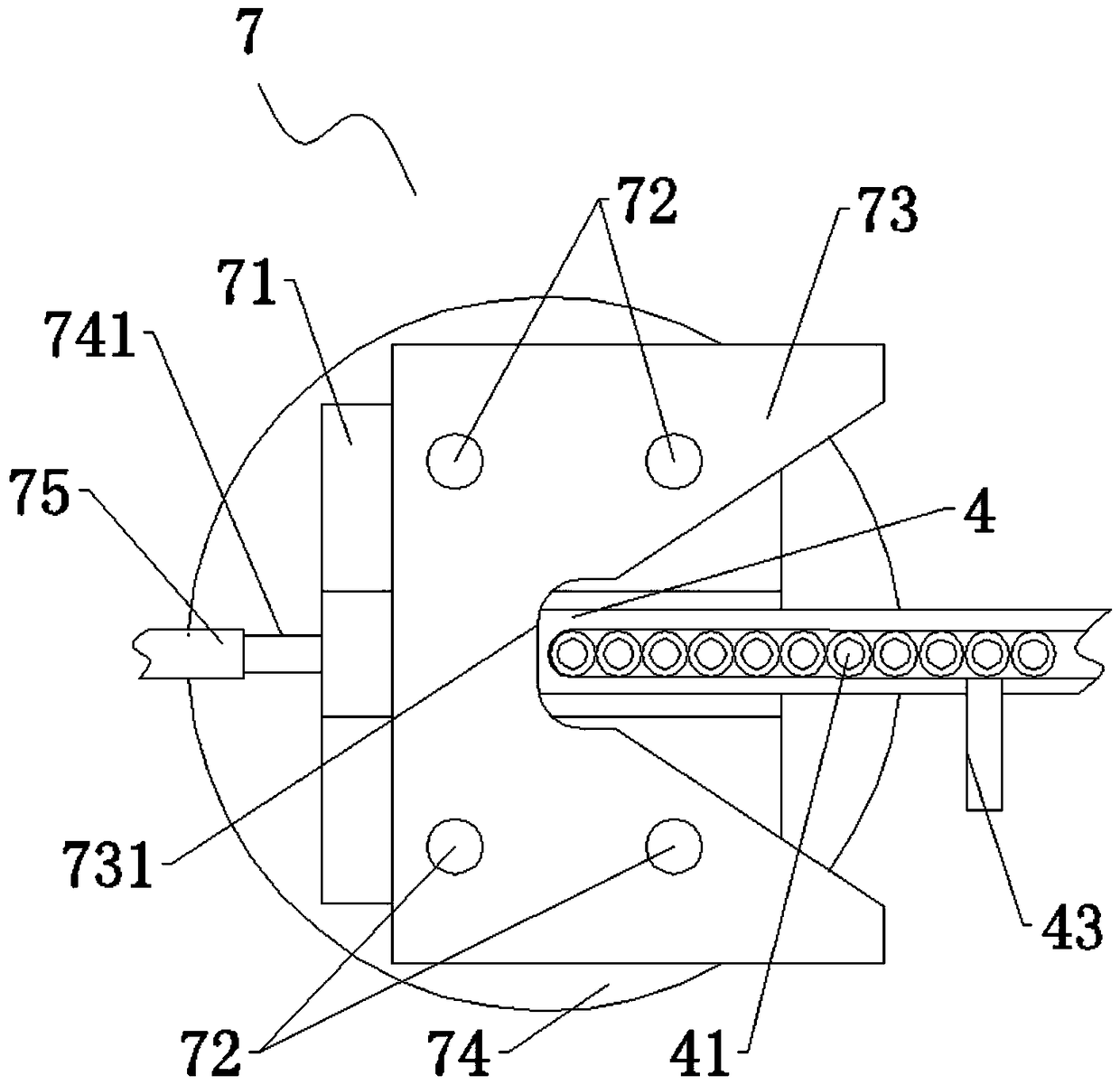

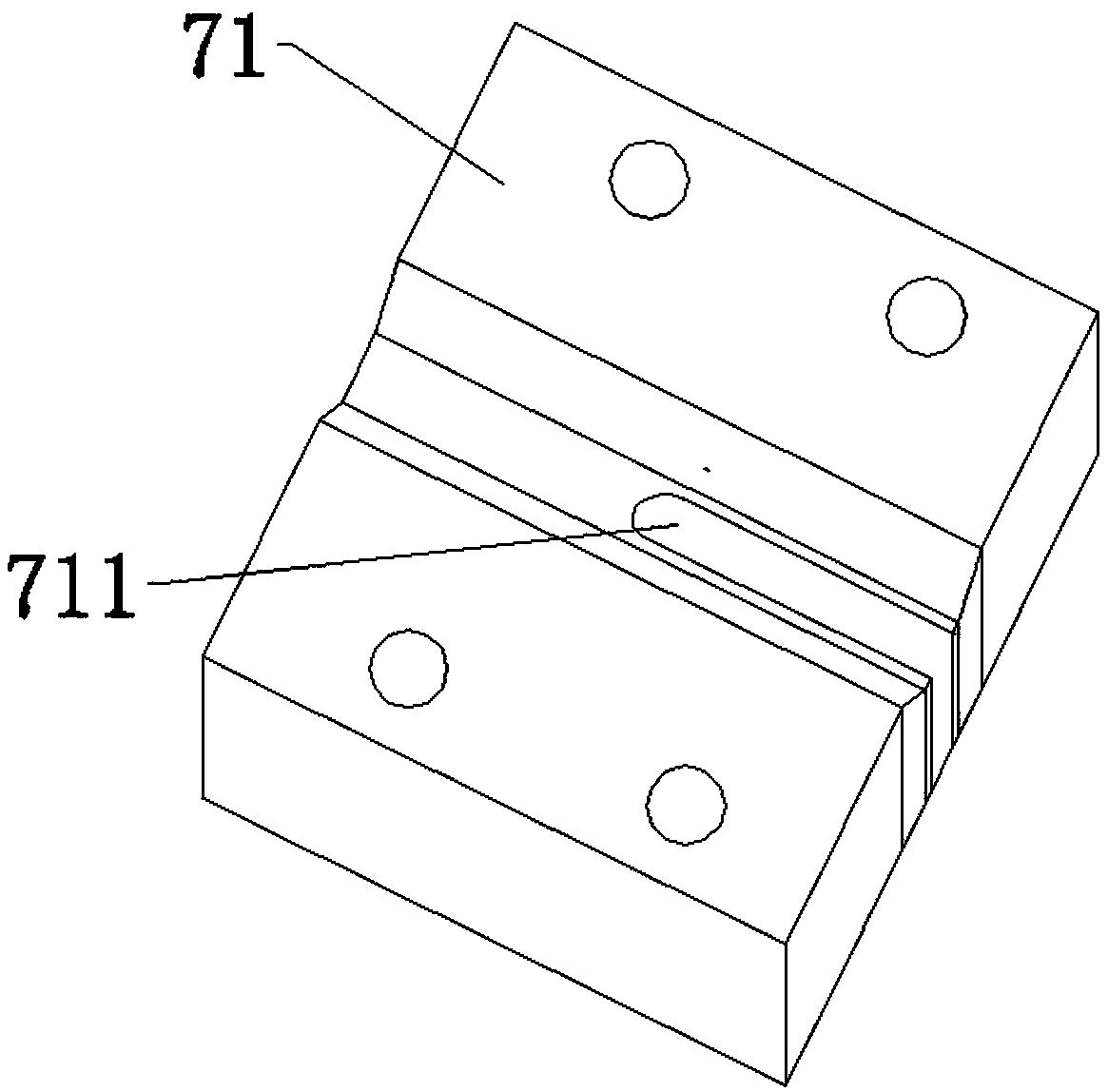

[0025] see Figures 1 to 6 As shown, the present invention provides a technical solution: a sorting device for micro workpieces, including a reclaiming rod 1 that can reciprocate up and down, and a gravity sorting device 3 that can pull the workpiece 41 to be tested. 1. Pass through the gravity sorting device 3. One side of the gravity sorting device 3 is also provided with an upper air selection pipe 51 that can blow away the workpiece 41 to be tested. The downwind selection tube 61 of the workpiece 41 is set by the gravity sorting device 3 with the standard pulling force. Because the gravity is constant, as long as the weight of the gravity standard block 34 is determined, the gravity sorting device 3 can pull the workpiece 41 to be tested. The force is constant, which avoids the inaccuracy of pulling force with human hands and measuring tools each time. Through the standard pulling force, the equipment can perform standardized testing, which is more convenient and accurate....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com