Fixture tightness adjusting device for bench worker

A technology of adjusting device and tightness, applied in the direction of manufacturing tools, clamps, etc., can solve the problems of unstable clamping, inability to lubricate the interior of the clamp, too loose clamping of the clamp, etc., to increase convenience and diversify clamping methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

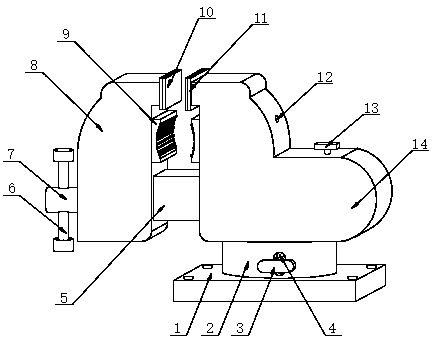

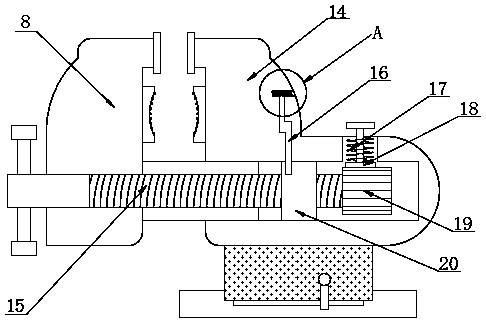

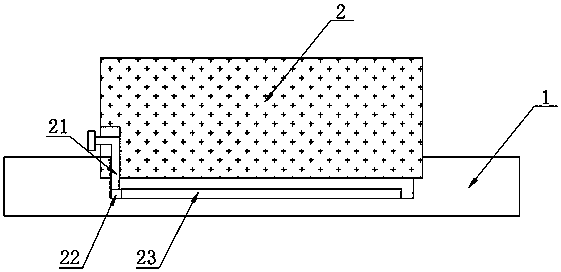

[0021] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0022] Example: such as Figure 1-4 As shown, the present invention provides a technical solution, a clamp tightness adjustment device for a fitter, including a base 1, a rotating seat 2, an adjustment handle 3, a chute 4, a connecting column 5, an adjustment crank 6, an adjustment rod 7, a front Clamp seat 8, first clamp 9, anti-skid pad 10, second clamp 11, fuel filler 12, adjustment handle 13, rear clamp seat 14, transmission thread 15, oil delivery pipe 16, fixed spring 17, first block 18, second A fixed latch 19, a fixed seat 20, a transmission rod 21, a second block 22, a second fixed latch 23, a return spring 24 and a plug 25, the top of the base 1 is rotatab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com