Polyurethane foaming machine

A technology of polyurethane and foaming machine, applied in the field of polyurethane foaming machine, can solve the problems of unstable polyurethane foaming process, poor molding precision of polyurethane foaming material, difficulty in producing high-quality finished products, etc., so as to improve the stirring effect and improve the Mixing effects, effects that improve usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

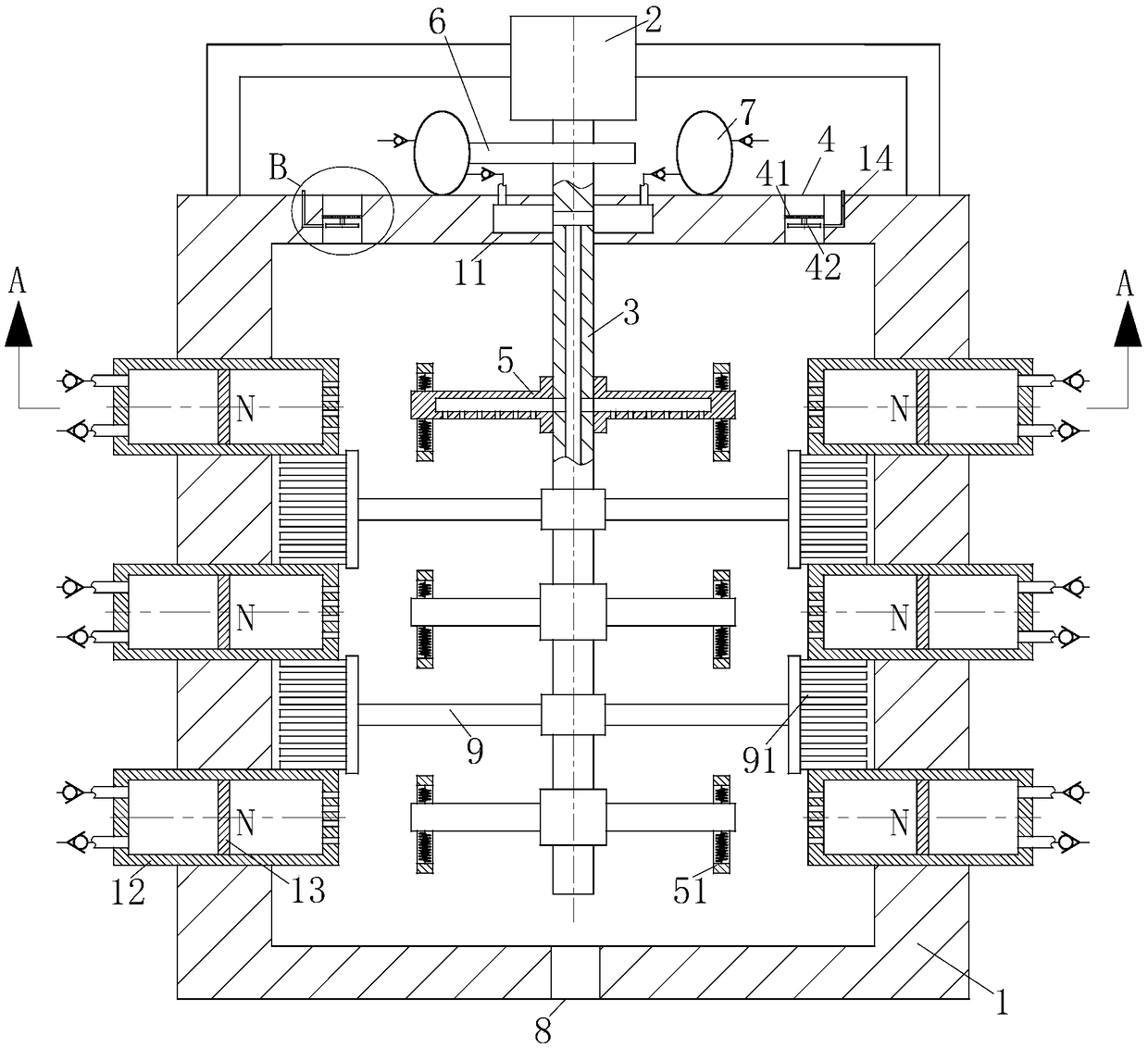

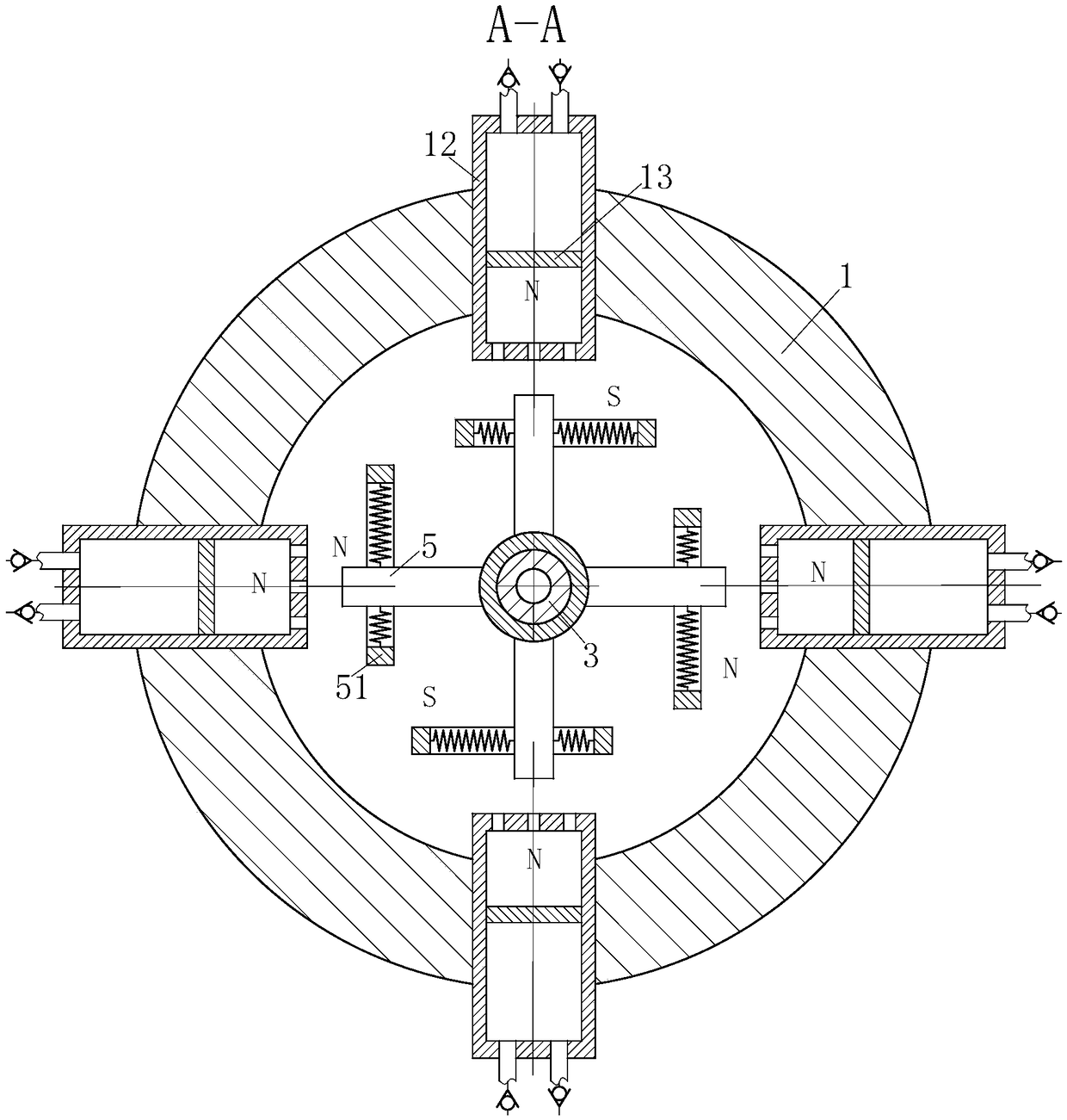

[0018] use Figure 1-Figure 3 The structure of the polyurethane foam machine which concerns on one Embodiment of this invention is demonstrated below.

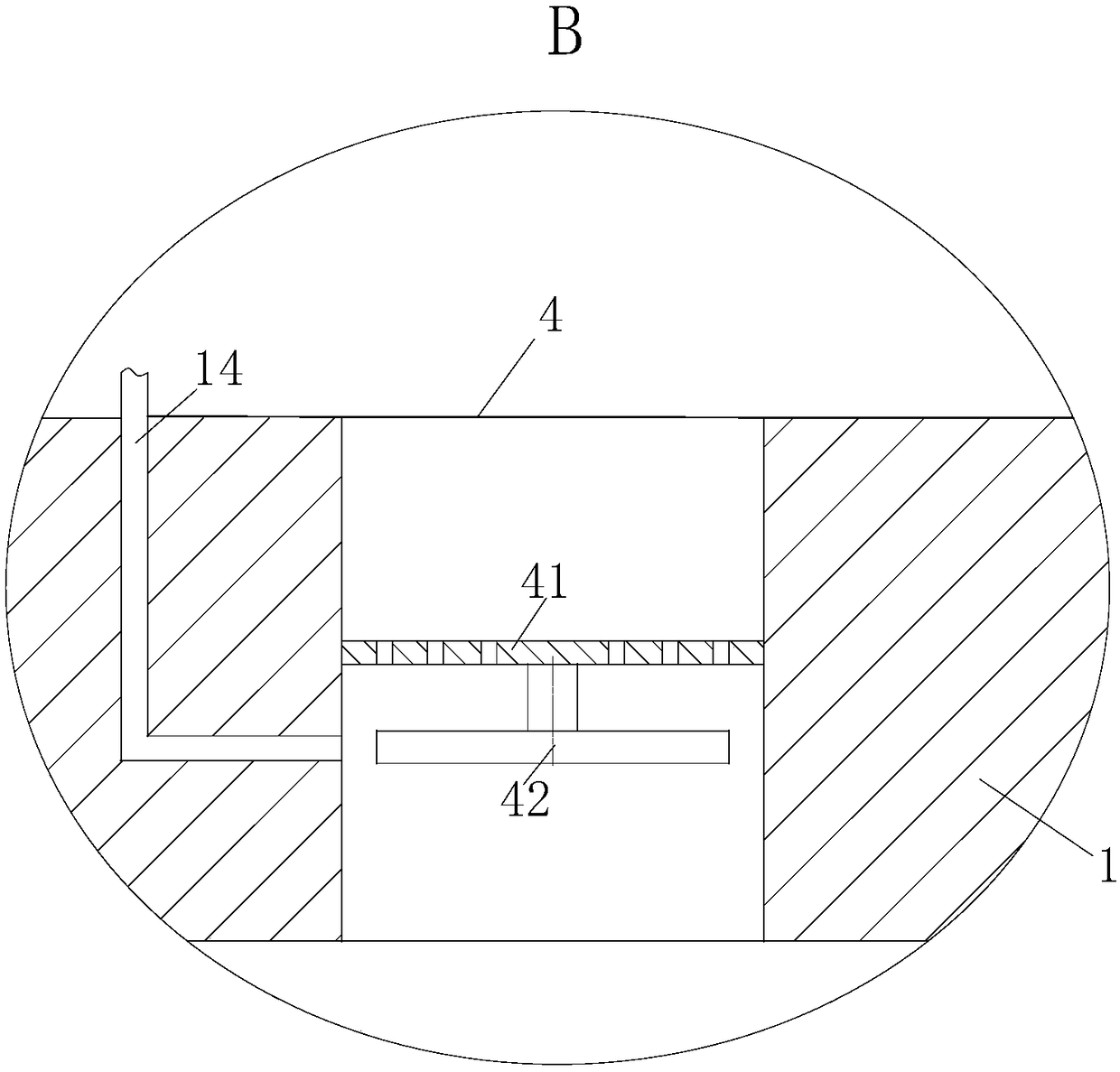

[0019] Such as figure 1As shown, a polyurethane foaming machine according to the present invention includes a housing 1, a motor 2, a connecting shaft 3, a feed inlet 4, a No. 1 stirring rod 5, a cam 6, an air bag 7 and a discharge outlet 8; The motor 2 is installed on the top of the housing 1; the connecting shaft 3 is installed inside the housing 1 through the output shaft of the motor 2, and a channel is provided inside the connecting shaft 3; the number of the feeding ports 4 is two, and the feeding ports 4 are about It is symmetrically arranged on the top of the housing 1, and the feeding port 4 is used to inject polyurethane A material and B material into the housing 1 respectively; multiple groups of No. 1 stirring rods 5 are fixedly installed on the connecting shaft 3, and each group of The number of No. 1 stirring r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com