Printing paper discharge device

A discharge device and paper technology, applied in the direction of paper product packaging, packaging, transportation and packaging, etc., can solve the problems of damaged outer packaging and insufficient aesthetics, and achieve the effect of convenience, simple structure and easy use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

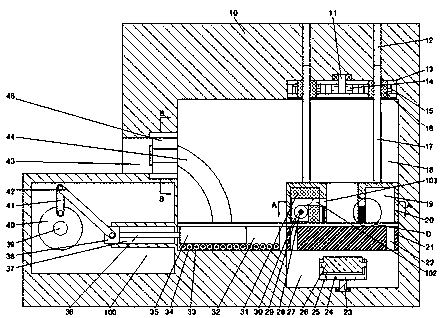

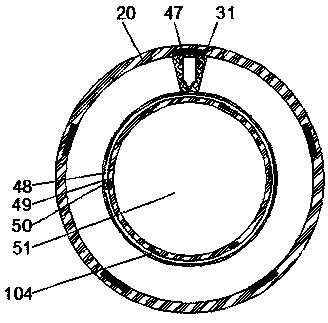

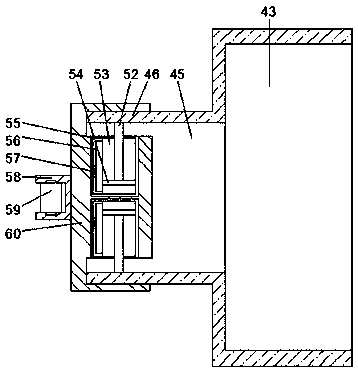

[0020] Such as Figure 1-6As shown, a printing paper discharge device of the present invention includes a frame 10 located at the frame 10, the frame 10 is provided with a feed chamber 43 opening to the left, and the frame 10 is provided with a The processing chamber 18 connected to the right side of the feed chamber 43, the feed chamber 43 and the rear end wall of the processing chamber 18 are provided with a clamp sliding chamber 44, and the frame 10 is provided with a The translation chamber 100 of the lower end wall of the material chamber 43, the lower end wall of the processing chamber 18 is provided with a connected push plate chamber 32, and the frame 10 is provided with a material storage chamber 27 positioned at the lower end wall of the processing chamber 18, so The rear end wall of the translation chamber 100 is provided with a transmission chamber 86, the frame 10 is provided with a gear chamber 65 located at the rear end wall of the feed chamber 43, and the frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com