Speed regulation control system, aerial work platform and speed regulation method

A high-altitude work platform and control system technology, which is applied in the direction of lifting devices, can solve the problems of high-altitude work platform safety and hidden dangers, and achieve the effect of reducing safety hazards and improving safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

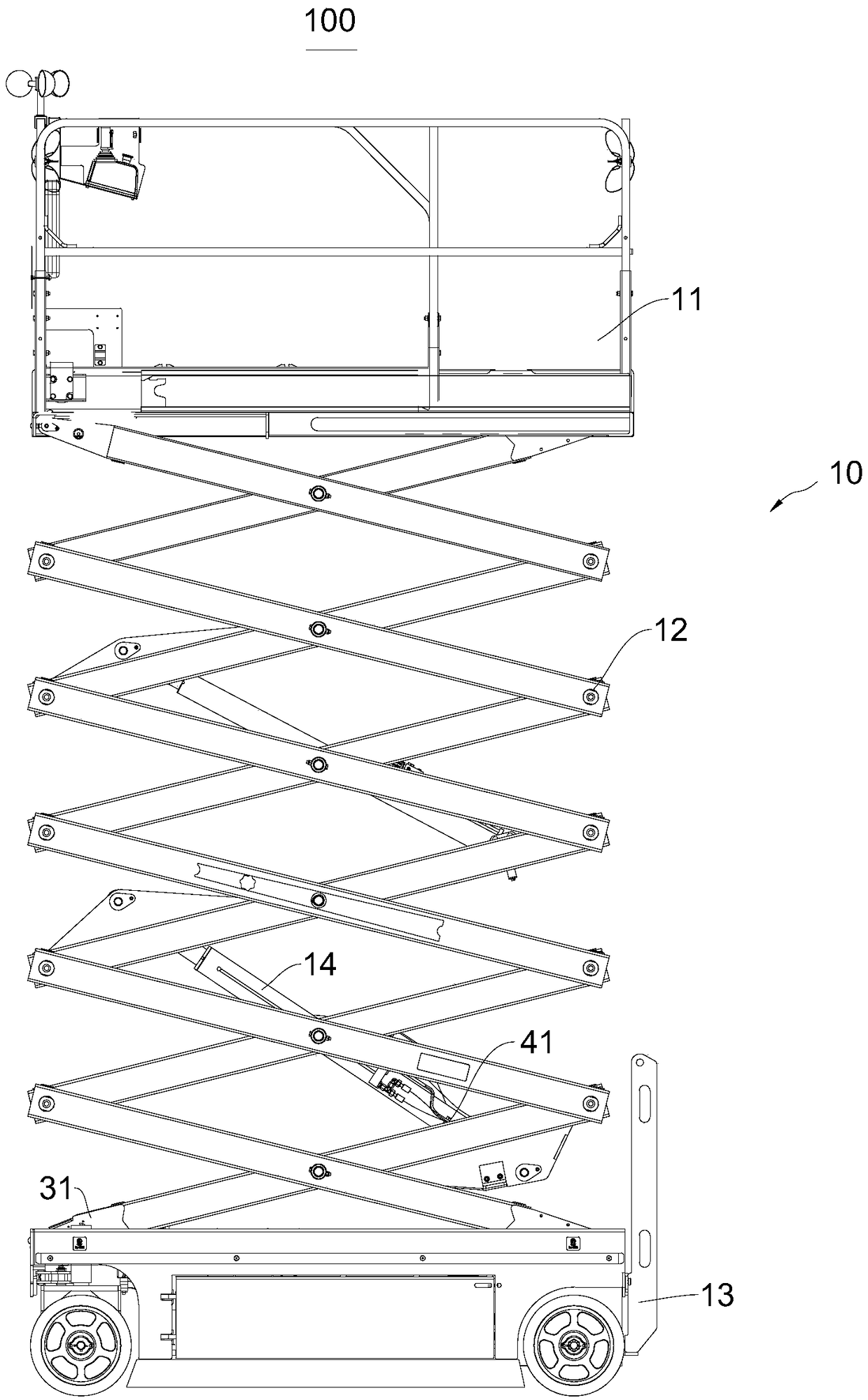

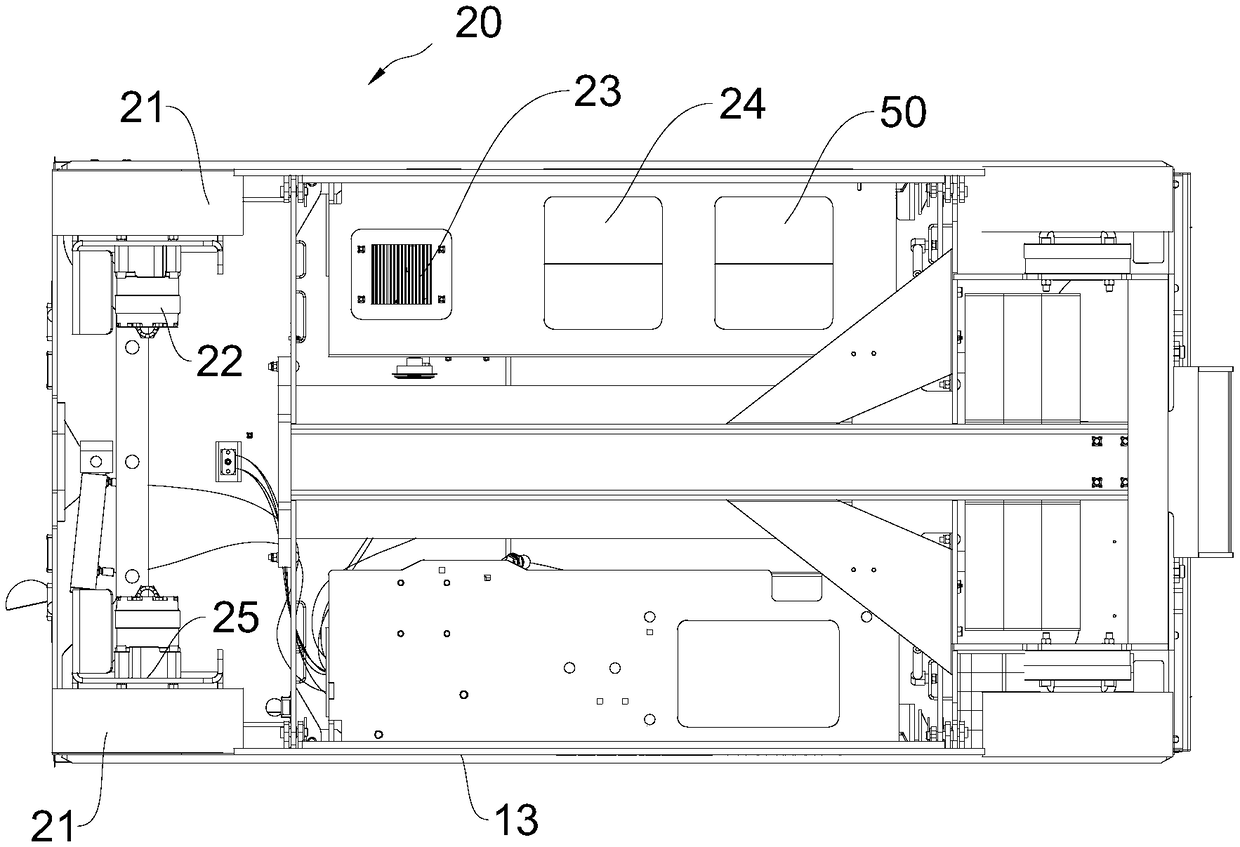

[0045] Please refer to Figure 1-Figure 6 , this embodiment provides an aerial work platform 100, and correspondingly, a speed regulation control system is provided.

[0046] The aerial work platform 100 includes the speed control system, which has all the functions of the speed control system.

[0047] Specifically, combine figure 1 and figure 2, the aerial work platform 100 includes a body 10 and a driving device 20, the driving device 20 is used to drive the body 10 to move, more specifically, the body 10 is a scissor type aerial work platform, which includes a working part 11, a driving cylinder 14, a folding frame 12 and the chassis 13, the working part 11, the folding frame 12 and the chassis 13 are connected in sequence, and the drive cylinder 14 is used to drive the folding frame 12. During work, the chassis 13 is placed on the ground, and the driving device 20 is connected to the chassis 13 for driving the chassis 13 to move. The driving cylinder 14 drives the fol...

Embodiment 2

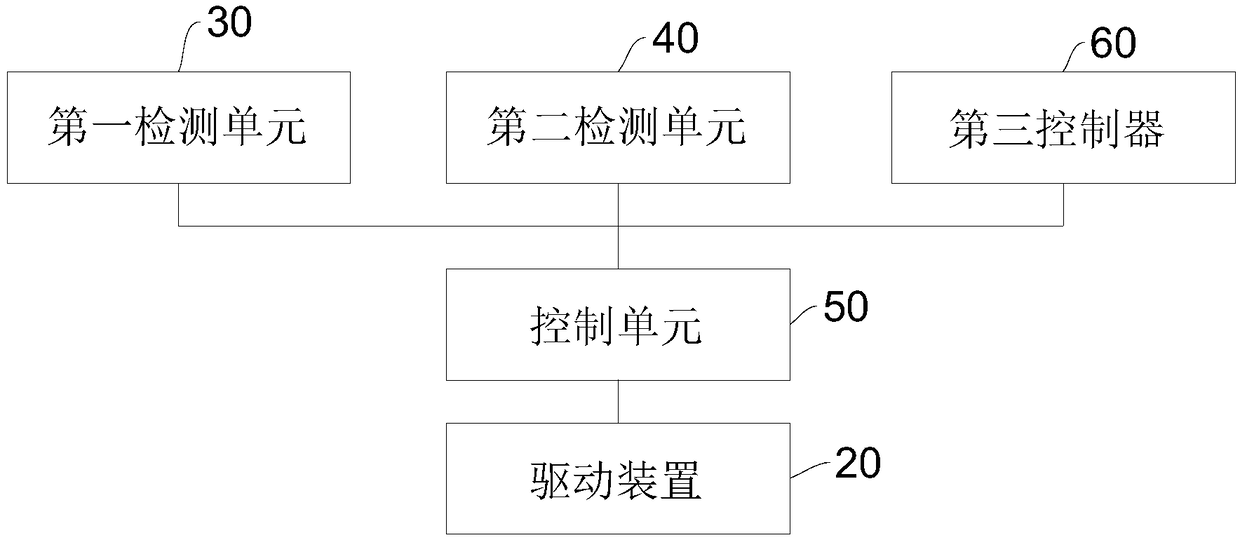

[0081] This embodiment provides a speed regulation method, which is realized by using the above-mentioned speed regulation control system or the above-mentioned aerial work platform 100. The speed regulation method includes:

[0082] Outputting a first signal representing the height of the working part 11;

[0083] Outputting a second signal representing the load of the working part 11;

[0084] Receive the first signal and the second signal and perform arithmetic processing, and control the driving device 20 .

[0085] In summary, the present invention provides a speed regulation control system, through the first signal detected by the first detection unit 30 and the second signal detected by the second detection unit 40, the control unit 50 can Calculate and process with the second signal to obtain the maximum traveling speed of the aerial work platform 100, and control the driving device 20 to realize the control of the traveling speed of the aerial work platform 100, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com