600MPa-grade thin hot-rolled automobile structural steel produced by short process, and method

A short-process technology for automotive structural steel, applied in the field of 600MPa-level thin-gauge hot-rolled automotive structural steel, can solve the problems of unstable rolling process, poor plate shape, coil shape, and no more than 85%, achieving plate shape and Excellent roll shape, satisfying the effect of greening and improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below:

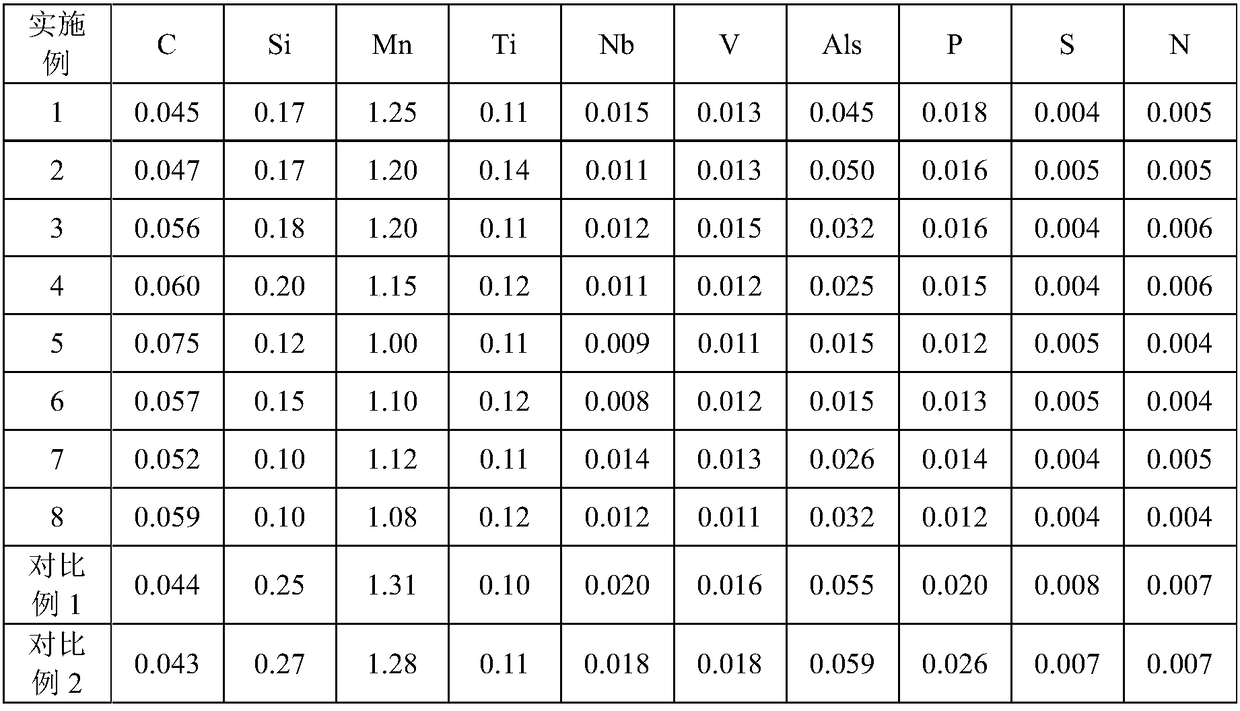

[0042] Table 1 is a list of chemical components of each embodiment and comparative example of the present invention;

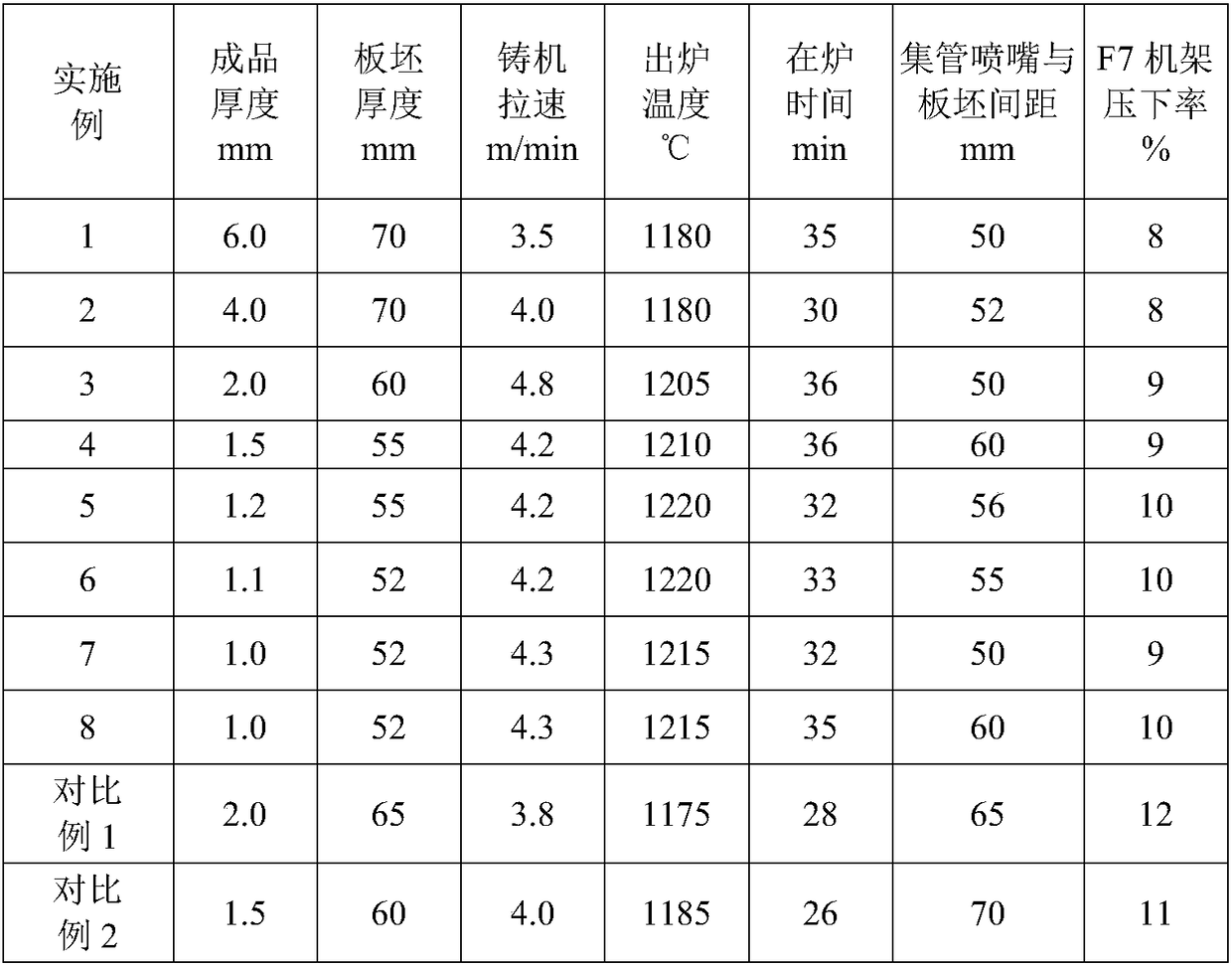

[0043] Table 2 is a list of main process parameters of each embodiment and comparative example of the present invention;

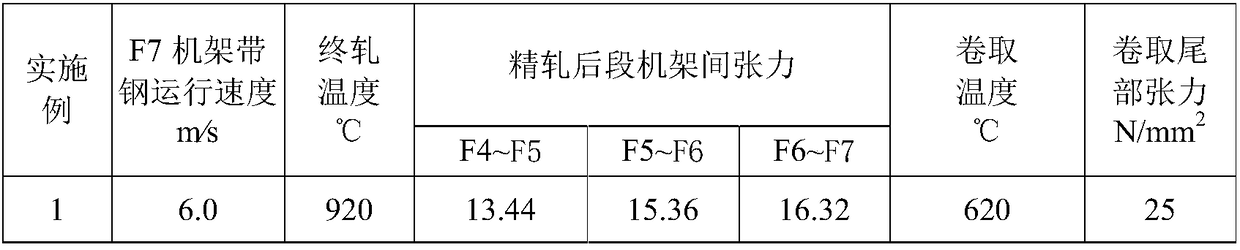

[0044] Table 3 is a list of the mechanical performance detection and quality conditions of each embodiment and comparative example of the present invention.

[0045] Each embodiment of the present invention is produced according to the following steps:

[0046] 1) After conventional smelting, the thickness of the cast slab is controlled to 52~70mm; and the drawing speed is controlled at 3.5-4.8m / min; during the casting process: the lower drawing speed is 0.4m / min, the rising drawing speed is 0.1m / min for control;

[0047] 2) Perform soaking of thin slabs, control the furnace temperature at 1180~1220℃, and the furnace time not less than 30min;

[0048] 3) Two consecutive descaling: the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com