Selective electroplating anode water gallery device

A technology of partial electroplating and anode water, applied in electrodes and other directions, can solve the problems of waste of raw materials and low efficiency, and achieve the effect of avoiding waste of raw materials and convenient disassembly, cleaning and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

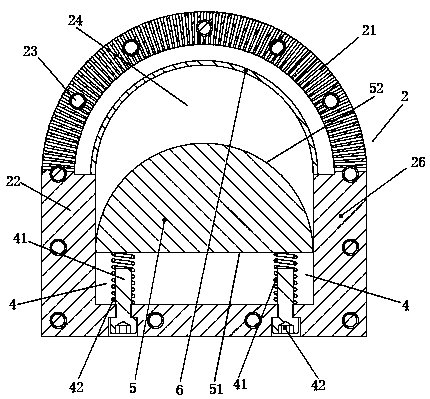

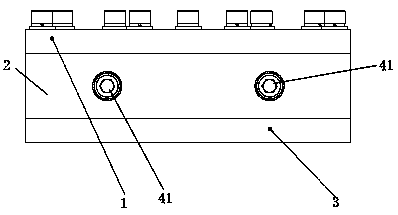

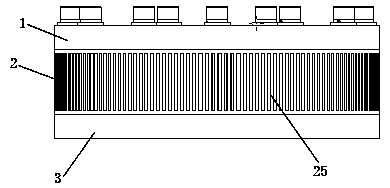

[0019] Such as Figures 1 to 4 As shown, a partial electroplating anode water corridor device includes an upper clamping plate 1 , a middle frame body 2 , a lower clamping plate 3 , an abutment block 5 , a telescopic component 4 , and a limiting mesh plate 6 . The middle frame 2 is clamped and installed between the upper clamping plate 1 and the lower clamping plate 2; the telescopic assembly 4 and the abutment block 5 are installed inside the middle frame 2; the middle Two telescopic assemblies 4 are respectively installed inside one side of the frame body 2; a limit screen 6 is installed inside the other side of the middle frame body 2; the telescopic assembly 4 includes a sleeve screw 41 and a drive The elastic body 42; the socket screw 41 is fixedly installed inside one side of the middle frame body 2; a driving elastic body 42 is sleeved ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com