Overflow system

An overflow and overflow groove technology, used in safety valves, engine components, balance valves, etc., can solve the problems of left and right swaying of the valve core, low valve core service life, excessive deformation of the sealing ring, etc., and achieve convenient overflow function. , long service life, uniform force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

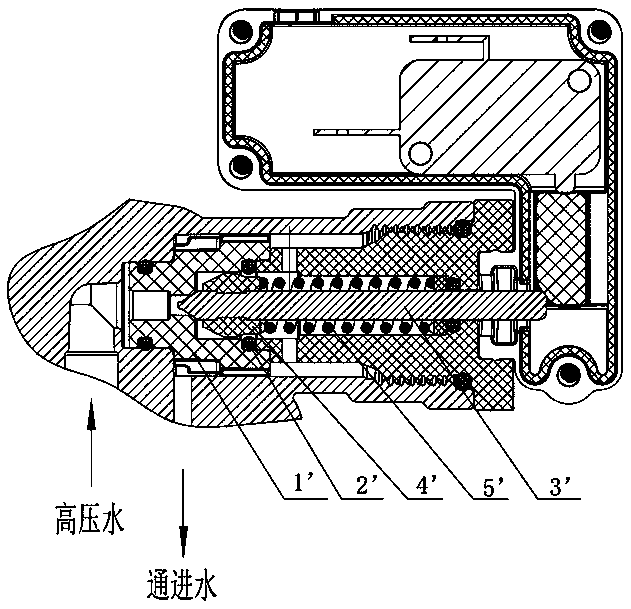

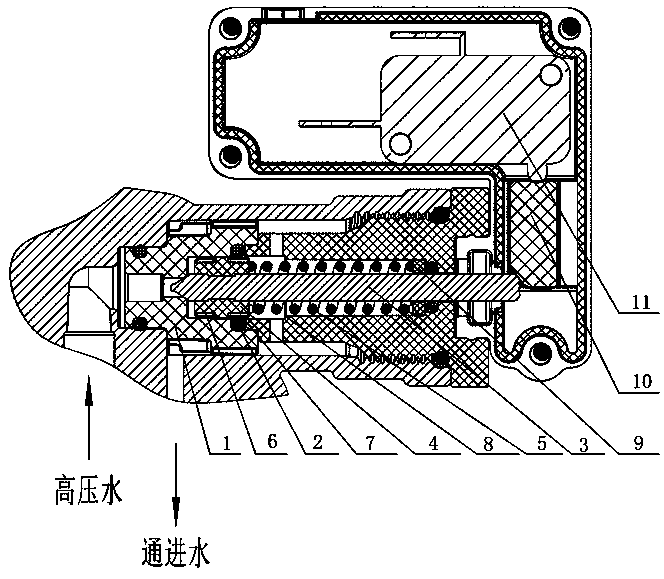

[0018] Specific embodiment one, an overflow system, including a valve seat 1, a sealing ring 2 embedded in the valve seat 1, a valve stem 3 arranged in the valve seat 1, a valve core 4 sleeved on the valve stem 3 and Spring 5 for resisting spool 4, wherein:

[0019] The spool 4 is cylindrical, and the outer circumference of the spool 4 is in interference fit with the sealing ring, and in the process of the spool 4 moving back and forth in the valve seat 1, the spool 4 is always matched with the sealing ring 2; and the valve The core 4 is divided into three parts along the direction of the valve stem, from top to bottom are the first part, the second part and the third part, and the outer circumference of the first part is provided with an upper overflow groove 6, and the outer circumference of the third part is provided with The specific thicknesses of the three parts of the lower overflow tank 7 are determined according to the actual situation, but in this specific embodiment...

specific Embodiment 2

[0023] The second embodiment differs from the first embodiment in that the valve core 4 in the second embodiment is cylindrical.

specific Embodiment 3

[0024] The difference between the third embodiment and the first embodiment is that in the third embodiment, a limit step 8 is provided in the valve seat, so that when the valve core 4 moves, it will be blocked by the limit step 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com