Array substrate and display device

A technology for array substrates and display areas, applied in identification devices, static indicators, instruments, etc., can solve problems affecting signal transmission, electrostatic breakdown, and signal line 11 and 12 disconnection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

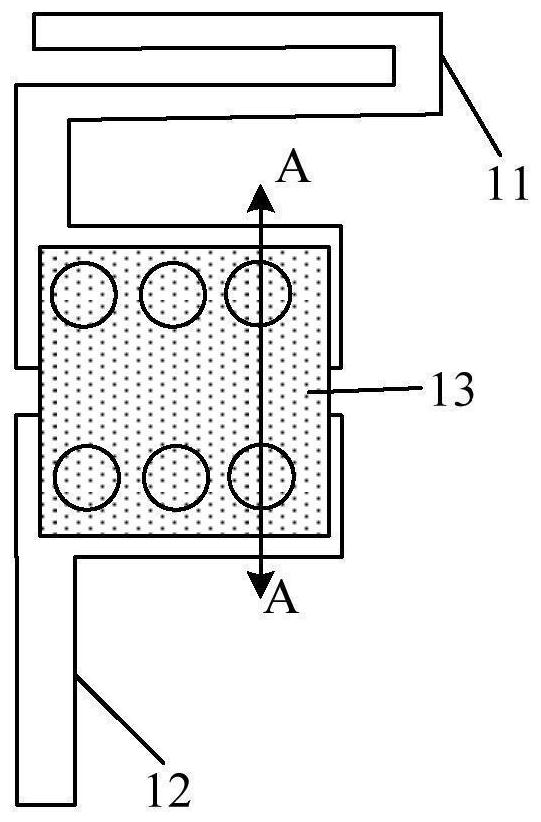

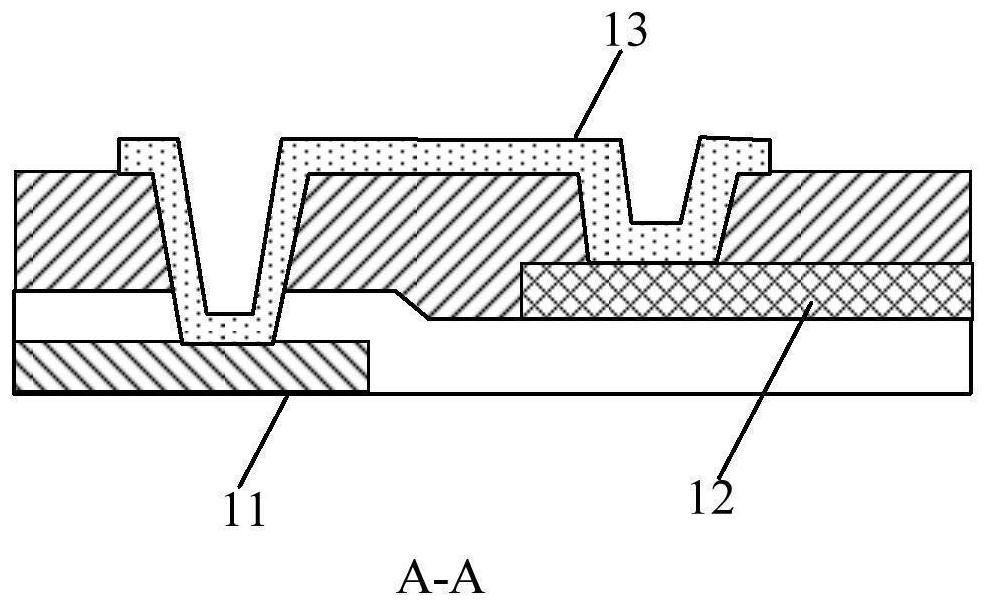

Embodiment 1

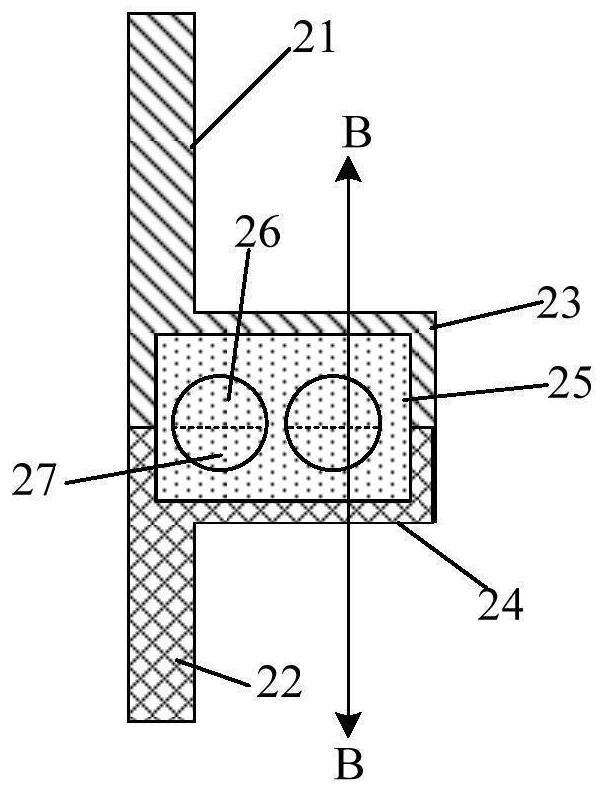

[0043] Specifically, the first connection mode of the first conductive part 23 and the second conductive part 24 is as follows: image 3 and Figure 4 As shown, wherein, a part (about half) of the orthographic projection of the first conductive portion 23 on the substrate 20 is located within the range of the orthographic projection of the second conductive portion 24 on the substrate 20, and the other part is located within the range of the orthographic projection of the second conductive portion 24 on the substrate 20. Outside the orthographic projection on the substrate 20. The orthographic projection of the second via hole 27 on the substrate 20 is located within the range of the orthographic projection of the second conductive portion 24 on the substrate 20, and the orthographic projection of the first via hole 26 on the substrate 20 is located within the range of the second conductive portion 24 on the substrate 20. The orthographic projection on the substrate 20 is out...

Embodiment 2

[0045] The second connection method of the first conductive part 23 and the second conductive part 24 is as follows: Figure 5 and Figure 6 As shown, most or all of the orthographic projection of the first conductive portion 23 on the substrate 20 is within the range of the orthographic projection of the second conductive portion 24 on the substrate 20 . The second conductive portion 24 includes at least one slit 241 penetrating through the second conductive portion 24, the orthographic projection of the first via hole 26 on the substrate 20 is within the range of the orthographic projection of the slit 241 on the substrate 20, and the second The projection of the via hole 27 on the substrate is located outside the range of the orthographic projection of the slit 241 on the substrate 20, and the orthographic projection of each first via hole 26 does not overlap with the orthographic projection of the corresponding second via hole 27 and mutually adjacent. and Figure 4 In ...

Embodiment 3

[0049] The third connection method of the first conductive part 23 and the second conductive part 24 is as follows: Figure 7 and Figure 8 As shown, in order to clearly see the structure of the first conductive part 23 and the second conductive part 24 and the connection relationship between the two, in Figure 7 In the figure, the connection structure 25 is represented by a transparent film layer without pattern filling. The first conductive part 23 includes a first comb handle part 23a and a plurality of first comb tooth parts 23b arranged at intervals connected to the first comb handle part 23a, and the area where the first conductive part 23 is located is the first comb handle part 23a, The sum of the areas where the plurality of first comb-tooth portions 23b and the intervals between the first comb-tooth portions 23b are located. The second conductive part 24 includes a second comb handle part 24a and a plurality of second comb tooth parts 24b connected at intervals co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com