Stator winding structure of an axial flux motor,

A stator winding and axial flux technology, applied in the direction of the shape/style/structure of the winding conductor, can solve the problems of mutual interference of the stator coils and affect the installation of the motor shaft, and achieve reasonable coil arrangement, easy to realize folding and shaping , The effect of reducing the extension length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

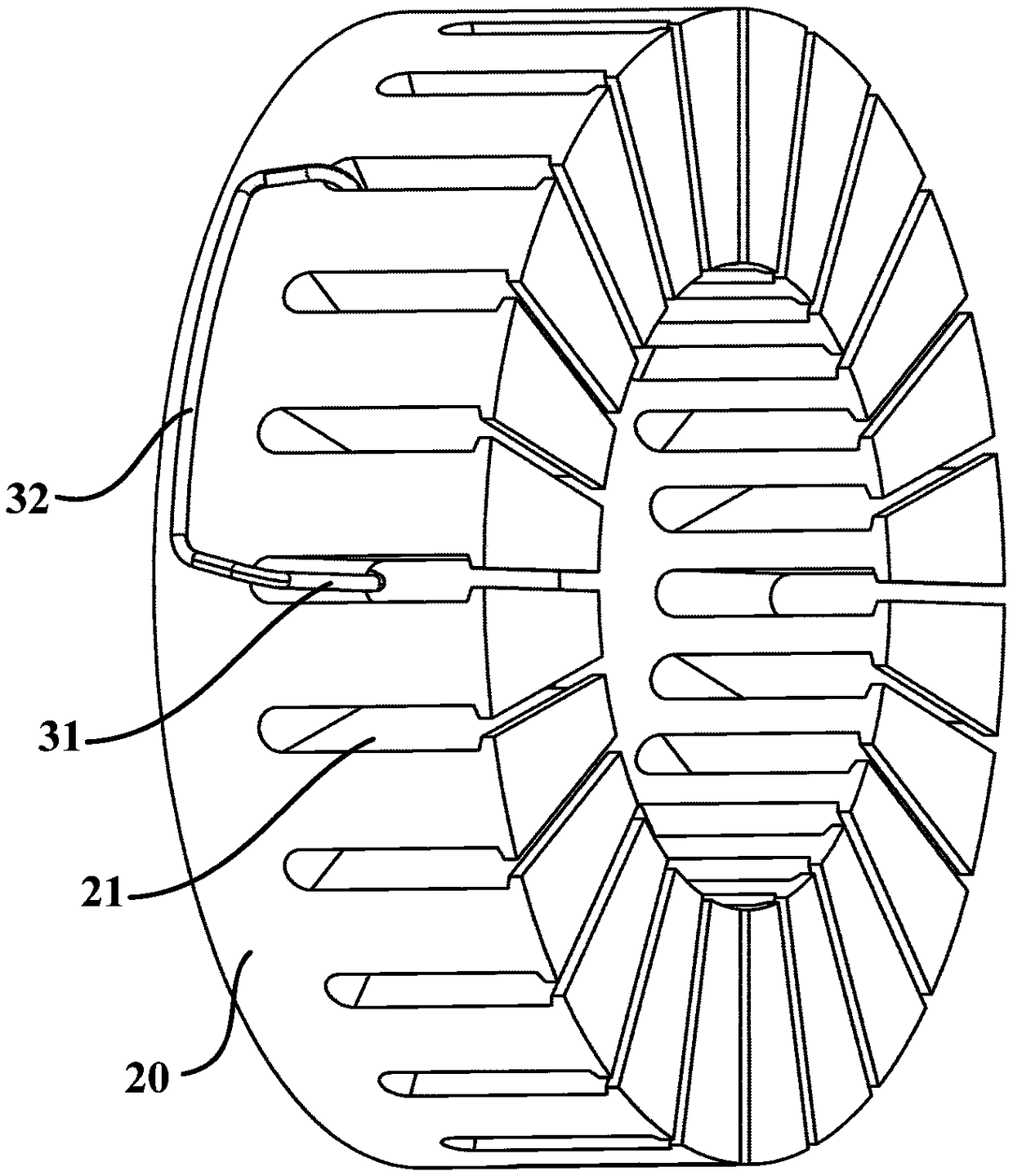

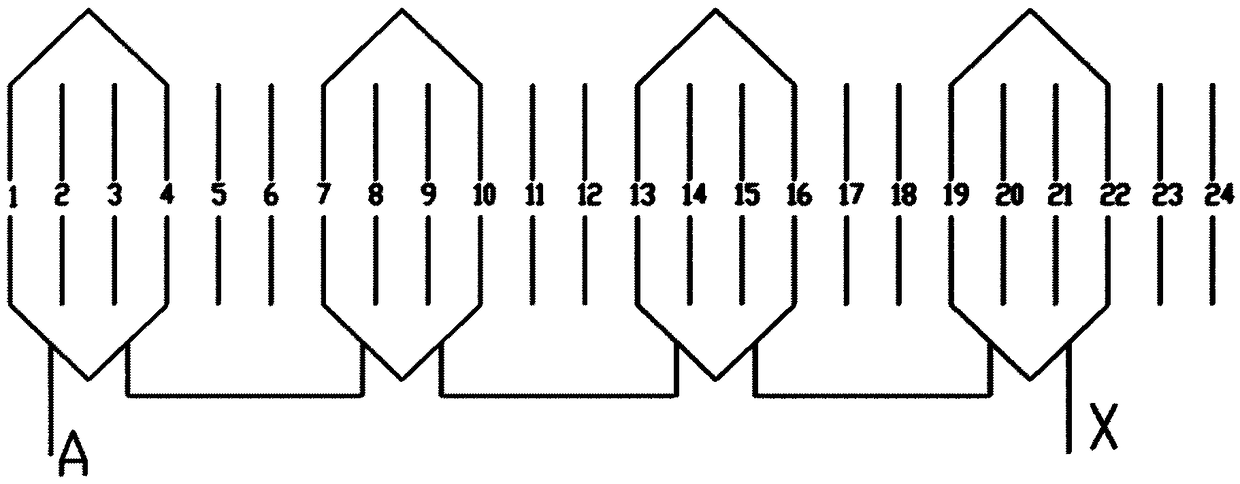

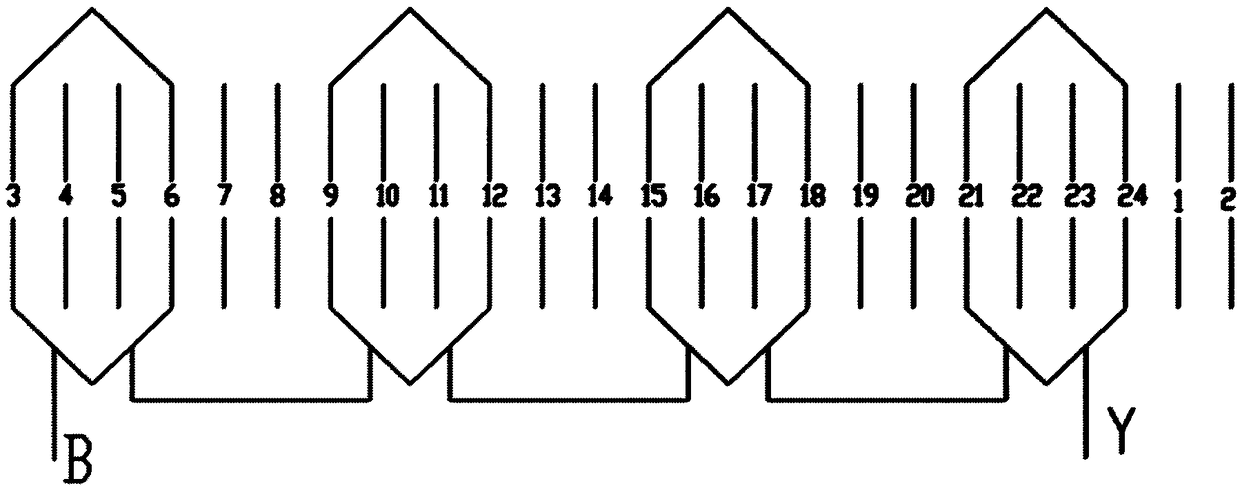

[0023] figure 1 is a schematic structure diagram of the stator winding structure of the axial flux motor according to an embodiment of the present invention. Such as figure 1 shown and refer to Figure 2 to Figure 15 , the embodiment of the present invention provides a stator winding structure of an axial flux motor. The stator winding structure includes a stator core 20 having a plurality of stator slots 21 and a three-phase winding wound on the stator core 20 . In particular, the inner end 33 and / or the outer end 32 of each phase winding is bent toward the yoke of the stator core 20 so that the inner end and / or outer end of the three-phase winding are folded on the yoke. Preferably, the inner end and the outer end of each phase winding are bent towards the yoke of the stator core 20, so that the inner end and / or outer end of the three-phase winding are folded on the yoke.

[0024] After the coil is embedded, the end of the winding is folded toward the yoke of the stator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com