Method for obtaining artificial collagen casing with tender bites and casing obtained by the same

A collagen casing, artificial technology, applied in sausage casings, making sausage casings, slaughtering and other directions, can solve the problem of inconsistent quality of final products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Coils of straight thin collagen casing Colfan JF Caliber 18, commercialized by Viscofan S.A, Spain, were heat treated by applying the technique described below:

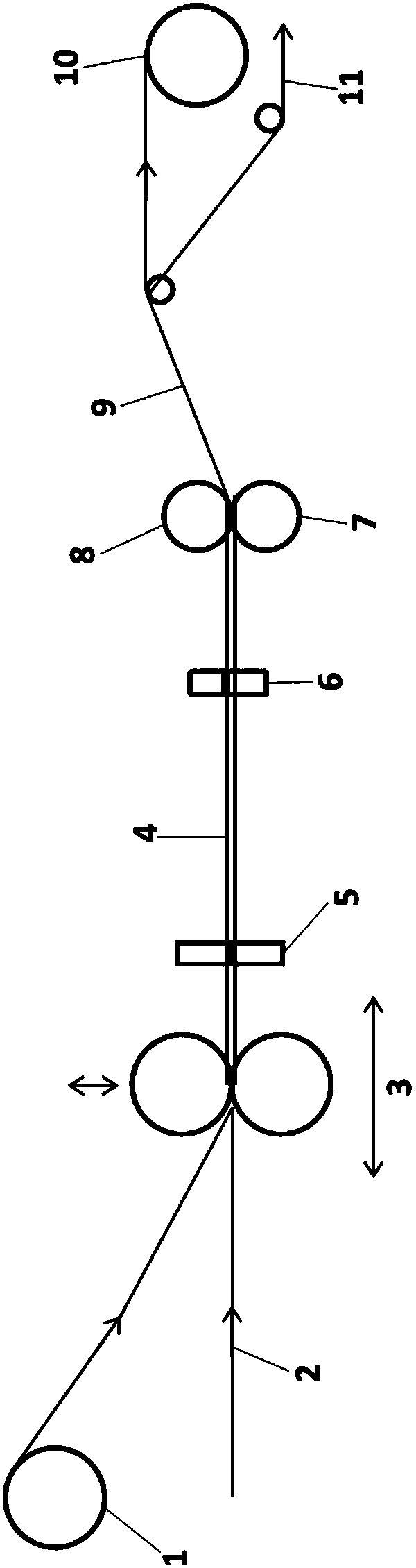

[0048]Non-crosslinked Colfan JF casings are manually unwound, conveyed through pairs of rollers, and further passed through annular air blowers, through pairs of take-up rollers.

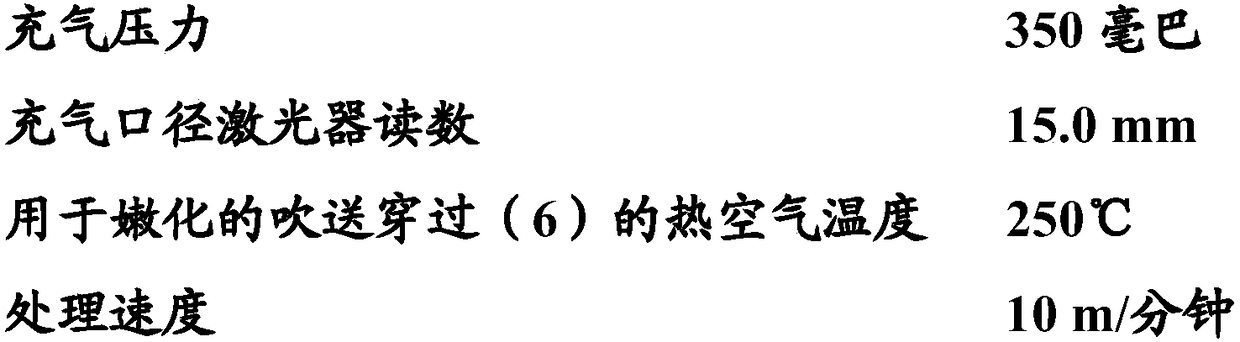

[0049] The casing is aerated to 350 mbar and its air bubbles are trapped between the two pairs of rollers.

[0050] The diameter laser adjusts the desired aerated diameter of the captured casing by moving the platform carrying the pair of conveyor rollers forward and / or backward.

[0051] The conveying roller pair rotates at 13.3 m / min, and the receiving roller pair rotates at 10 m / min. A sufficient flow of heated air is blown annularly through the blower surrounding the aerated casing.

[0052] Thereby, the trapped casing air bubbles heat shrink around the entire casing, which becomes a continuous heat treatment. The heat-treate...

Embodiment 2

[0057] This sample has been treated like sample 1, but with a higher temperature of the air stream blown around the casing.

[0058]

Embodiment 3

[0060] This sample has been treated like sample 1, but with a much higher temperature of the air stream blown around the casing.

[0061]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com