Multifunctional welding rotary table device

A multi-functional, turntable technology, used in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of large motor shaft runout, easy slippage of pulleys, and low torque, and achieve smooth operation, good speed conversion, and large torque. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

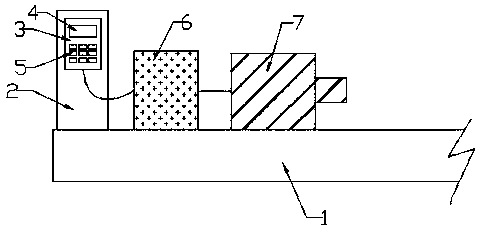

[0015] Such as figure 1 As shown, the present invention provides a kind of multifunctional welding turntable device, comprises conversion table 1 and vector engine 7, and the table top side of conversion table 1 is welded with vertical plate 2, is fixed with electrical switch 3 by bolt on vertical plate 2, electrical switch 3 is also connected to the frequency converter 6 installed on the conversion table 1 through wires, and the frequency converter 6 is connected to the vector motor 7 installed on one side thereof through wires.

[0016] Set the number of rotations and forward and reverse conversion through the button 5 on the electrical switch 3, and display it on the display screen 4. At the same time, the electrical switch 3 transmits the changed data to the frequency converter 6, so that the frequency converter 6 can control the vector engine accordingly. 7. Carry out rotation number and forward and reverse conversion. Improve the problems of large vibration of the motor...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap