Steel mesh adjustable full-automatic printing machine

A fully automatic printing machine technology, applied to screen printing machines, printing machines, rotary printing machines, etc., can solve the problems of reduced precision, waste of time, and inability to guarantee stability and precision, and achieve the effect of high scraping precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

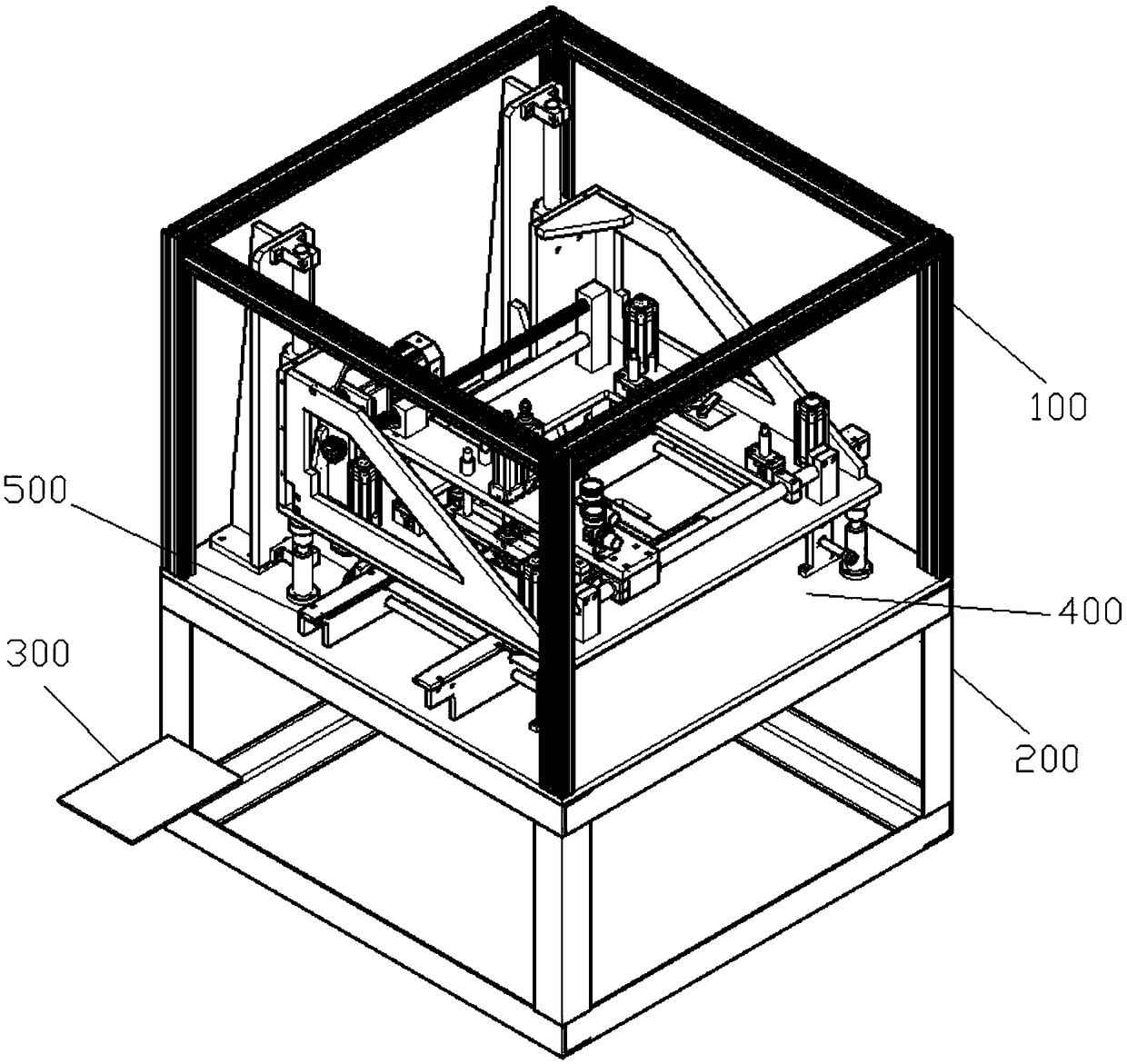

[0033] Such as Figure 1-6 Shown, which shows a specific embodiment of the present invention, such as figure 1 As shown, a steel mesh adjustable automatic printing machine of the present invention includes a lower frame and an upper frame; a working platform is set on the lower frame, and a transmission guide rail for transmitting PCBs is set on the working platform;

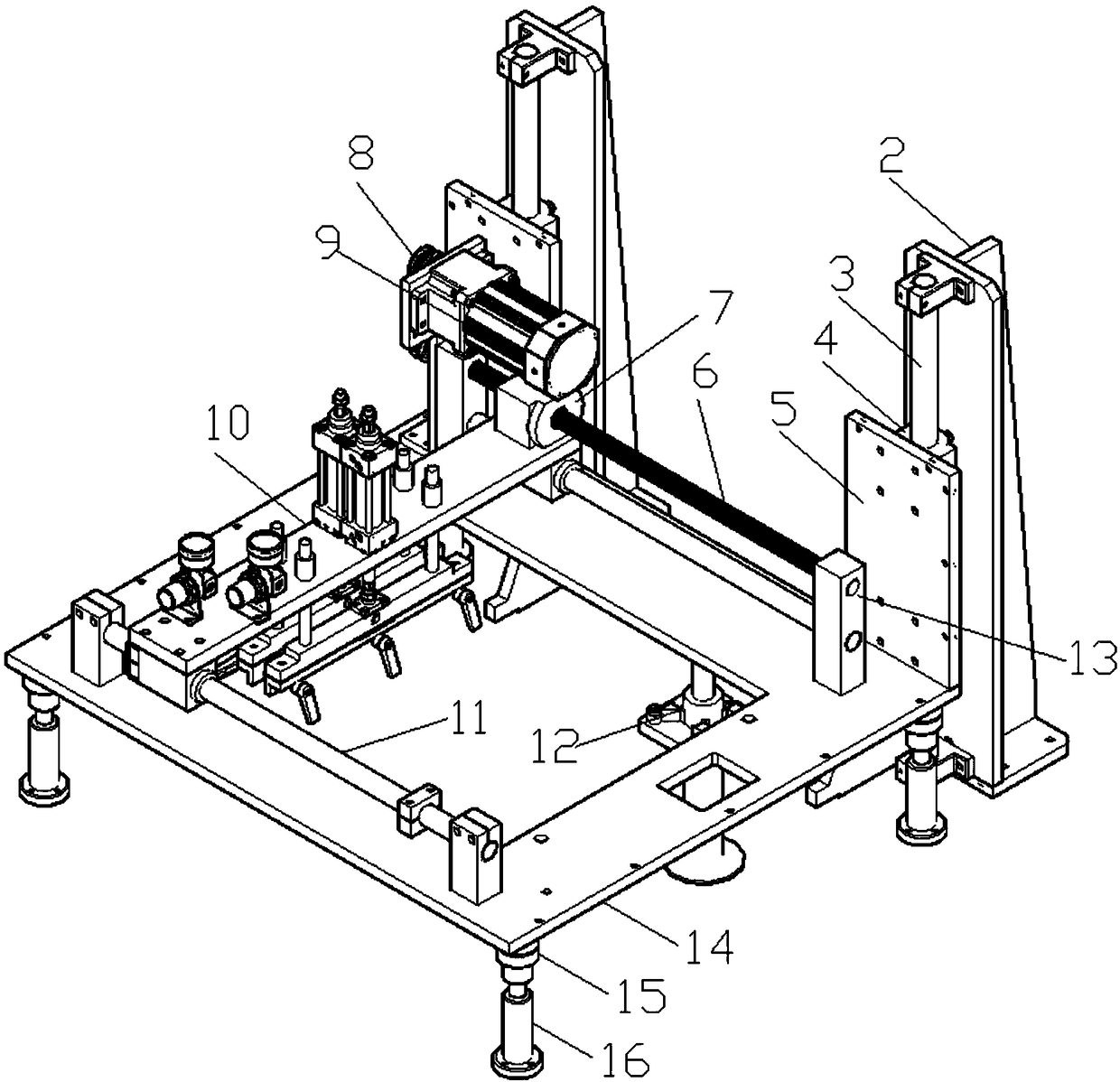

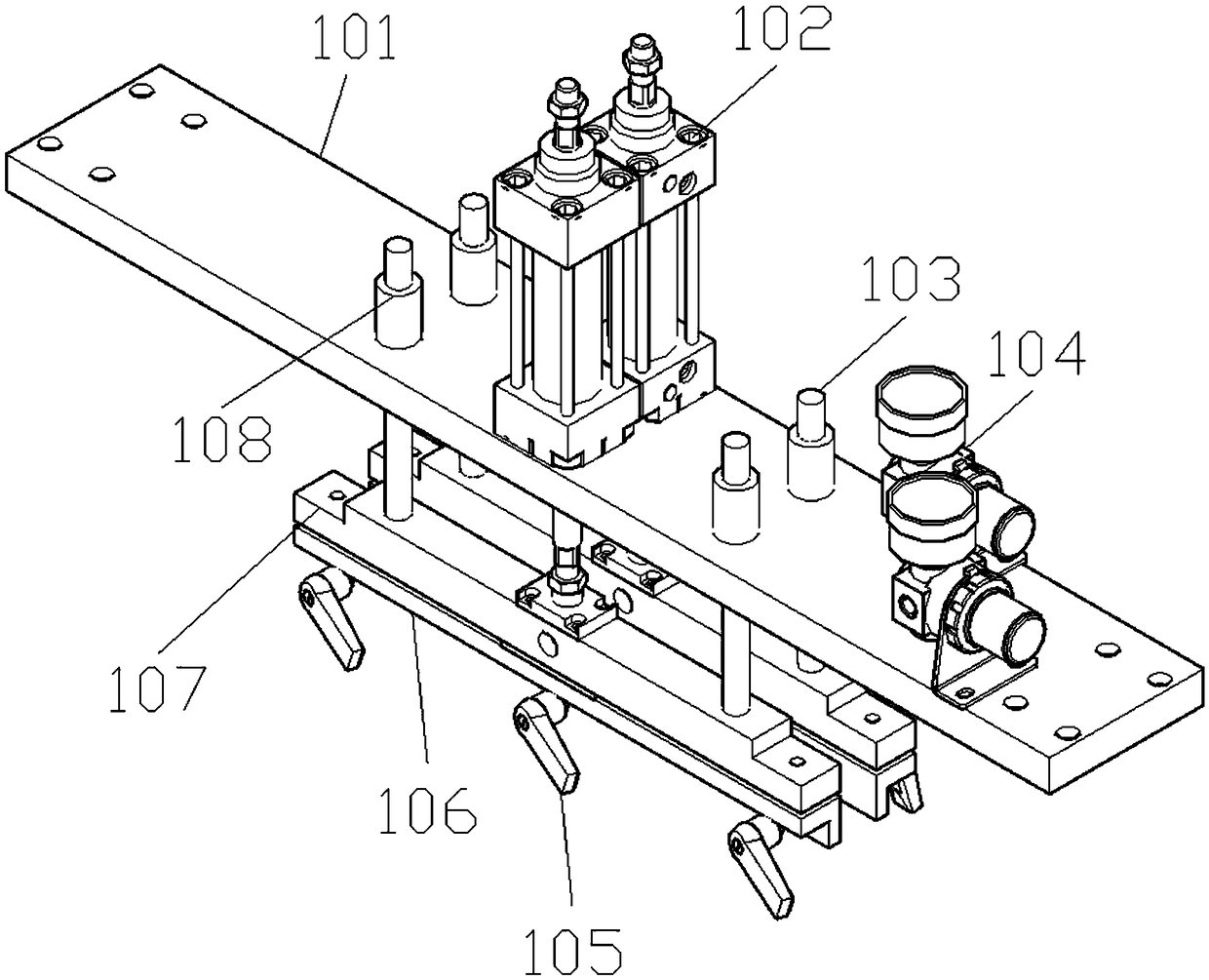

[0034] In the upper frame, a scraper assembly is arranged above the transmission guide rail; the scraper assembly includes two symmetrically arranged vertical supports, each vertical support is equipped with a lifting guide rod, and the lifting guide rod is slid to assemble the lifting slide block, the connecting plate is installed on the lifting slider, and the assembled horizontal plate set in the horizontal direction is fixed on the two connecting plates at the same time. Lead screw, below the traversing lead screw and parallel to the traversing lead screw, there is also a fixedly installed first traversing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com