A method for producing superphosphate by using industrial waste mixed acid

A technology of superphosphate and waste mixed acid, applied in the directions of superphosphate, separation method, combustion method, etc., can solve the problems that large-scale production can not be carried out normally, can not completely eliminate tail gas odor, tail gas odor residue, etc. Significant economic and environmental benefits, expanding utilization channels, and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

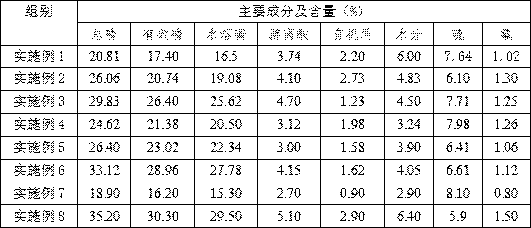

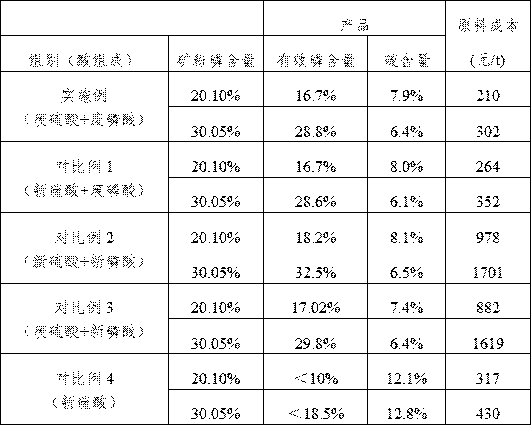

Examples

Embodiment 1

[0044] A method for producing superphosphate by using industrial waste mixed acid, the reaction material is calculated by: waste phosphoric acid P 2 o 5 =45.7%, waste sulfuric acid content=85%, X=20%, mixed acid dosage is 100%, mixed acid concentration is 62%, including the following steps:

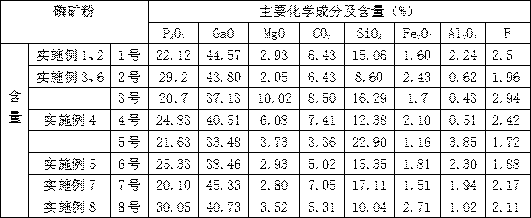

[0045] (1) First turn on the mixer, mixing reactor and the exhaust fan in the chemical formation room, then add 10kg of No. 1 phosphate rock powder, 1.9kg of water and 3.37kg of etching waste phosphoric acid into the mixer and mix them at 52°C Stir and react for 5 minutes to prepare a mixed slurry, and simultaneously use an exhaust fan to introduce waste gas into the waste gas treatment system, and the concentration of the used etching waste phosphoric acid is P 2 o 5 =45.7%; The main chemical composition of No. 1 phosphate rock powder used is as shown in Table 1;

[0046] (2) Slowly add the above mixed slurry, 5.0kg of 85% waste sulfuric acid and 0.15kg of 65% concentrated nitric acid...

Embodiment 2

[0051] A method for producing superphosphate by using industrial waste mixed acid, the reaction material is calculated by: waste phosphoric acid P 2 o 5 =45.7%, waste sulfuric acid content=85%, X=30%, mixed acid dosage is 100%, mixed acid concentration is 64%, including the following steps:

[0052] (1) First turn on the mixer, mixing reactor and the exhaust fan in the chemical formation room, then add 10kg of No. 1 phosphate rock powder, 1.18kg of water and 7.56kg of etching waste phosphoric acid into the mixer, stir and mix them, and heat them at 58°C Mixed slurry was prepared by stirring and reacting for 6min, and the concentration of the used etching waste phosphoric acid was P 2 o 5 =45.7%, and the waste gas is introduced into the waste gas treatment system with an exhaust fan at the same time; the main chemical composition of the No. 1 phosphate rock powder used is shown in Table 1;

[0053] (2) Slowly add the above mixed slurry together with 4.37kg of 85% waste sulfu...

Embodiment 3

[0058] A method for producing superphosphate by using industrial waste mixed acid, the reaction material is calculated by: waste phosphoric acid P 2 o 5 =38.7%, waste sulfuric acid content=85%, X=20%, mixed acid dosage is 100%, mixed acid concentration is 61%, including the following steps:

[0059] (1) First turn on the mixer, mixing reactor and the exhaust fan in the chemical formation room, then add 10kg of No. 2 phosphate rock powder, 1.0kg of water and 7.0kg of waste phosphoric acid into the mixer and stir at 53°C React 8min to make mixed slurry, P in the waste phosphoric acid used 2 o 5 Content is 38.7%; The main chemical composition of used No. 2 phosphate rock powder is as shown in table 1;

[0060] (2) Slowly add the above mixed slurry together with 5.2kg of 85% waste sulfuric acid and 0.18kg of 65% concentrated nitric acid into the mixing reactor and stir, and stir and react at 93°C for 7 minutes to obtain the slurry. Harmful substances are oxidized, decomposed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com