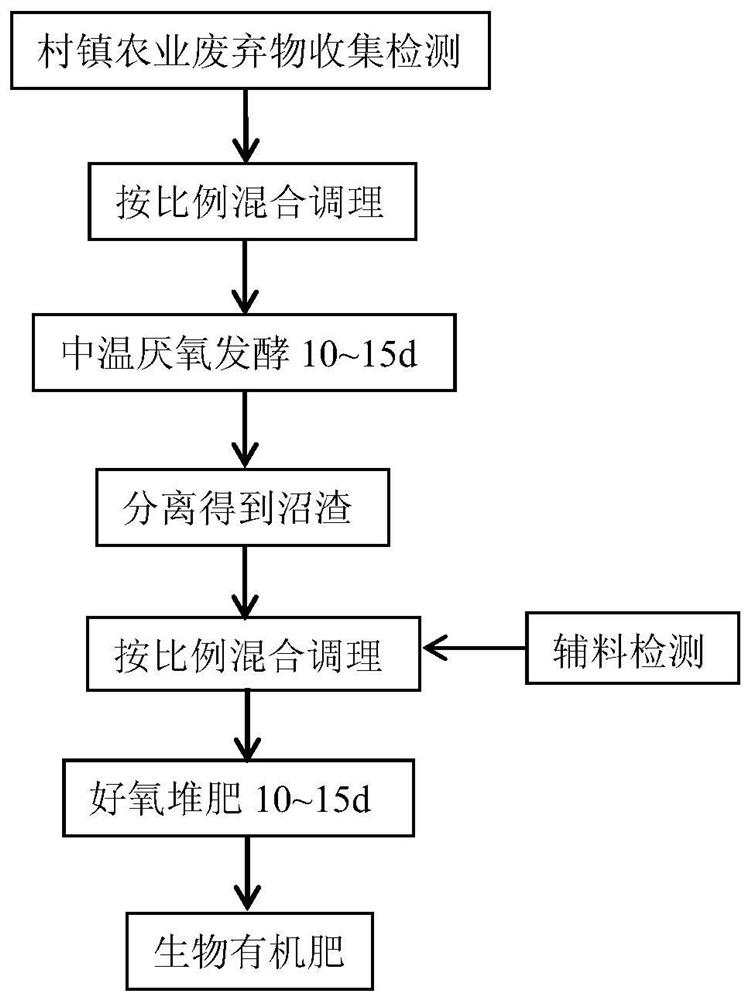

A method for anaerobic-aerobic balanced fermentation of agricultural waste

A technology of agricultural waste and fermentation method, which is applied in the field of rural energy and environmental protection, can solve the problems of long anaerobic fermentation cycle, low nutrient content of biogas fertilizer, and poor efficiency of biogas fertilizer, so as to reduce energy loss, reuse efficiently, save The effect of time cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1: Fermentation is carried out with the cow feces of a cow farm as the research object

[0043] (1) Collect about 20 kg of agricultural waste of this type (mainly feces and litter excreted during cow feeding, but not limited to this), discard impurities such as hair and stones, and add wheat straw to adjust the C / N to 25:1, add anaerobic fermentation tank bottom sludge as an inoculum, the inoculum amount is 30%, adjust the pH value to 7.47, and TS to 10%.

[0044] (2) Put the material into a 50L sequencing batch anaerobic fermentation reactor, after 11 days, the anaerobic fermentation at 38°C reached the peak gas production stage, and collected biogas as domestic gas. The average volumetric gas production rate during the fermentation process was 1.63 m 3 m -3 d -1; The material is separated by a solid-liquid separator to obtain biogas residue and biogas slurry. Among them, the C / N of biogas residue is 19.07, the mass moisture content is 57.18%, and the CO...

Embodiment 2

[0048] Embodiment 2: Taking corn as research object to carry out fermentation

[0049] (1) Collect about 500 kg of agricultural wastes of this type (mainly discarded tail leaves from the growth process of corn and residual straw after harvesting corn), discard impurities such as hair and stones, and add chicken manure to adjust the C / N to 25 : 1, add anaerobic fermentation tank bottom sludge as inoculum, the inoculum size is 40%, the pH value is 7.81, and the TS is 25%.

[0050] (2) Put the material into 1m 3 In the volumetric sequencing batch anaerobic fermentation reactor, after 14d38℃ mesophilic anaerobic fermentation to reach the peak gas production stage, biogas is collected as domestic gas, and the average volumetric gas production rate during the fermentation process is 2.07m 3 m -3 d -1 ; The material is separated by a solid-liquid separator to obtain biogas residue and biogas slurry. Among them, the C / N of biogas residue is 21.7, the mass moisture content is 50.7%...

Embodiment 3

[0054] Embodiment 3: Fermentation is carried out with rural tail vegetables as research object

[0055] (1) Collect about 1 ton of agricultural wastes of this type (mainly the low economic value remaining after the harvest of farmland vegetables, but not limited to this), crush them to a length of 1-3 cm, and add the bottom sludge of the anaerobic fermentation tank as For the inoculum, the inoculation amount is 30%, the C / N value of the adjusted material is 25:1, the pH value is 7.1, and the TS is 10%.

[0056] (2) Put the material into 5m at one time 3 In a biogas digester with a large volume, after 12d38℃ medium temperature anaerobic fermentation to reach the peak stage of gas production, the biogas is collected as domestic gas, and the average volumetric gas production rate during the fermentation process is 1.53m 3 m -3 d -1 ; The material is separated by a solid-liquid separator to obtain biogas residue and biogas slurry. Among them, the C / N of biogas residue is 17.83...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com