A method for preparing cow dung biochar that inhibits nitrogen fertilizer leaching loss

A technology of biochar and cow dung, which is applied in the direction of fertilizer mixture, fertilization device, agricultural gas emission reduction, etc., can solve the problems of no discovery, and achieve the effect of improving utilization efficiency, good economic benefits, and improving soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

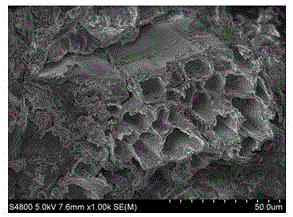

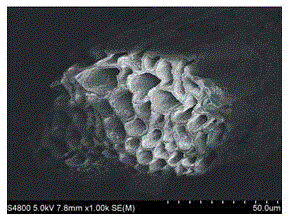

Image

Examples

Embodiment 1

[0026] 1. Pretreatment of cow dung:

[0027] 1.1 Cow dung collection

[0028] Clean the fresh cow dung out of stones and other sundries. Make the amount of impurities in it less than 5%.

[0030] Add 1% quicklime to the collected cow dung and mix thoroughly so that the cow dung will not ferment anaerobically. The cow dung was spread flat on a clean hard cement slab with a thickness of 10 cm, and was naturally air-dried for 6 days under natural ventilation. The moisture content of cow dung is reduced below 20%.

[0031] 2. Preparation of Biochar

[0032] 2.1 Preheating

[0033] The cow dung after the above-mentioned dry treatment is tiled in the tray, and the thickness is 3cm. Put it in an oven and dry it at 95°C for 5 hours, so that the moisture content of cow dung is below 8%.

[0034] 2.2 Pyrolysis of biochar

[0035] Put the above-mentioned preheated cow dung into a crucible-like vessel, put it into a muffle furnace, and then close the...

Embodiment 2

[0042] 1. Pretreatment of cow dung:

[0043] 1.1 Cow dung collection

[0044] Clean the fresh cow dung out of stones and other sundries. Make the amount of impurities in it less than 5%.

[0045] 1.2. Cow dung drying

[0046] Add 1.5% quicklime to the collected cow dung and mix thoroughly so that the cow dung will not be fermented anaerobically. The cow dung was spread on a clean hard cement slab with a thickness of 12cm, and was naturally air-dried for 9 days under natural ventilation. The moisture content of cow dung is reduced below 20%.

[0047] 2. Preparation of Biochar

[0048] 2.1 Preheating

[0049] Spread the cow dung after the above-mentioned dry treatment in the tray with a thickness of 4cm. Put it in an oven and dry it at 100°C for 4 hours, so that the moisture content of cow dung is below 8%.

[0050] 2.2 Pyrolysis of biochar

[0051]Put the above-mentioned preheated cow dung into a crucible-like vessel, put it into a muffle furnace, and then close the mu...

Embodiment 3

[0058] 1. Pretreatment of cow dung:

[0059] 1.1 Cow dung collection

[0060] Clean the fresh cow dung out of stones and other sundries. Make the amount of impurities in it less than 5%.

[0061] 1.2. Cow dung drying

[0062] Add 2% quicklime to the collected cow dung and mix thoroughly so that the cow dung will not ferment anaerobically. The cow dung was spread on a clean hard cement slab with a thickness of 15cm, and was naturally air-dried for 12 days under natural ventilation. The moisture content of cow dung is reduced below 20%.

[0063] 2. Preparation of Biochar

[0064] 2.1 Preheating

[0065] The cow dung after the above-mentioned dry treatment is tiled in the tray, and the thickness is 5cm. Put it in an oven and dry it at 105°C for 3 hours, so that the moisture content of cow dung is below 8%.

[0066] 2.2 Pyrolysis of biochar

[0067] Put the above-mentioned preheated cow dung into a crucible-like vessel, put it into a muffle furnace, and then close the muf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com