Multi-functional short-staple rope twisting machine

A short-fiber and multi-functional technology, which is applied in the field of short-fiber rope punching machines, can solve the problems of inconsistent lengths of twisted ropes, lack of rope retrieval function in storage and storage of unsquare ropes, and easy overflow of fiber hair, etc., and achieves the effect of ensuring consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

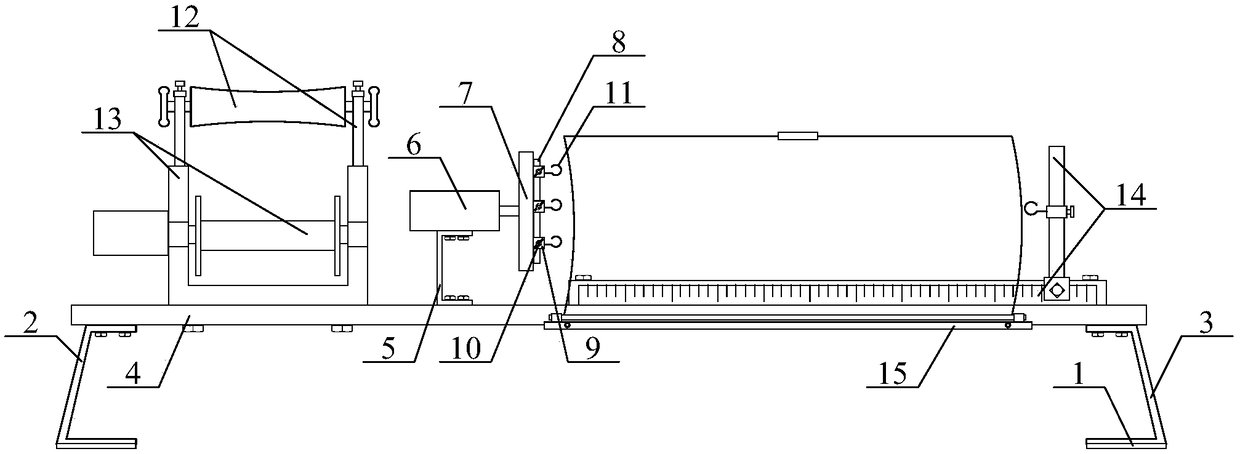

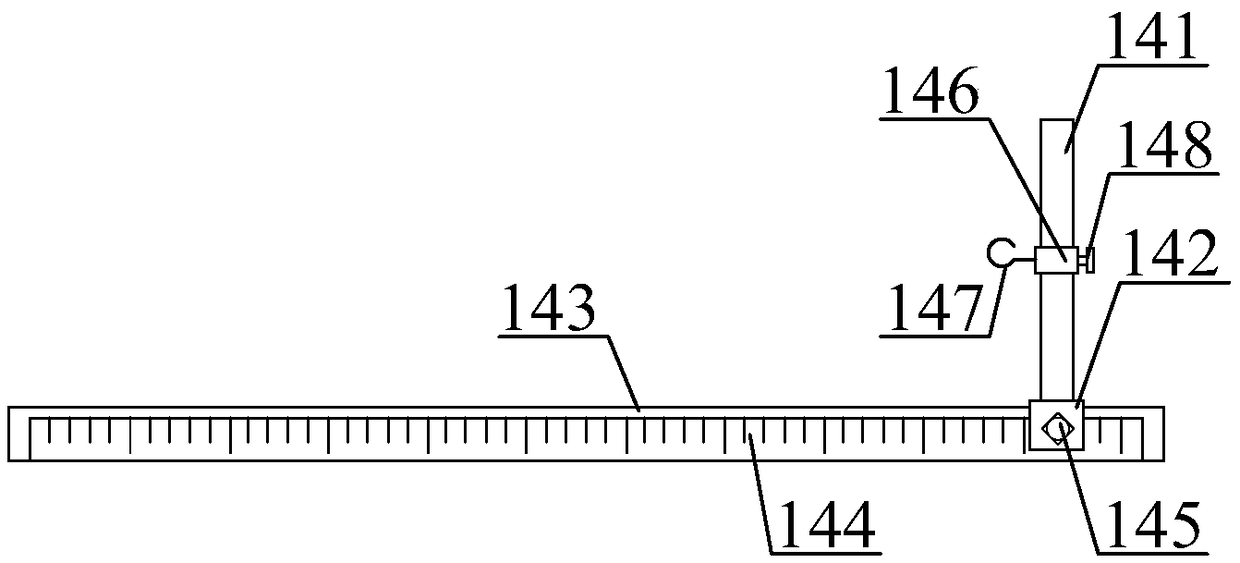

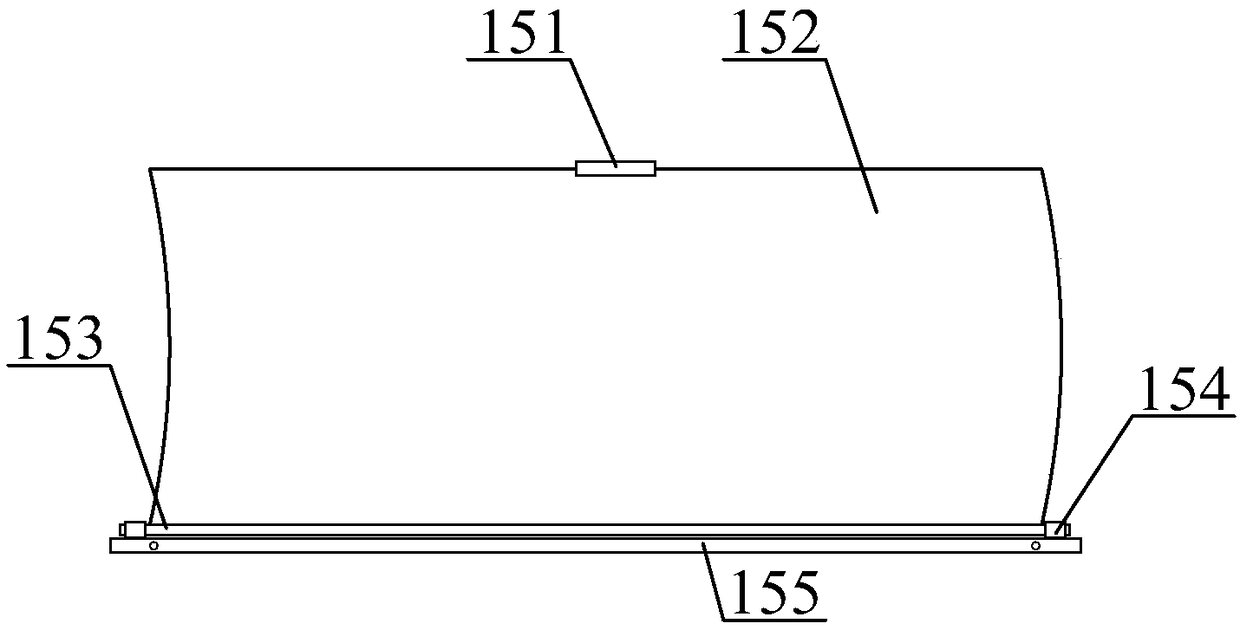

[0049] as attached figure 1 to attach Figure 6 shown

[0050] The present invention provides a multi-functional staple fiber rope-tying machine, which comprises a non-slip mat 1, a left support leg 2, a right support leg 3, a machine base 4, a U-shaped support frame 5, a twisting rope motor 6, a rotating disc 7, Linear slide rail 8, U-shaped slide block 9, thumb screw 10, twisting rope hook 11, rope take-up and replacement wheel structure 12, rope take-up wheel structure 13 after tying the rope, rope length measurement and determination rail structure 14 and anti-spill cover Structure 15, the anti-skid pad 1 is glued laterally on the lower surface of the lower horizontal section of the left support leg 2 and the lower surface of the lower horizontal section of the right support leg 3; The front and rear ends on the left side of the bottom of the base 4; the bolts on the right side of the support leg 3 are respectively installed on the front and rear ends on the right side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com