Volcanic slag railway roadbed and construction method thereof

A railway embankment and volcanic slag technology, which is applied in the field of railway embankment and its construction, can solve the problems of ineffective use of excavated earth, environmental problems, and increased project cost, so as to reduce purchase and transportation costs, maintain compactness for a long time, The effect of enhancing compaction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

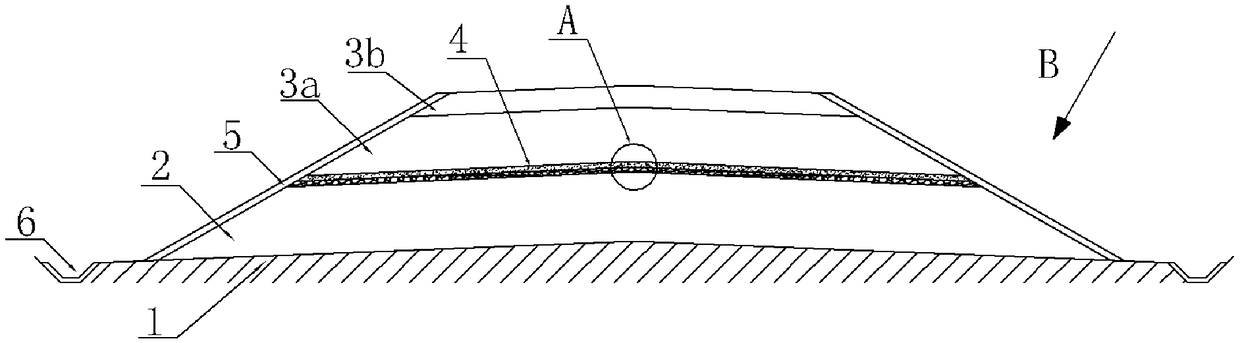

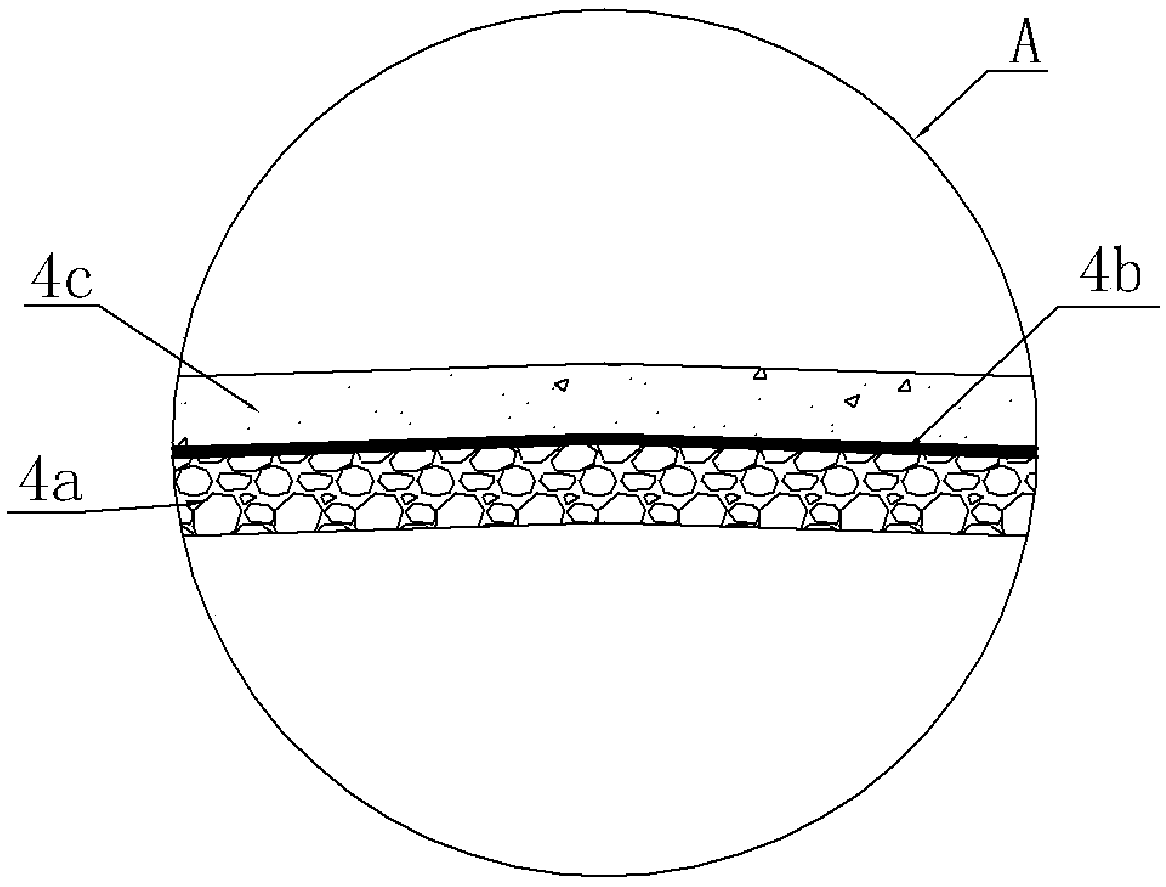

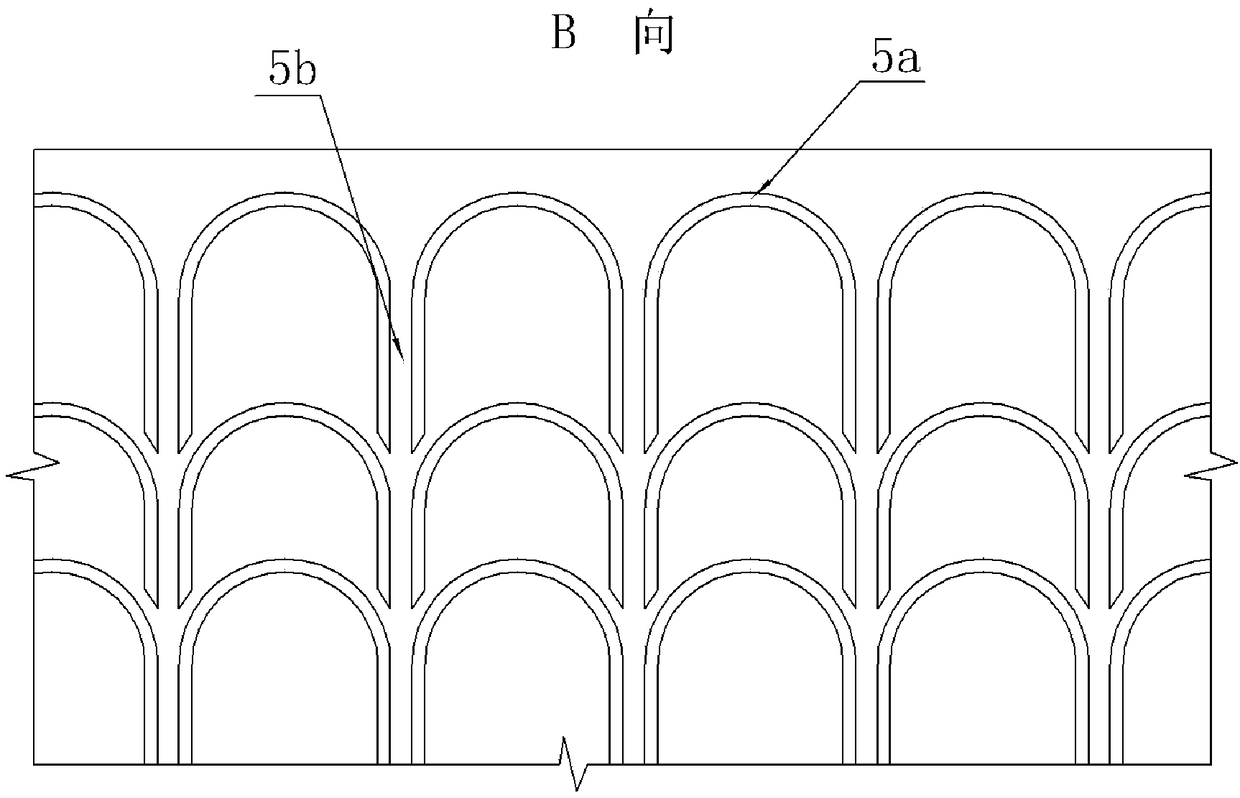

[0032] Figure 1-3 It is shown that a specific embodiment of the present invention is a volcanic slag railway subgrade, which includes a base bed and an embankment 2 below the foundation bed. The embankment 2 is located on the foundation 1. The feature is that the subgrade is made of volcanic slag The embankment 2 is filled with volcanic slag filling, and there is a drainage filter layer 4 between the base bed and the embankment 2; and a slope is provided on the side slope of the roadbed. Surface protection structure 5.

[0033] The construction method of volcanic slag railway subgrade in this example, its steps are:

[0034] A. Foundation treatment

[0035] Compact foundation 1 so that the stability safety factor of foundation 1 is not less than 1.25;

[0036] B. Filling of embankment

[0037] Use volcanic slag filler on foundation 1 to fill embankment 2, and the clearance ratio of embankment 2 is n j ≤32%, foundation coefficient K 30 ≥90MPa / m;

[0038] C. Laying of drainage filter

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Maximum particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com