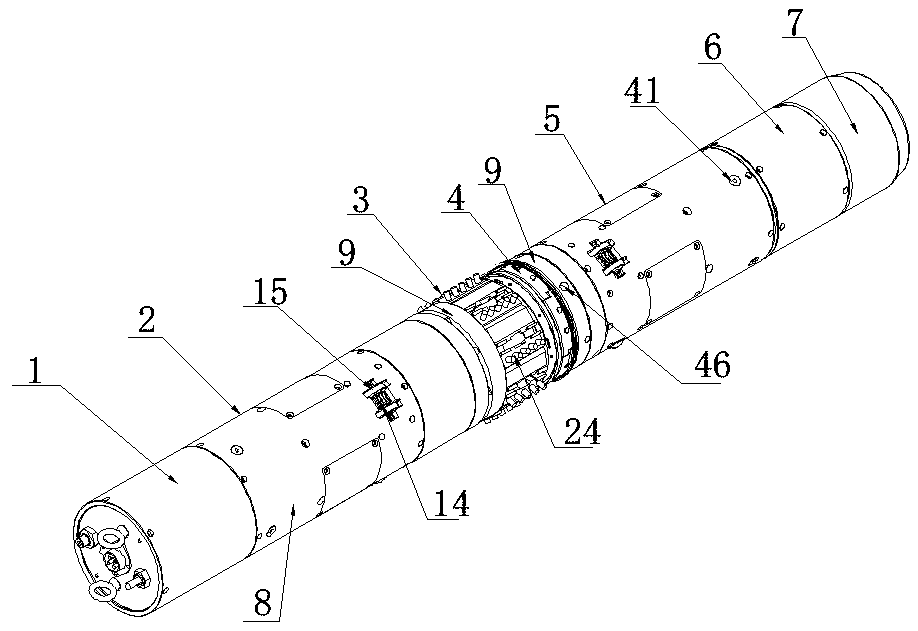

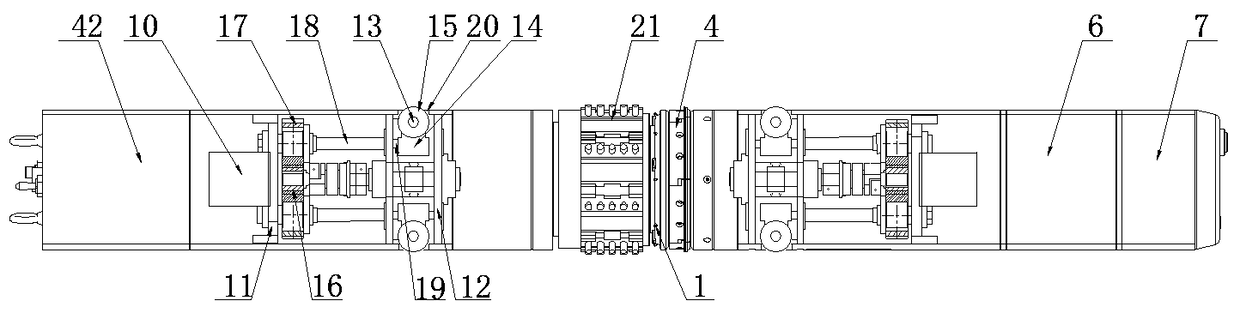

Gun barrel cleaning robot

A technology for cleaning robots and cleaning mechanisms, used in weapon accessories, weapon cleaning devices, offensive equipment, etc., can solve the problems of incomplete cleaning, heavy labor, and inability to remove gunpowder residues, achieving thorough cleaning effects and light labor. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

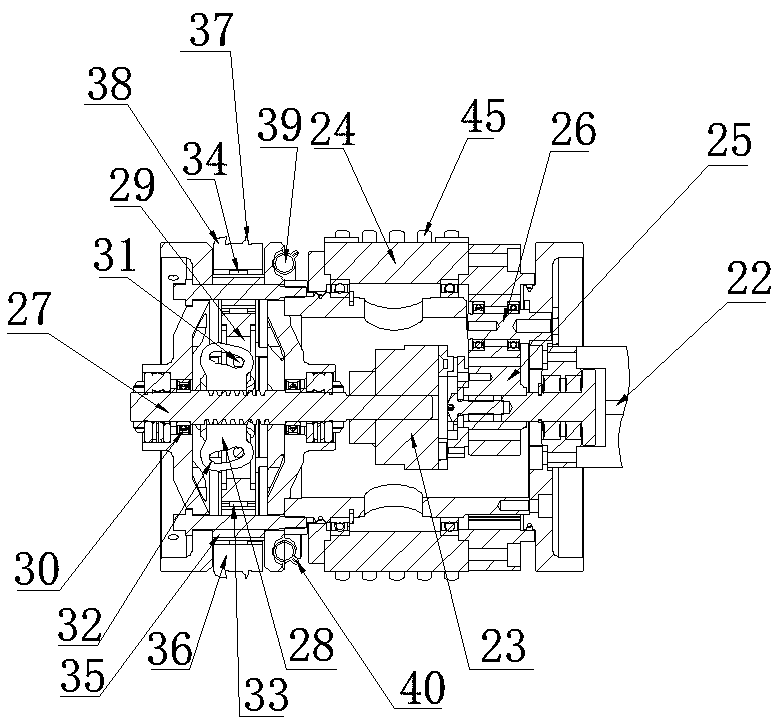

[0033] Such as Figure 5 As shown, the present embodiment one is suitable for the cleaning of smoothbore gun barrels. Each slag scraper 36 is in the shape of a Z-shaped arc, and six slag scrapers 36 are connected end to end, and the outer wall of each slag scraper 36 is provided with a The slag scraping boss 37 and the second slag scraping boss 38, the shape of the first slag scraping boss 37 and the second slag scraping boss 38 are also arc-shaped, and they are tightly fixed on the outer wall of the slag scraping plate 36, When the electromagnetic clutch 23 is closed, the rotating shaft falls off from the driven shaft of the electromagnetic clutch, and the guide shaft slides to the other end in the chute of the cam nut, driving the cam to move and under the elastic force of the compression spring, the fixed plate 35 and the scraper The slag plate 36 stretches out, and the slag scraping plate 36 is connected end to end, and the primary slag scraping boss 37 and the secondary s...

Embodiment 2

[0035] Such as Figure 6 As shown, the second embodiment is suitable for the cleaning of rifled gun barrels. Each slag scraper 36 is in the shape of a zigzag arc, and six slag scrapers 36 are connected end to end. The outer wall of each slag scraper 36 is provided with The arc-shaped slag-scraping bar group composed of a plurality of columnar slag-scraping bars 47, the arc-shaped slag-scraping bar group on the six slag-scraping plates 36 constitute a complete circular slag-scraping bar group, and the columnar slag-scraping bar 47 is used for cleaning Residue between adjacent rifling lines; several slag bumps 48 are also arranged on the outer wall of each of the slag scrapers 36, and the slag scraper bumps 48 on the six slag scrapers 36 form a complete circle, scraping The slag bump corresponds to each rifling, and the slag scraping block is used to clean the residue on the rifling, and the number of the slag scraping bump 48 is set according to the number of the rifled gun rif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com