Pipeline flange screw hole positioning and measurement device

A measuring device and hole positioning technology, which is used in measuring devices, active optical measuring devices, measuring instruments, etc., can solve the problems of inconvenient positioning and measurement of pipeline flange screw holes, affecting positioning measurement accuracy, and project engineering quality threats, etc. Simple, low cost, easy to measure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

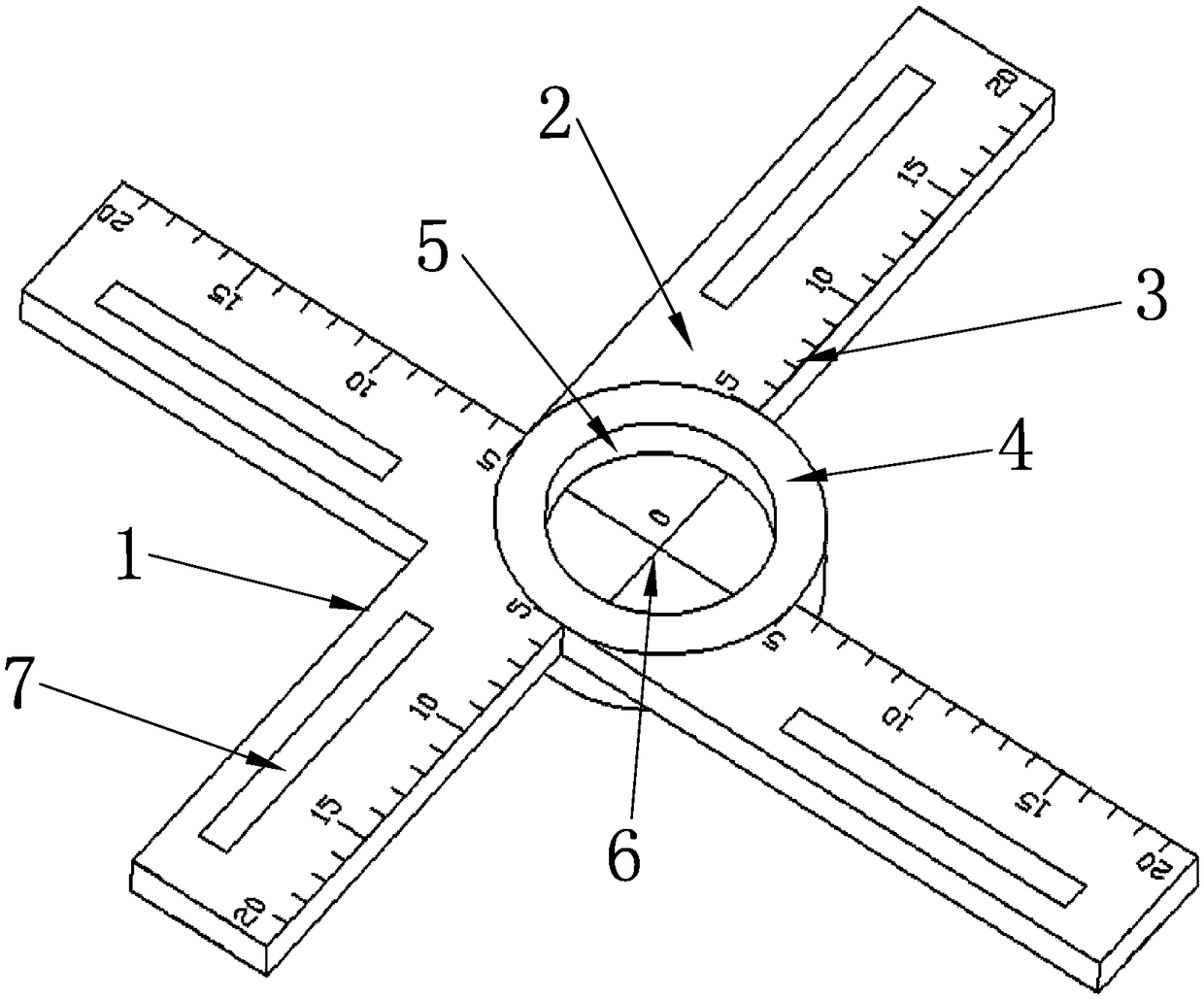

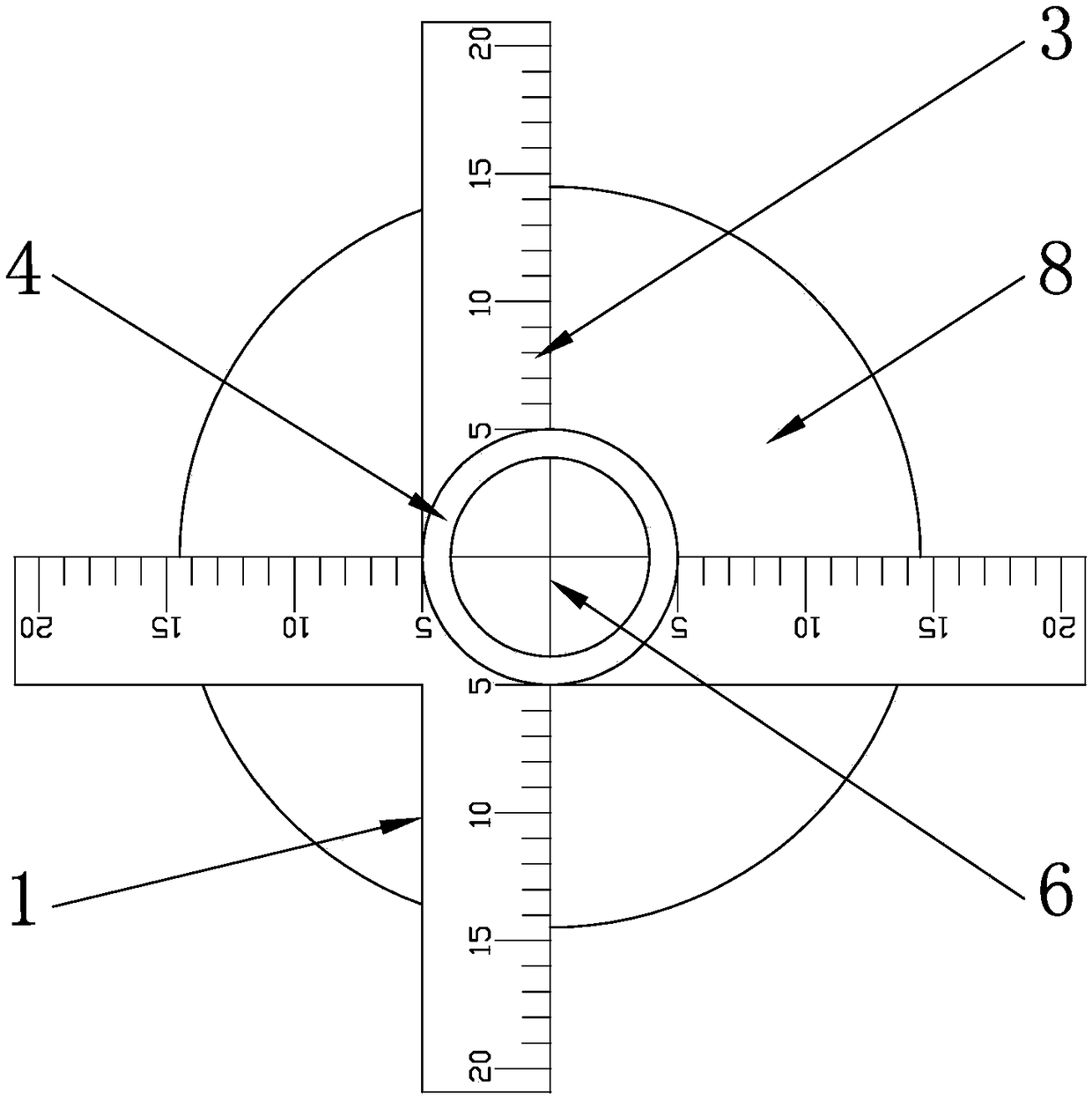

[0021] see figure 1 , a pipeline flange screw hole positioning and measuring device of the present invention, comprising a positioning ruler 1, the positioning ruler 1 is provided with four divergent ends 2, and the positioning ruler 1 is in the shape of a cross, and the upper surface of the positioning ruler 1 is along the Each diverging end 2 is provided with a coordinate line 3, the scales of all the coordinate lines 3 are consistent, and the origins of all the coordinate lines 3 coincide, and the upper surface of all the diverging ends 2 is provided with a magnet 7 on one side of the coordinate line 3, and the The positioning ruler 1 can be adsorbed on the surface of the iron flange.

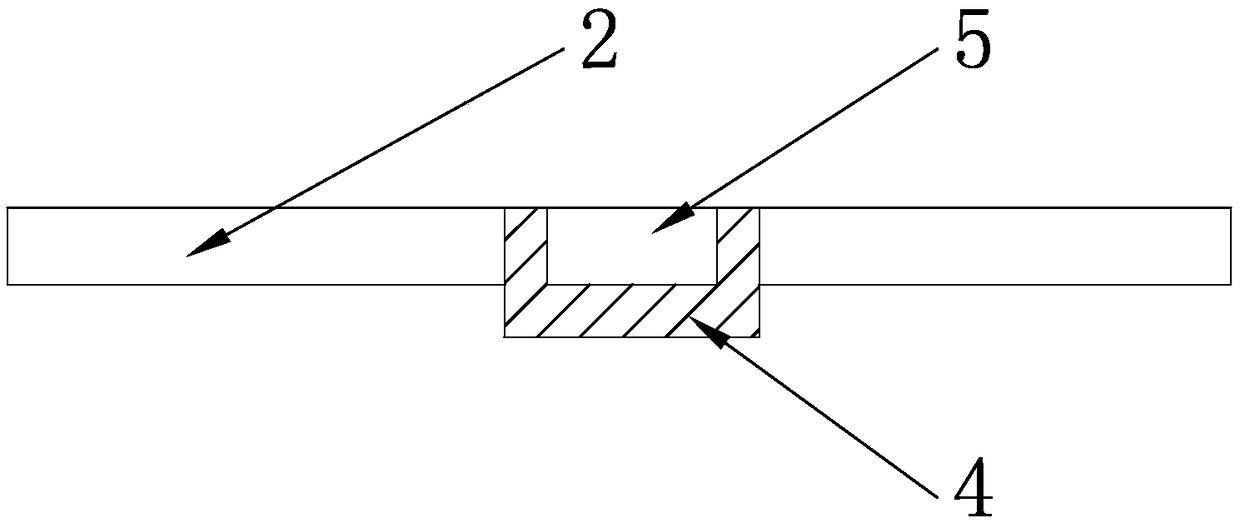

[0022] see further figure 2 , the positioning ruler 1 is also provided with a cylinder 4, the cylinder 4 is a cylinder, the lower end of the cylinder 4 protrudes from the lower surface of the positioning ruler 1, and the upper surface of the cylinder 4 is in contact with the positioning ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com