Sampling device for cutting copper-clad fiberglass sheets

A glass fiber board and sampling device technology, applied in the direction of sampling devices, etc., can solve the problems of low cutting efficiency, troublesome operation, injury to hands, etc., and achieve the effect of eliminating safety hazards and simple and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] At present, in the circuit board production process, it is necessary to perform board removal and grinding operations after drilling, and then sample inspection of the circuit board is required before shipment. The inspection items include surface copper thickness, hole copper thickness, and hole wall roughness and more. When the test fails, the circuit board will be re-drilled, and when the test is passed, it will be shipped. At present, in the sampling inspection, the circuit board is often cut manually, and a circuit board sample of a specified size is cut out for inspection. Not only is the operation troublesome, the cutting efficiency is low, and it may hurt the hands, there is a certain degree of safety. Hidden danger.

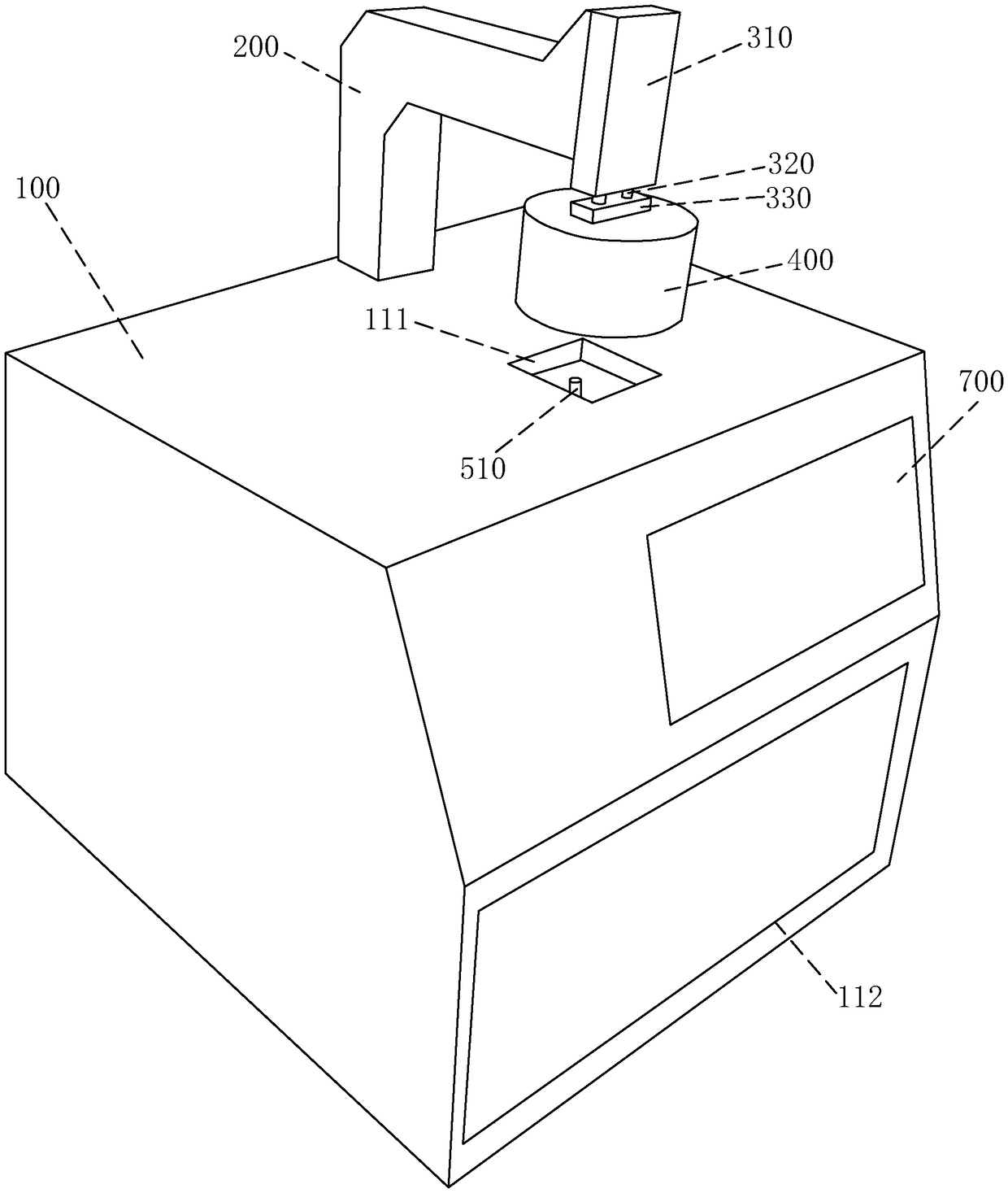

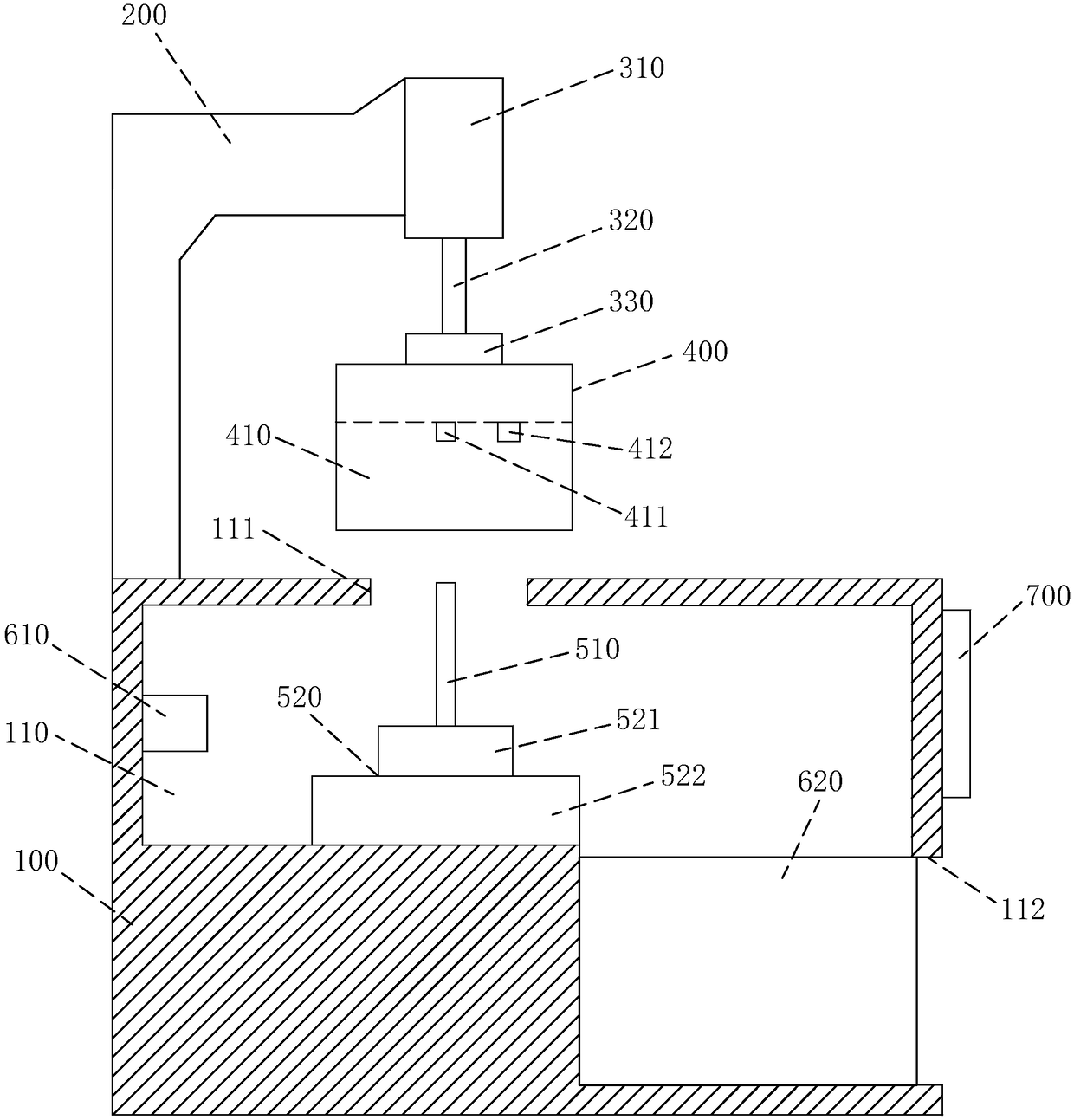

[0021] Based on the above, refer to Figure 1-Figure 2 , an embodiment of the present invention provides a sampling device for cutting copper-clad glass fiber boards, including an operating table 100, a frame 200, a cylinder 310, a push rod 320,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com