Energy-saving environmental-protection water oil separating pipeline

A water-oil separation, energy-saving and environmental-friendly technology, applied in the direction of liquid separation, separation methods, chemical instruments and methods, etc., can solve the problems of inability to use electric valves, inaccurate judgment, manual on-duty, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

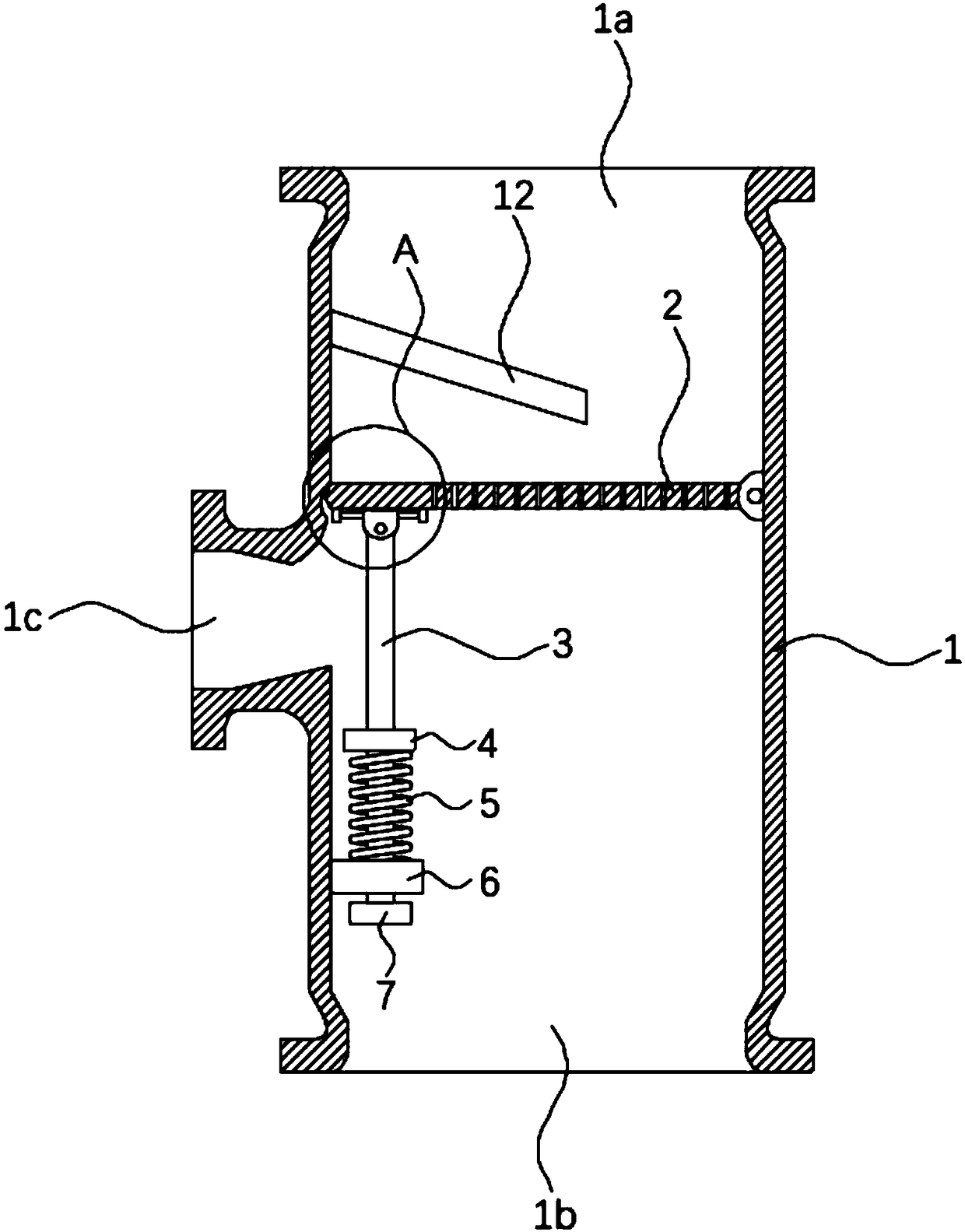

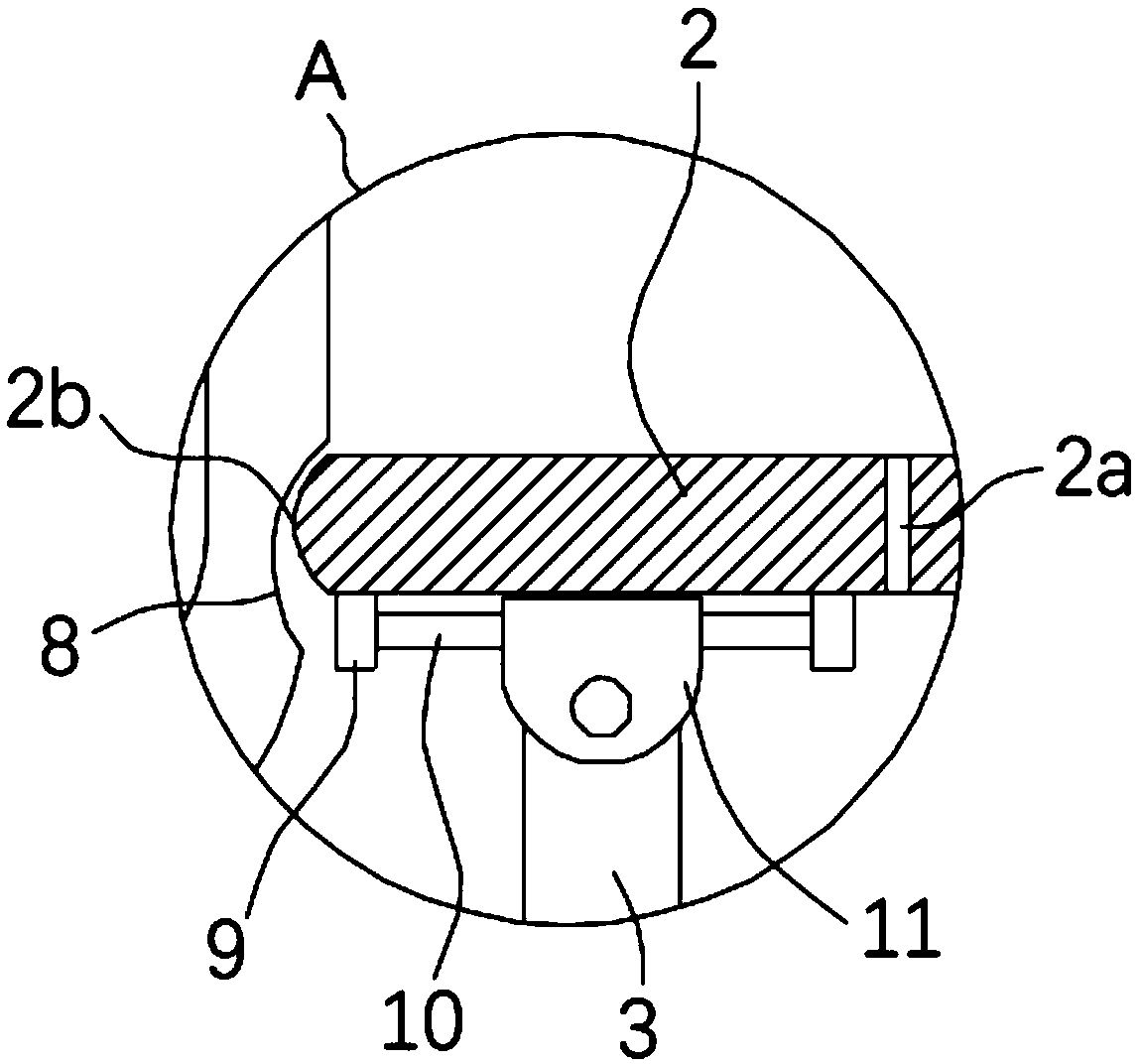

[0021] refer to Figures 1 to 2 , an energy-saving and environment-friendly water-oil separation pipeline, comprising a pipeline 1, two symmetrically arranged ports of the pipeline 1 are respectively defined as a mixed liquid inlet 1a and a water outlet 1b, an opening is opened in the middle of the pipeline 1, and is located in the middle of the pipeline 1 The opening is defined as the oil outlet 1c, and the side of the pipe 1 close to the mixing liquid inlet 1a is provided with an oil baffle 2 that separates oil but not water.

[0022] Specifically, the oil baffle 2 is provided with a plurality of micropores 2a, and the diameter of the micropores 2a can be appropriately increased or decreased according to the capacity of the static container and the diameter of the pipeline 1, thereby improving drainage efficiency, because the micropores 2a so that water can pass through the micropore 2a and be further discharged through the water outlet 1b, but due to the viscosity and surfa...

Embodiment 2

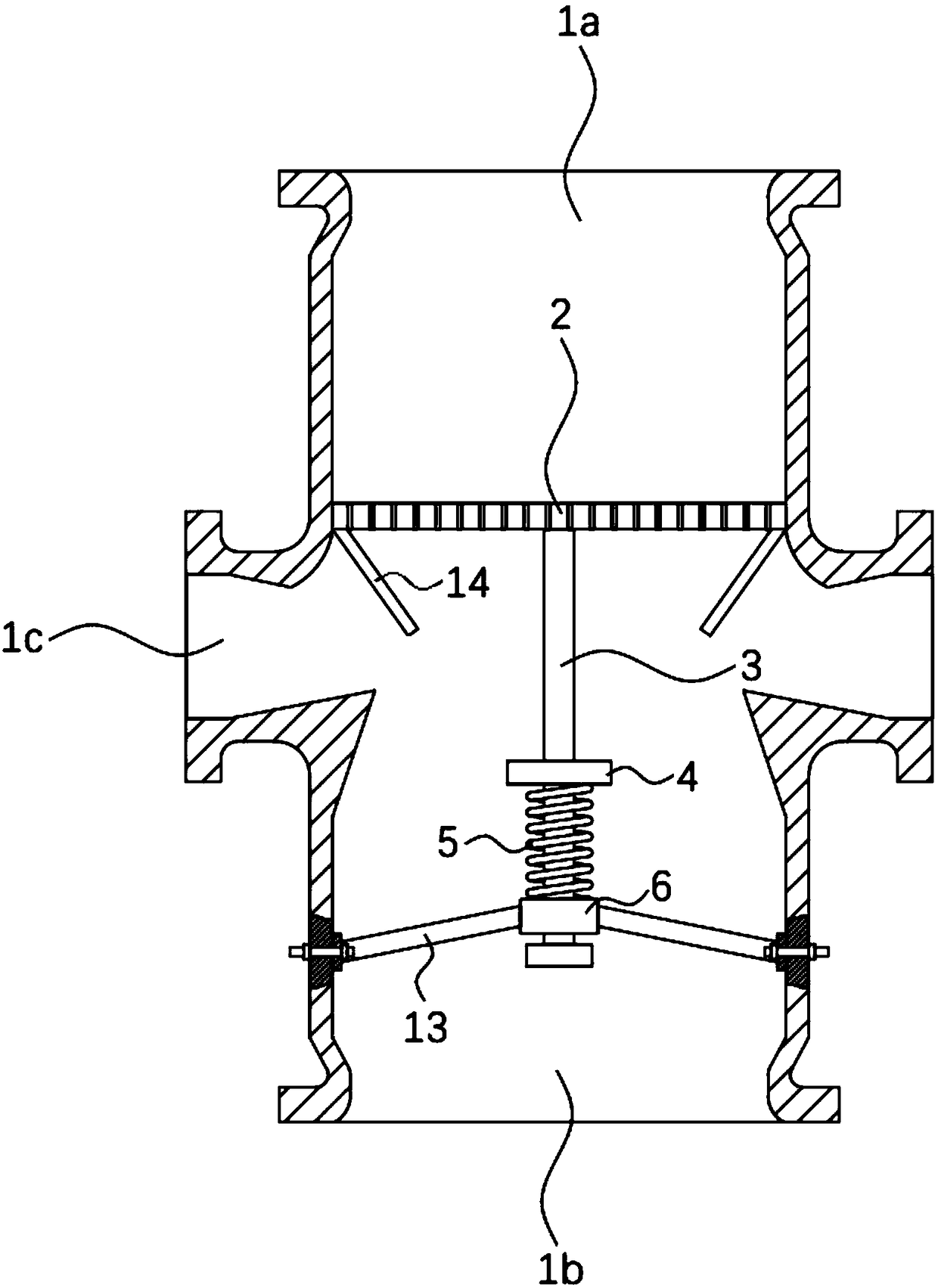

[0034] refer to image 3 , the difference between Embodiment 2 and Embodiment 1 is that the number of oil outlets 1c is two or more, thereby increasing the oil discharge efficiency, and the installation method of the oil baffle 2 and the elastic top part also depends on the number of oil outlets 1c The specific connection method is as follows:

[0035] The middle part of the bottom end of the oil baffle plate 2 is fixedly connected with the connecting rod 3, and the outer surface of the fixed block 6 is fixedly connected with a plurality of obliquely arranged reinforcing rods 13 equidistantly in the circumferential direction. The setting of the reinforcing rods 13 plays a supporting and fixing role. The end of the reinforcement rod 13 away from the fixed block 6 is fixedly connected to the inner wall of the pipe 1 .

[0036] In the embodiment, a confluence plate 14 can be arranged at the bottom end of the oil baffle plate 2, such as image 3 As shown, thereby preventing wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com