Sectional chock-flow type pipeline self-sealing valve

A pipeline and choke technology, applied in the field of segmented choke pipeline self-sealing valves, can solve the problems of equipment and ground pollution, medium discharge, complicated installation methods, etc., to avoid a large amount of leakage and outflow, and to achieve the effect of convenience, speed and installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

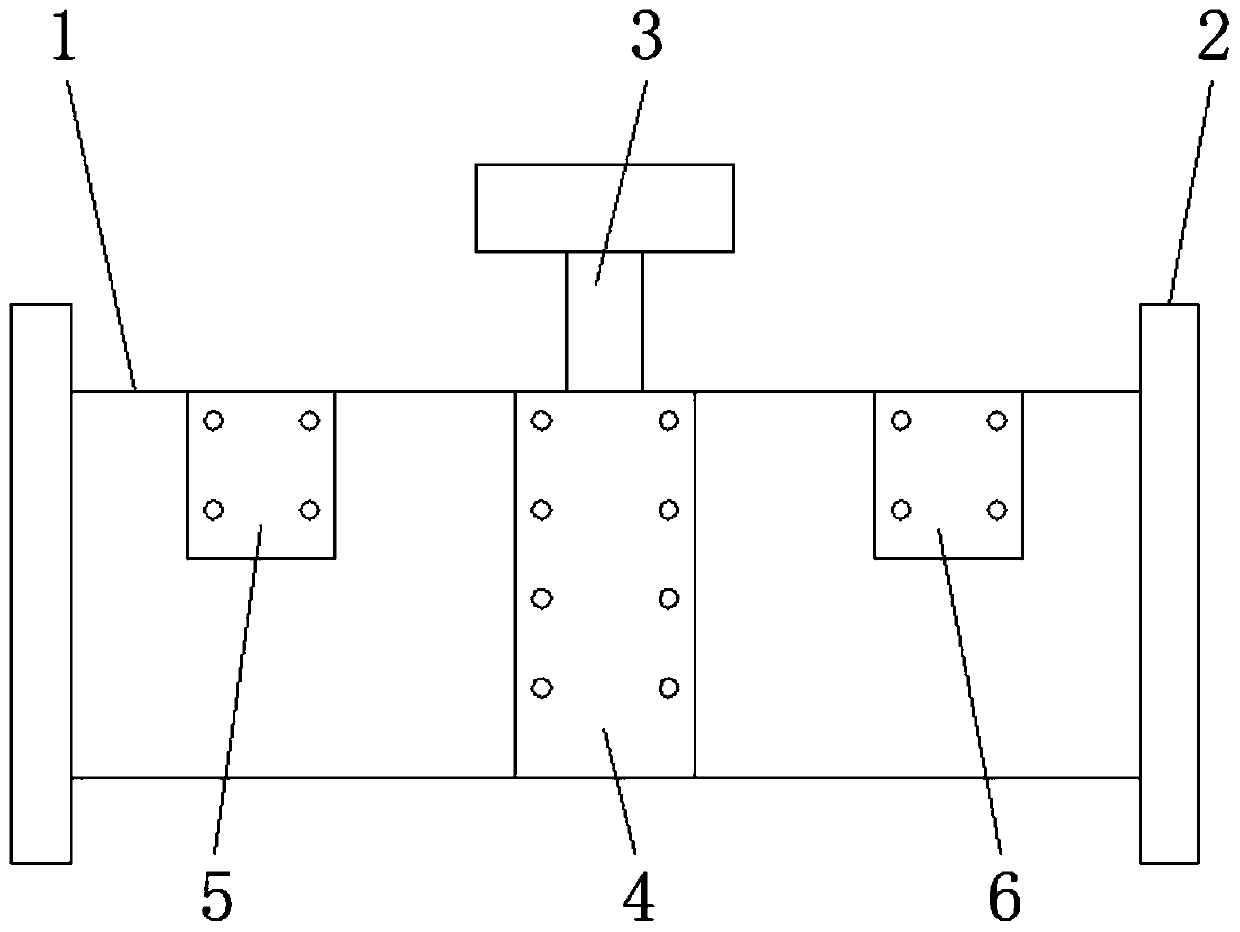

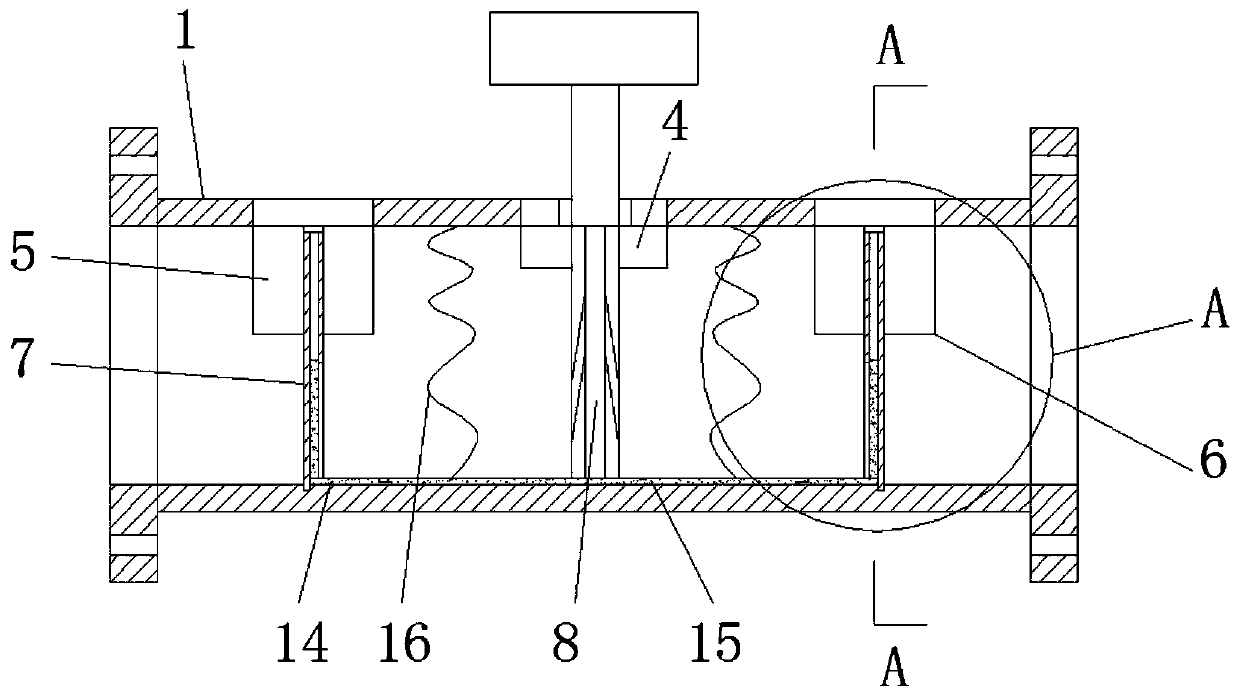

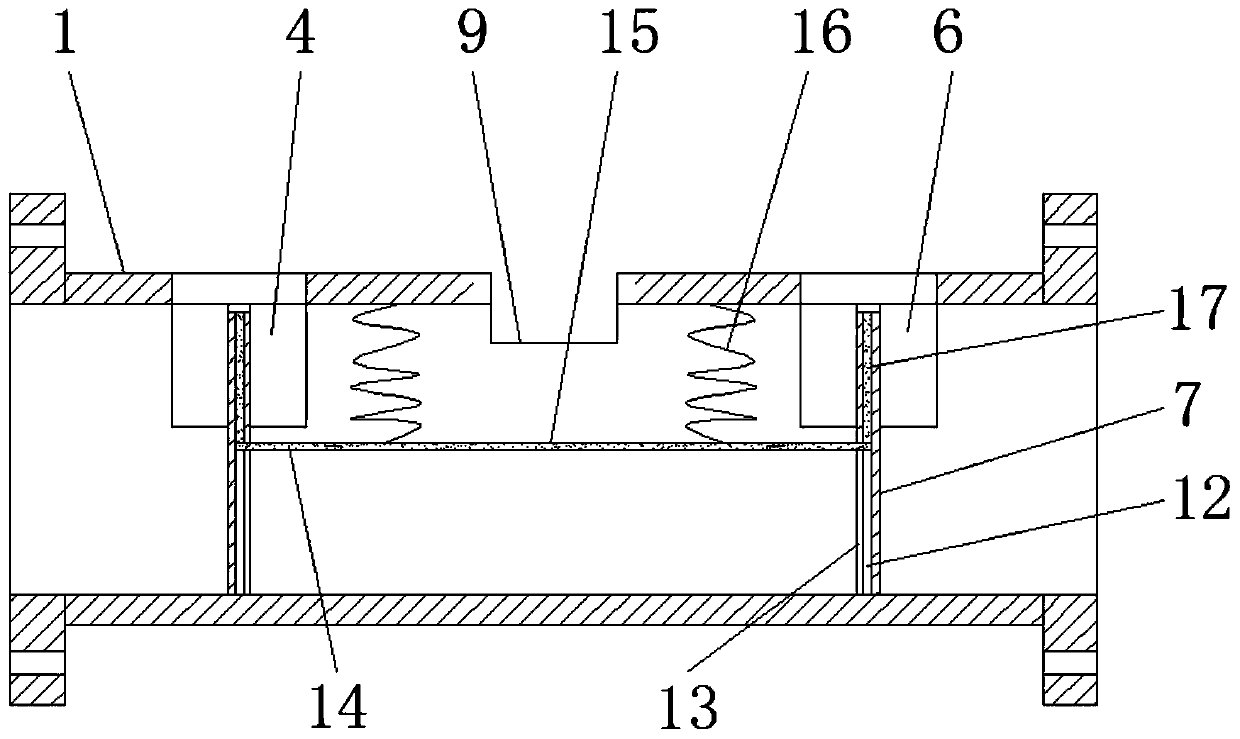

[0029] see Figure 1-9 , the present invention provides a technical solution: a segmented blocking type pipeline self-sealing valve, valve body 1, flange plate 2, valve stem 3, first sealing plate 4, second sealing plate 5, third sealing plate 6 , spoiler 7, valve plate 8, first installation port 9, second installation port 10, third installation port 11, sliding groove 12, sliding port 13, connecting rod 14, linkage rod 15, return spring 16, seal Plate 17, top sealing block 18, first sealing ring 19, second sealing ring 20, sealing groove 21, installation groove 22 and water outlet 23, flanges 2 are welded on both sides of valve main body 1, and valve main body 1 There is a first installation port 9 in the middle part of the center, and the second installatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com