Composite packaging adhesive film and preparation method and application thereof

A technology for encapsulating adhesive films and ionic polymers, applied in applications, other household appliances, chemical instruments and methods, etc., to achieve the effect of improving the anti-PID effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

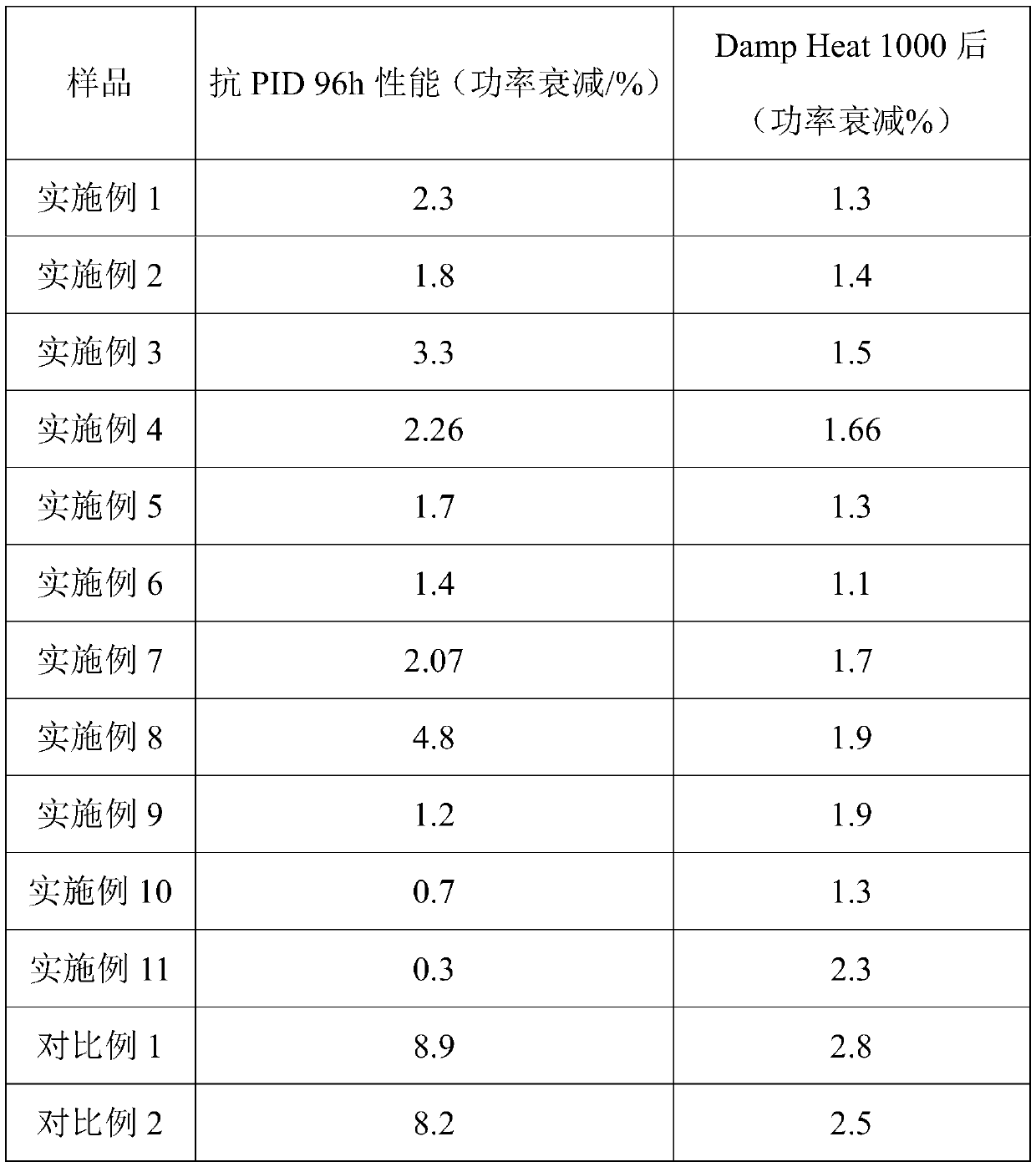

Examples

Embodiment 1

[0063] This embodiment provides a composite packaging adhesive film and a preparation method thereof.

[0064] Wherein, the composite packaging adhesive film includes a core layer and a first skin layer.

[0065] The total mass of the core layer is 100g, including the following components: Surlyn resin 100g.

[0066] The total mass of the first skin layer is 100g, including the following components: EVA resin 98.2g, tert-butyl peroxy-2-ethylhexyl carbonate (crosslinking agent) 0.5g, trimethylolpropane trimethyl Methyl acrylate (crosslinking agent) 0.6g, 3-methacryloxypropyltrimethoxysilane (coupling agent) 0.5g, bis(2,2,6,6-tetramethyl-4- Piperidinyl) sebacate (anti-aging additive) 0.2g.

[0067] Preparation:

[0068] Firstly, the components of the first skin layer are mixed, and then co-extruded with the components of the core layer at 90°C, and then the obtained co-extruded product is embossed, cooled, drawn and rolled to obtain the described Composite encapsulation adhe...

Embodiment 2

[0070] This embodiment provides a composite packaging adhesive film and a preparation method thereof.

[0071] Wherein, the composite packaging adhesive film includes a core layer and a first skin layer.

[0072] The total mass of the core layer is 100g, including the following components: PRIMACOR TM 10 resin 100g.

[0073] The total mass of the first skin layer is 100g, including the following components: POE resin 98.2g, tert-butyl peroxy-2-ethylhexyl carbonate (crosslinking agent) 0.6g, trimethylolpropane trimethyl Methyl acrylate (co-crosslinking agent) 0.7g, 3-methacryloxypropyltrimethoxysilane (coupling agent) 0.2g, bis(2,2,6,6-tetramethyl-4- Piperidinyl) sebacate (anti-aging additive) 0.3g.

[0074] Preparation:

[0075] Firstly, the components of the first skin layer are mixed, and then co-extruded with the components of the core layer at 100°C, and then the obtained co-extruded product is embossed, cooled, drawn and rolled to obtain the described Composite enca...

Embodiment 3

[0077] This embodiment provides a composite packaging adhesive film and a preparation method thereof.

[0078] Wherein, the composite packaging adhesive film includes a core layer and a first skin layer.

[0079] The gross mass of described core layer is 100g, comprises following component: Surlyn resin 50g, PRIMACOR TM 10 50g.

[0080] The total mass of the first skin layer is 100g, including the following components: EVA resin 50g, POE resin 48.2g, tert-butyl peroxy-2-ethylhexyl carbonate (crosslinking agent) 0.6g, trimethylol Propane trimethacrylate (assistant crosslinking agent) 0.7g, 3-methacryloxypropyltrimethoxysilane (coupling agent) 0.2g, bis(2,2,6,6-tetramethyl -4-piperidinyl) sebacate (anti-aging additive) 0.3g.

[0081] Preparation:

[0082] First, the components of the first skin layer are mixed, and then co-extruded with the components of the core layer at 80°C, and then the obtained co-extruded product is embossed, cooled, drawn and rolled to obtain the des...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com